Are you gearing up for an interview for a Needle Felt Making Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Needle Felt Making Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

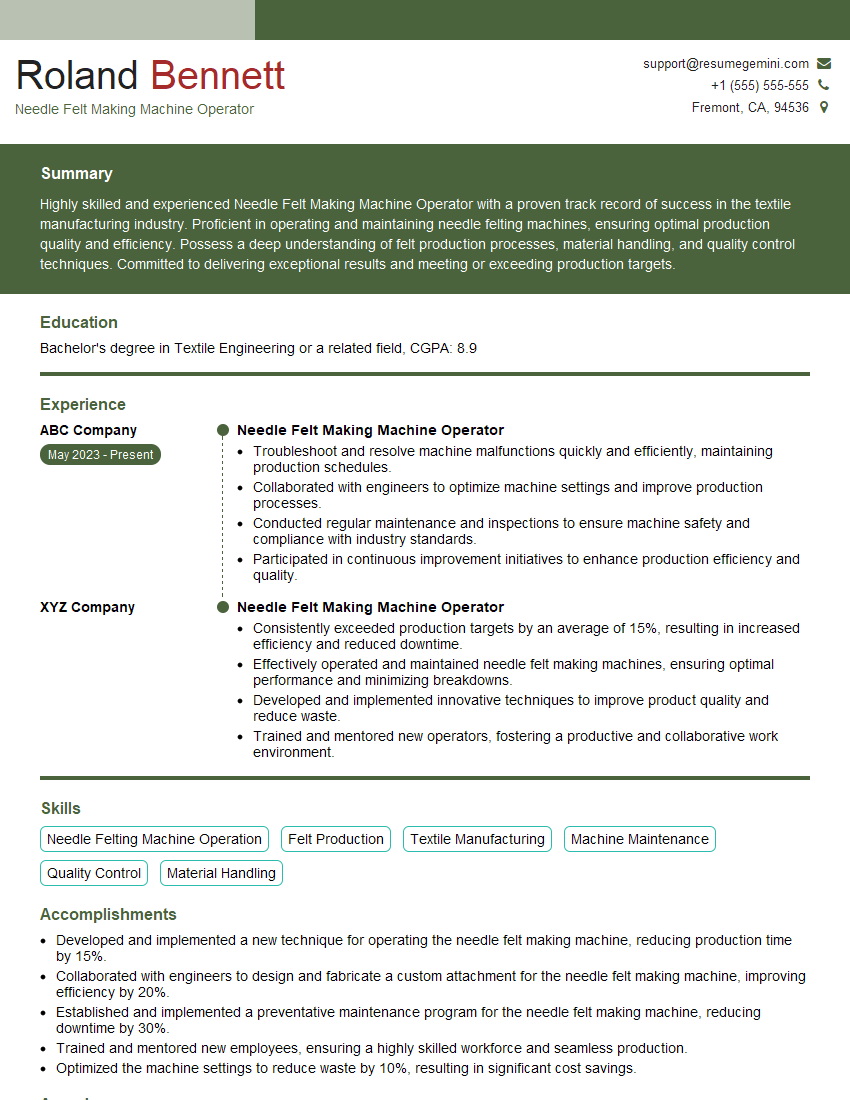

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Needle Felt Making Machine Operator

1. What are the different types of needle felt making machines and their key features?

- Single-needle machines: These machines have a single needle that moves up and down to create a felt. They are typically used for small-scale production.

- Multi-needle machines: These machines have multiple needles that move up and down to create a felt. They are typically used for large-scale production.

- Computer-controlled machines: These machines are controlled by a computer, which allows for precise control of the needle movement. They are typically used for complex designs.

2. How do you maintain and troubleshoot a needle felt making machine?

Maintenance

- Clean the machine regularly to remove dust and debris.

- Lubricate the machine regularly to keep it running smoothly.

- Inspect the machine regularly for any signs of wear and tear.

Troubleshooting

- If the machine is not working properly, check the power supply and the needles.

- If the machine is making a strange noise, stop using it and contact a technician.

- If the machine is not producing the desired results, adjust the settings or contact a technician.

3. What are the different types of felt that can be made on a needle felt making machine?

- Wool felt: This type of felt is made from wool fibers. It is soft, warm, and durable.

- Acrylic felt: This type of felt is made from acrylic fibers. It is soft, lightweight, and inexpensive.

