Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Needle Loom Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

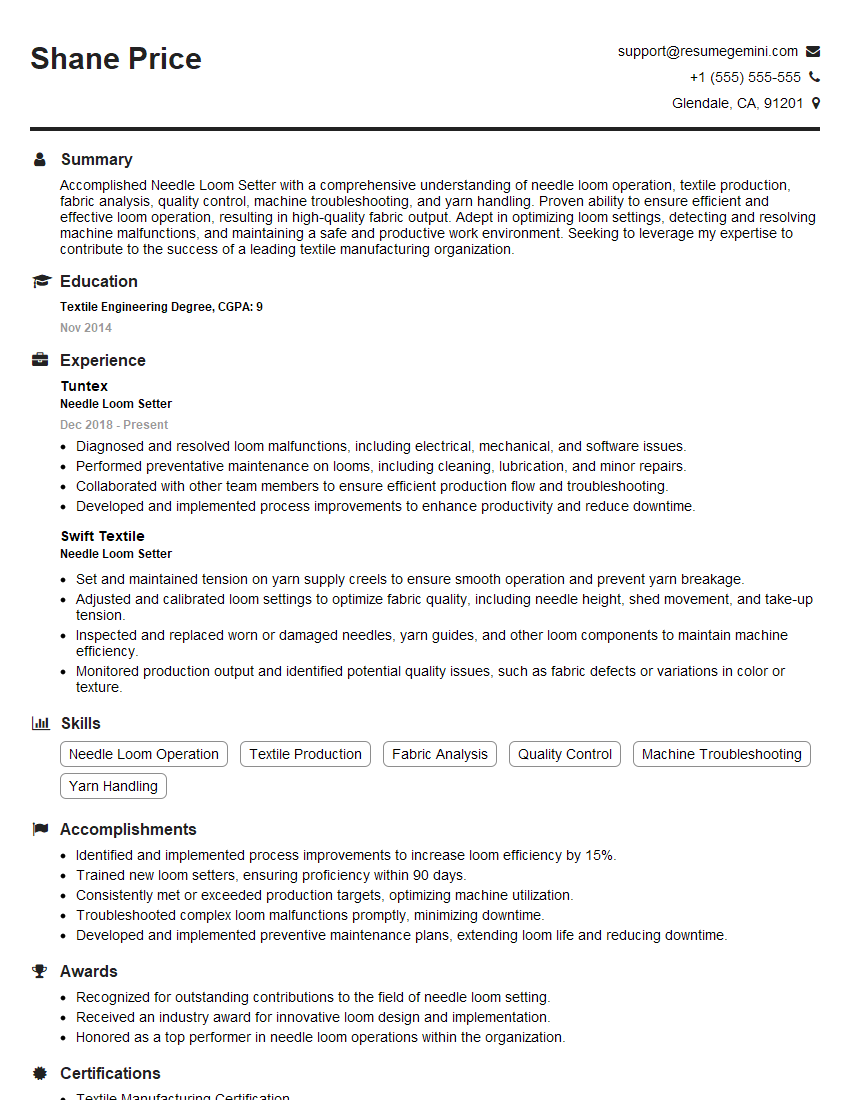

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Needle Loom Setter

1. How do you adjust the needle loom to achieve the desired fabric quality?

To adjust the needle loom for optimal fabric quality, I follow these steps:

- Assess the fabric specifications to determine the required needle size, spacing, and tension.

- Install and tension the needles precisely to create the desired stitch pattern.

- Set the loom speed and fabric tension to match the yarn type and fabric weight.

- Fine-tune the loom settings during weaving to ensure consistent fabric quality and prevent breakage.

- Monitor the fabric appearance and make adjustments as needed to maintain desired specifications.

2. Describe the process of threading a needle loom.

Threading the warp yarns:

- Warp the yarn onto the warp beam.

- Thread the warp yarns through the reed.

- Tie the warp yarns to the front and back beams.

Threading the weft yarns:

- Wind the weft yarn onto bobbins.

- Insert the bobbins into the shuttle.

- Thread the weft yarn through the needle eyes.

3. How do you troubleshoot common needle loom problems, such as yarn breakage or uneven fabric?

- Yarn breakage: Check needle tension, shuttle alignment, and yarn quality.

- Uneven fabric: Inspect needle spacing, warp and weft tension, and loom speed.

- Fabric defects: Identify and remove foreign objects, adjust needle height, and optimize weaving parameters.

- Machine malfunctions: Follow manufacturer’s guidelines for troubleshooting and repairs.

4. Explain the different types of needle looms and their applications.

- Flat needle loom: Produces flat fabrics like lace and embroidery.

