Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Needle Bar Molder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

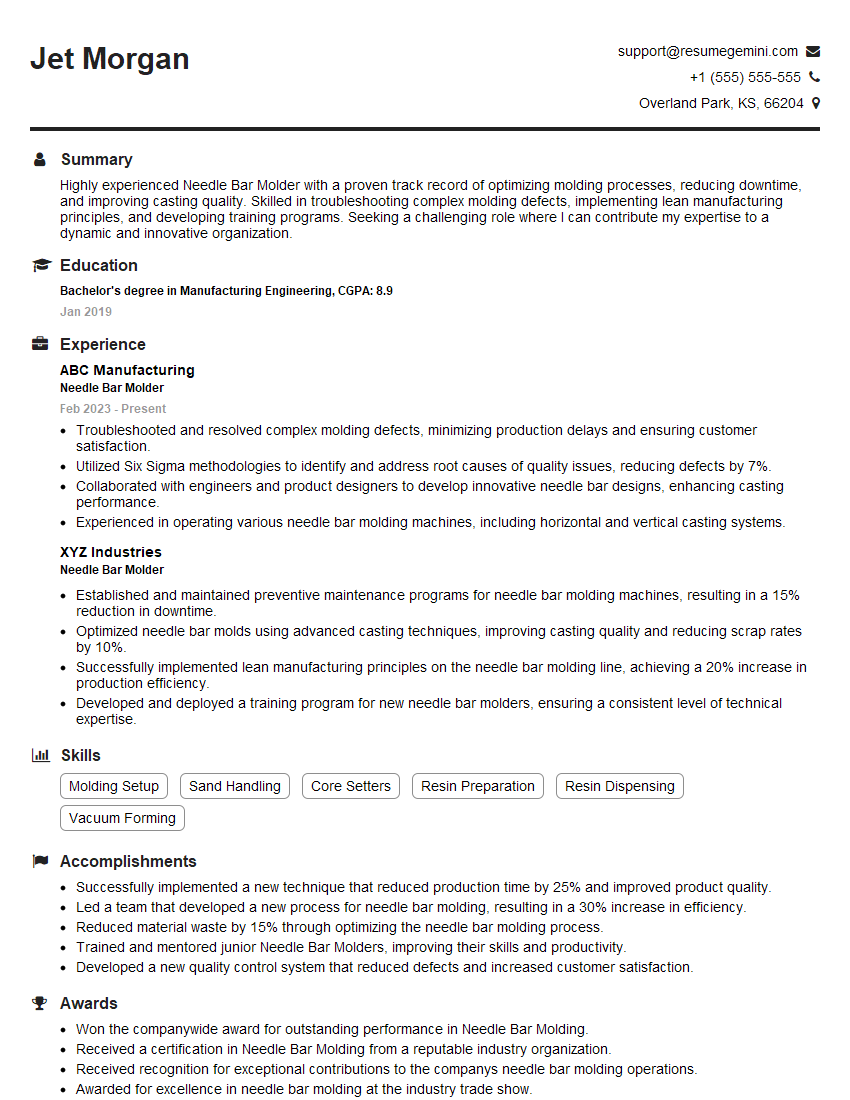

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Needle Bar Molder

1. Explain the process of needle bar molding in detail.

Needle bar molding is a casting process used to manufacture knitting machine needles. It involves the following steps:

- Pattern Making: A pattern of the needle is created using computer-aided design (CAD) software.

- Mold Preparation: A mold is prepared based on the pattern, consisting of two halves that form the cavity for the needle.

- Metal Preparation: The molten metal (usually steel) is prepared and degassed to remove impurities.

- Casting: The molten metal is poured into the mold cavity and allowed to solidify.

- Cooling: The mold is cooled to allow the metal to solidify completely.

- Ejection: The finished needle is ejected from the mold.

- Finishing: The needle is subjected to various finishing operations, such as heat treatment, grinding, and polishing.

2. What are the key factors that affect the quality of needle bars?

Dimensional Accuracy

- Precision of the mold

- Accuracy of the casting process

- Shrinkage during cooling

Surface Quality

- Smoothness and finish of the mold

- Absence of defects such as burrs, cracks, and inclusions

- Proper heat treatment and polishing

Material Properties

- Composition, alloying elements, and grain structure

- Hardness, strength, and toughness

- Corrosion resistance

3. How do you ensure that the needle bars meet the specified dimensions and tolerances?

To ensure dimensional accuracy, I follow these steps:

- Rigorous Mold Design: I use CAD software to create precise mold designs that adhere to the specified dimensions.

- Mold Inspection: I inspect the molds regularly to ensure that they are free from defects and maintain their accuracy.

- Casting Process Control: I closely monitor the casting process to control factors such as temperature, pressure, and cooling rate, which affect dimensional stability.

- Precision Measurement: I employ high-precision measuring instruments, such as coordinate measuring machines (CMMs), to verify the dimensions of the finished needle bars.

- Statistical Process Control (SPC): I implement SPC techniques to track and analyze data related to dimensional accuracy, identifying and addressing any variations.

4. What techniques do you use to improve the surface quality of needle bars?

To enhance surface quality, I utilize the following techniques:

- Precision Grinding: I use advanced grinding machines to precisely remove excess material and create a smooth, uniform surface.

- Polishing: I employ various polishing techniques, such as mechanical polishing and electrochemical polishing, to further refine the surface finish.

- Chemical Treatment: I apply chemical treatments, like pickling and passivation, to remove impurities and protect the surface from corrosion.

- Ultrasonic Cleaning: I use ultrasonic cleaning equipment to thoroughly remove any remaining particles or contaminants from the surface.

5. How do you choose the appropriate material for needle bars?

When selecting the material for needle bars, I consider the following factors:

- Strength and Hardness: The material must possess high strength and hardness to withstand the wear and tear of knitting operations.

- Toughness: The material should have good toughness to resist bending and impact forces.

- Corrosion Resistance: The material must be resistant to corrosion in the operating environment.

- Weldability: If the needle bars require welding, the material must have good weldability.

- Cost and Availability: I also consider the cost and availability of different materials.

6. Describe the steps involved in heat treating needle bars.

Heat treatment of needle bars typically involves the following steps:

- Annealing: The needle bars are heated to a high temperature and then slowly cooled to relieve internal stresses and improve ductility.

- Hardening: The needle bars are heated to a higher temperature and then rapidly cooled (quenched) to increase their hardness.

- Tempering: The hardened needle bars are reheated to a lower temperature and then tempered to reduce brittleness and improve toughness.

7. How do you ensure the quality and consistency of needle bars throughout the production process?

To maintain quality and consistency, I implement the following measures:

- Raw Material Inspection: I inspect the incoming raw materials to ensure they meet the required specifications.

- Process Control: I closely monitor each step of the production process, using statistical process control techniques to identify and minimize variations.

- Regular Calibration: I regularly calibrate all equipment and instruments used in the production process.

- Quality Testing: I perform rigorous quality testing throughout the production process, including dimensional inspection, surface analysis, and mechanical testing.

- Continuous Improvement: I actively seek opportunities for improvement and implement changes to optimize the production process and enhance needle bar quality.

8. What are some of the potential challenges in needle bar molding and how do you address them?

Porosity and Inclusions

I minimize porosity and inclusions by using high-quality raw materials, controlling casting conditions, and employing degassing techniques.

Dimensional Accuracy

I ensure dimensional accuracy by using precision molds, controlling casting parameters, and implementing rigorous measurement and inspection procedures.

Surface Defects

I prevent surface defects by optimizing the mold surface finish, using proper casting techniques, and employing appropriate post-casting treatments.

9. How do you stay up-to-date with the latest advancements in needle bar molding technology?

To stay current with advancements, I actively participate in industry conferences, read technical publications, and engage in research and development activities. I also collaborate with experts and suppliers to learn about new techniques and materials.

10. What are your strengths and weaknesses as a Needle Bar Molder?

Strengths

- Thorough understanding of needle bar molding processes

- Expertise in mold design and optimization

- Proven track record of producing high-quality needle bars

- Strong analytical and problem-solving skills

Weaknesses

- Limited experience with certain specialized needle bar designs

- Would benefit from additional training on advanced quality control techniques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Needle Bar Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Needle Bar Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Needle Bar Molders play a crucial role in ensuring smooth functioning of knitting machines by producing high-quality needle bars.

1. Molding Needle Bars

This involves operating specialized molding machines to cast molten metal into molds that create the shape of needle bars.

- Monitor mold temperature and pressure to ensure proper casting.

- Inspect castings for any defects or imperfections.

2. Setting Up Molding Equipment

Proper setup of molding equipment is essential for efficient production.

- Install and align molds.

- Calibrate and maintain temperature and pressure settings.

3. Maintaining Manufacturing Environment

A clean and well-maintained work area is key to ensuring quality output.

- Keep molding machines and equipment in good working order.

- Maintain a clean and organized work area to prevent contamination.

4. Quality Assurance

Needle Bar Molders are responsible for ensuring that produced needle bars meet specified standards and quality requirements.

- Test needle bars for dimensions, tolerances, and performance.

- Identify and correct any deviations from required specifications.

Interview Tips

Preparing for a Needle Bar Molder interview can increase your chances of success. Here are some essential tips and hacks:

1. Research the Company and Role

Familiarize yourself with the company’s history, products, and culture. Understand the specific requirements of the Needle Bar Molder role.

- Visit the company website and read industry-related publications.

- Connect with current or former employees on LinkedIn for insights.

2. Highlight Relevant Skills and Experience

Tailor your resume and interview responses to emphasize skills and experience that align with the job responsibilities. Quantify your accomplishments whenever possible.

- Demonstrate your expertise in molding techniques, equipment operation, and quality control.

- Provide specific examples of how you have improved production efficiency or reduced defects.

3. Practice Common Interview Questions

Prepare for common interview questions by researching and rehearsing your answers. This will help you articulate your skills and qualifications confidently.

- Prepare for questions about your molding experience, troubleshooting abilities, and attention to detail.

- Consider behavioral questions that explore how you have handled challenges or worked in a team.

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview shows your interest and engagement. It also gives you an opportunity to clarify any remaining doubts.

- Inquire about the company’s commitment to quality and innovation.

- Ask about opportunities for professional development and career growth.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Needle Bar Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!