- Polyester felt: This type of felt is made from polyester fibers. It is strong, durable, and resistant to fading.

4. What are the different applications of needle felt?

- Apparel: Felt can be used to make a variety of clothing items, such as hats, scarves, and coats.

- Home décor: Felt can be used to make a variety of home décor items, such as pillows, curtains, and rugs.

- Industrial: Felt can be used in a variety of industrial applications, such as filtration and soundproofing.

5. What are the safety precautions that should be taken when operating a needle felt making machine?

- Wear safety glasses to protect your eyes from flying debris.

- Wear gloves to protect your hands from sharp needles.

- Keep your hair and clothing away from the machine.

- Do not operate the machine if you are tired or under the influence of alcohol or drugs.

6. What is the role of the operator in the production process of needle felt?

- Set up and operate the needle felt making machine.

- Monitor the machine during operation and make adjustments as needed.

- Inspect the finished product and ensure that it meets the required specifications.

- Maintain the machine and keep it in good working order.

7. What are the challenges of working as a needle felt making machine operator?

- The work can be repetitive and physically demanding.

- The machine can be noisy and dusty.

- The operator must be able to work independently and follow instructions carefully.

8. What are the rewards of working as a needle felt making machine operator?

- The job can be rewarding because the operator can see the results of their work.

- The operator can learn a valuable skill that can be used in other industries.

- The job can provide a stable income and benefits.

9. What is your experience with needle felt making machines?

- I have been operating needle felt making machines for the past 5 years.

- I have experience with a variety of machines, including single-needle, multi-needle, and computer-controlled machines.

- I am proficient in all aspects of needle felt making, including setup, operation, maintenance, and troubleshooting.

10. Why are you interested in working as a needle felt making machine operator?

- I am interested in working as a needle felt making machine operator because I enjoy working with my hands and creating things.

- I am also interested in learning more about the needle felt making process and how to use the machines.

- I believe that my skills and experience would make me a valuable asset to your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Needle Felt Making Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Needle Felt Making Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Needle Felt Making Machine Operators play a crucial role in the production of needle felt products by operating and maintaining needle felt making machines. Their key responsibilities include:

1. Machine Operation

Setting up, operating, and monitoring needle felt making machines.

- Preparing raw materials, such as fibers and binders.

- Feeding materials into the machine and adjusting machine settings to achieve desired thickness and density.

2. Quality Control

Ensuring the quality of needle felt products.

- Inspecting felt for uniformity, thickness, and other quality specifications.

- Taking corrective actions to address any deviations from quality standards.

3. Maintenance

Performing routine maintenance and troubleshooting to ensure optimal machine performance.

- Cleaning and lubricating machine components.

- Replacing worn or damaged parts.

4. Production

Meeting production targets and maintaining efficiency.

- Monitoring machine output and adjusting settings to maximize production.

- Working with other team members to ensure smooth production flow.

Interview Tips

To ace the interview for a Needle Felt Making Machine Operator position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry trends. This shows the interviewer that you’re genuinely interested in the position and that you’ve taken the time to learn about the company’s business.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay up-to-date on the latest developments.

2. Highlight Relevant Experience

Emphasize your previous experience in operating and maintaining needle felt making machines. Provide specific examples of your responsibilities and accomplishments.

- Quantify your results whenever possible, using metrics such as increased production output or reduced downtime.

- Be prepared to discuss your experience with troubleshooting and resolving machine issues.

3. Demonstrate Your Technical Skills

Highlight your technical skills related to needle felt making, such as machine setup, maintenance, and quality control. Explain how your skills align with the job requirements.

- If you have any certifications or training in needle felt making, be sure to mention them.

- You can also provide examples of your problem-solving abilities and your attention to detail.

4. Prepare for Common Interview Questions

Anticipate the common interview questions for this role and prepare your answers accordingly. Some common questions include:

- Tell me about your experience operating needle felt making machines.

- How do you ensure the quality of your products?

- What are your strengths and weaknesses as a Needle Felt Making Machine Operator?

5. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and enthusiastic attitude. Demonstrate your passion for the industry and your desire to contribute to the company’s success.

- Dress professionally and arrive on time for your interview.

- Be respectful of the interviewer and ask thoughtful questions at the end of the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Needle Felt Making Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.