Are you gearing up for a career in Needle Punch Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Needle Punch Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

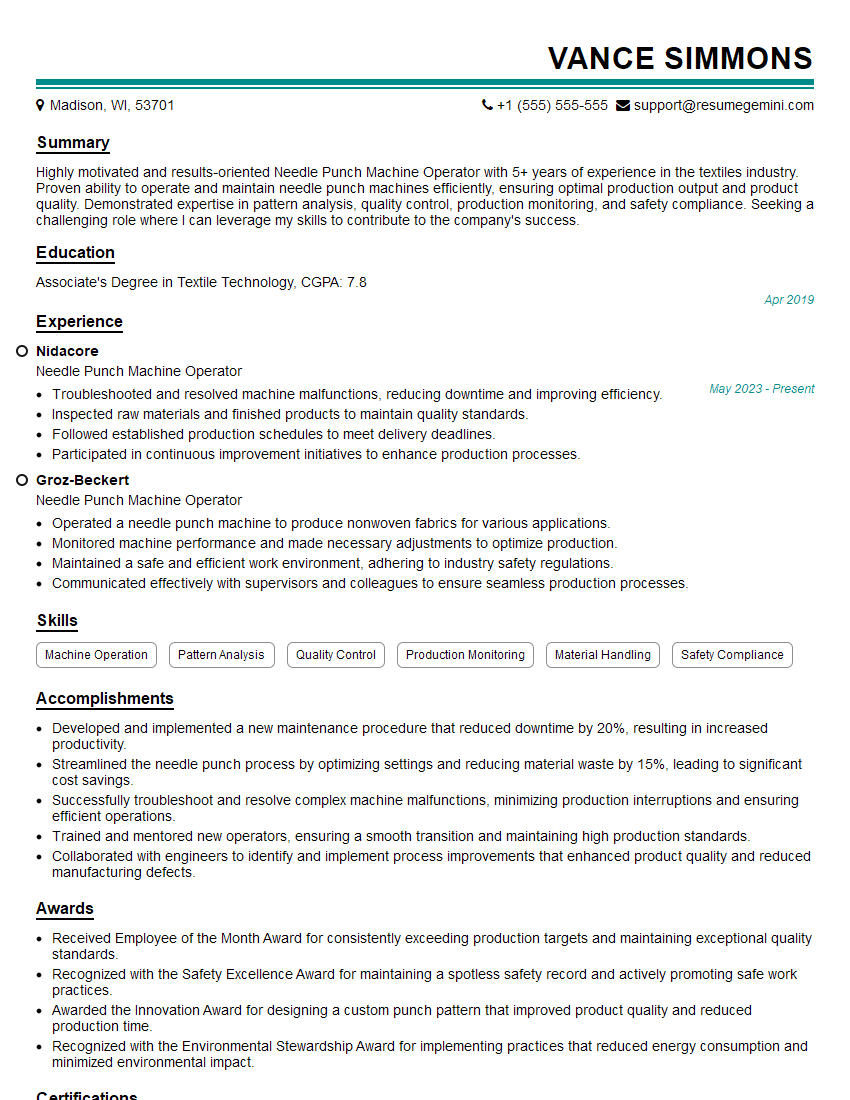

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Needle Punch Machine Operator

1. What are the key components of a needle punch machine and explain their functions?

The key components of a needle punch machine include:

- The frame: Supports and houses all other components of the machine.

- The punching head: Contains the needles that punch the fabric.

- The fabric feed system: Moves the fabric through the machine.

- The backing material feed system: Feeds the backing material, such as a scrim or felt, under the fabric.

- The suction system: Removes waste material from the machine.

2. Describe the process of needle punching and the factors that affect the quality of the finished product?

Materials

- The type of fabric being punched

- The type of backing material being used

Machine settings

- The speed of the punching head

- The number of needles in the punching head

- The depth of the needles

Environmental factors

- The temperature and humidity of the environment

3. What are the different types of needle punch machines and what are their respective advantages and disadvantages?

The three main types of needle punch machines are:

- Reciprocating needle punch machines: These machines have a punching head that moves up and down, punching the fabric with needles that are mounted on a reciprocating bar.

- Rotary needle punch machines: These machines have a punching head that rotates, punching the fabric with needles that are mounted on a rotating drum.

- Oscillating needle punch machines: These machines have a punching head that oscillates back and forth, punching the fabric with needles that are mounted on an oscillating bar.

4. What are the maintenance procedures required to keep a needle punch machine running optimally?

The following are some of the maintenance procedures that are required to keep a needle punch machine running optimally:

- Daily maintenance:

- Clean the machine of any dust or debris.

- Inspect the needles for damage and replace any that are broken or bent.

- Lubricate the moving parts of the machine.

- Weekly maintenance:

- Clean the suction system.

- Inspect the fabric feed system and backing material feed system for any damage.

- Calibrate the machine.

- Monthly maintenance:

- Inspect the electrical system.

- Inspect the hydraulic system.

- Perform a full system check.

5. What are the safety precautions that must be observed when operating a needle punch machine?

The following are some of the safety precautions that must be observed when operating a needle punch machine:

- Wear appropriate safety gear, such as safety glasses, earplugs, and gloves.

- Keep hands and other body parts away from the moving parts of the machine.

- Never operate the machine when it is not properly guarded.

- Be aware of the hazards associated with the materials being used.

- Follow all manufacturer’s instructions for safe operation.

6. How do you troubleshoot common problems that may occur with a needle punch machine?

Some common problems that may occur with a needle punch machine include:

- The machine is not punching the fabric properly: This could be due to a number of factors, such as the needles being dull, the fabric being too thick, or the machine being out of calibration.

- The machine is making excessive noise: This could be due to a number of factors, such as the machine being out of balance, the bearings being worn, or the gears being damaged.

- The machine is leaking oil: This could be due to a number of factors, such as a leak in the hydraulic system or a damaged seal.

7. What are the quality control procedures that you would implement to ensure that the finished product meets customer specifications?

The following are some of the quality control procedures that could be implemented to ensure that the finished product meets customer specifications:

- Inspect the raw materials: Ensure that the fabric and backing material meet the required specifications.

- Set up the machine: Calibrate the machine and ensure that it is running properly.

- Monitor the production process: Regularly inspect the fabric and backing material as it is being punched.

- Inspect the finished product: Check the finished product for any defects, such as holes, tears, or uneven punching.

8. What are your thoughts on the future of the needle punch industry?

The future of the needle punch industry looks bright. The demand for needle-punched fabrics is growing, as these fabrics are used in a wide range of applications, such as automotive interiors, furniture, and filtration.

- Increased demand for needle-punched fabrics: The demand for needle-punched fabrics is expected to grow in the coming years, as these fabrics offer a number of advantages over other types of fabrics, such as durability, breathability, and sound absorption.

- New applications for needle-punched fabrics: Needle-punched fabrics are being used in a wider range of applications, such as medical devices, construction materials, and geotextiles.

- Technological advancements: Technological advancements are making needle punch machines more efficient and productive.

9. What are your strengths and weaknesses as a needle punch machine operator?

Some of my strengths as a needle punch machine operator include:

- I have a strong understanding of the needle punch process and the different factors that affect the quality of the finished product.

- I am able to operate a needle punch machine safely and efficiently.

- I am a team player and am able to work well with others.

Some of my weaknesses as a needle punch machine operator include:

- I am relatively new to the needle punch industry and do not have as much experience as some other operators.

- I am not as familiar with the latest needle punch machines as I would like to be.

10. Why should we hire you as a needle punch machine operator?

I believe that I am the best candidate for this position because I have the skills, experience, and motivation to be a successful needle punch machine operator.

- Skills: I have a strong understanding of the needle punch process and the different factors that affect the quality of the finished product. I am also able to operate a needle punch machine safely and efficiently.

- Experience: I have two years of experience operating a needle punch machine in a production environment.

- Motivation: I am a hard worker and I am always looking for ways to improve my skills and knowledge. I am also passionate about the needle punch industry and I am excited about the opportunity to work for your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Needle Punch Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Needle Punch Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Needle Punch Machine Operators are responsible for operating and maintaining needle punch machines, which are used to create nonwoven fabrics. These fabrics are used in a variety of products, including carpets, automotive interiors, and filters.

1. Set up and operate needle punch machines

To set up a needle punch machine, the operator must first load the machine with the desired fabric. The operator must then adjust the machine’s settings, such as the speed of the needles and the depth of the punches. Once the machine is set up, the operator can start the machine and monitor its operation.

2. Inspect and maintain needle punch machines

Needle punch machines require regular inspection and maintenance to ensure that they are operating properly. Operators must check the machines for any signs of wear or damage. They must also clean and lubricate the machines regularly.

3. Troubleshoot and repair needle punch machines

If a needle punch machine breaks down, the operator must troubleshoot the problem and repair the machine. Operators must be able to identify the source of the problem and make the necessary repairs. They must also be able to adjust the machine’s settings to prevent the problem from recurring.

4. Follow safety procedures

Needle punch machines can be dangerous if they are not operated properly. Operators must follow all safety procedures, such as wearing protective clothing and eyewear. They must also be aware of the potential hazards of the machine, such as the risk of being struck by a needle.

Interview Tips

Preparing for an interview can be nerve-wracking, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to learn about the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to practice answering these questions in a clear and concise way.

3. Dress appropriately

First impressions matter, so make sure you dress appropriately for your interview. This means wearing clean, pressed clothes that are appropriate for the company culture.

4. Be on time

Punctuality is important, so make sure you arrive on time for your interview. If you are running late, call the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Needle Punch Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!