- Circular needle loom: Creates tubular fabrics like socks and gloves.

- Raschel needle loom: Produces warp-knitted fabrics with intricate patterns.

- Tricot needle loom: Knits elastic fabrics like lingerie and swimwear.

5. How do you maintain and care for needle looms to ensure optimal performance?

- Regularly clean and lubricate all moving parts.

- Inspect needles for damage and replace as needed.

- Calibrate and adjust the loom settings periodically.

- Follow the manufacturer’s maintenance schedule for preventive care.

6. Describe your experience in using warp and weft yarns in needle loom operations.

- Selected and prepared warp and weft yarns based on fabric specifications.

- Calculated yarn tension and adjusted loom settings accordingly.

- Troubleshooted issues related to yarn quality and tension.

- Maintained optimal yarn tension throughout the weaving process.

7. How do you optimize needle loom production to meet deadlines and quality standards?

- Planned and scheduled work efficiently to maximize productivity.

- Minimized downtime by proactively troubleshooting and maintaining the loom.

- Collaborated with team members to streamline processes and improve workflow.

- Adhered to strict quality control measures to ensure consistent fabric quality.

8. Describe your experience in working with different needle loom materials, such as cotton, silk, and synthetic fibers.

- Handled a variety of yarn materials, including cotton, silk, nylon, and polyester.

- Adjusted loom settings and techniques based on the material’s properties.

- Troubleshooted issues related to yarn characteristics and compatibility.

- Produced high-quality fabrics from diverse materials.

9. How do you stay up-to-date with advancements in needle loom technology and industry best practices?

- Attended industry conferences and workshops.

- Read technical publications and research papers.

- Consulted with experts and visited other manufacturing facilities.

- Participated in training programs and received certifications.

10. What are the safety precautions and regulations that you follow when operating needle looms?

- Wear appropriate safety gear, including eye protection and gloves.

- Keep the work area clean and free of hazards.

- Follow machine lockout/tagout procedures.

- Be aware of the potential for moving parts and pinch points.

- Adhere to all safety protocols and report any unsafe conditions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Needle Loom Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Needle Loom Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Needle Loom Setters are responsible for setting up and maintaining needle looms, which are machines used to create fabrics. They must be able to read and interpret blueprints, and have a strong understanding of the mechanics of needle looms.

1. Set up and maintain needle looms

Needle Loom Setters are responsible for setting up and maintaining needle looms. This includes ensuring that the loom is level and properly lubricated, and that the needles are correctly aligned. They must also be able to troubleshoot and repair any problems that may arise.

- Set up and adjust needle looms according to specifications.

- Inspect and maintain looms to ensure proper operation.

- Troubleshoot and repair looms as needed.

2. Inspect and adjust fabric

Needle Loom Setters are responsible for inspecting the fabric produced by the loom to ensure that it meets quality standards. They must be able to identify and correct any defects, and make adjustments to the loom as needed.

- Inspect fabric for defects, such as broken threads or uneven stitching.

- Adjust loom settings to correct defects.

- Maintain records of loom adjustments and fabric quality.

3. Train and supervise other employees

Needle Loom Setters may be responsible for training and supervising other employees. They must be able to communicate effectively and provide clear instructions.

- Train new employees on loom operation and maintenance.

- Supervise other employees and ensure that they are following procedures.

- Provide guidance and support to other employees.

4. Keep records and reports

Needle Loom Setters are responsible for keeping records and reports on the operation of the loom. This includes tracking loom maintenance, fabric production, and any defects that may occur.

- Keep records of loom maintenance and repairs.

- Track fabric production and quality.

- Report any problems or defects to the supervisor.

Interview Tips

Interviews can be tough, but there are some things you can do to prepare and make the process easier. Here are a few tips to help you ace your next interview for a Needle Loom Setter position:

1. Research the company and the position

Before you go to an interview, it’s important to do your research. This means learning about the company, the position you’re applying for, and the industry. This will help you to answer questions intelligently and show the interviewer that you’re serious about the job.

- Visit the company’s website to learn about their history, products, and services.

- Read industry publications and news articles to stay up-to-date on the latest trends.

2. Practice your answers to common interview questions

There are certain questions that are commonly asked in interviews. It’s a good idea to practice your answers to these questions so that you can deliver them confidently and concisely.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with needle loom setting?

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This will show the interviewer that you’re respectful of their time and that you’re taking the interview seriously.

4. Be yourself and be confident

The most important thing is to be yourself and to be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Next Step:

Now that you’re armed with the knowledge of Needle Loom Setter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Needle Loom Setter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini