Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Nicking Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

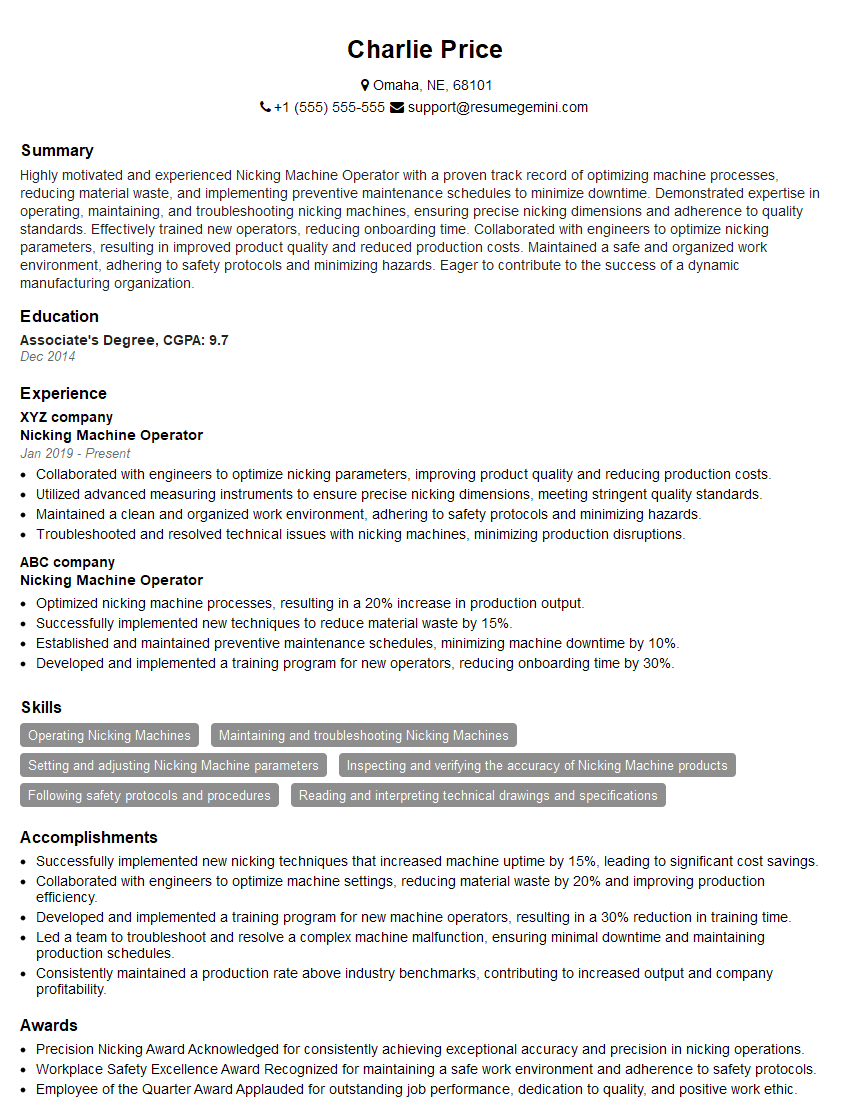

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nicking Machine Operator

1. What are the key responsibilities of a Nicking Machine Operator?

As a Nicking Machine Operator, I would be responsible for:

- Setting up and operating the nicking machine to create precision nicks or cuts in a variety of materials.

- Inspecting the materials before and after nicking to ensure quality and accuracy.

- Measuring and marking the materials according to the required specifications.

- Maintaining the nicking machine and ensuring its smooth operation.

- Following safety protocols and wearing appropriate protective gear during operation.

2. Describe the different types of nicks that can be made using a nicking machine?

Types of Nicks

- V-Nick: A V-shaped nick used for bending or folding materials.

- U-Nick: A U-shaped nick used for creating precise cuts or separating materials.

- Straight Nick: A straight-line nick used for cutting or scoring materials.

- Circular Nick: A circular nick used for creating round or curved cuts.

- Combination Nick: A combination of different nick types to achieve specific results.

3. What factors should be considered when selecting the appropriate nicking tool?

When selecting the appropriate nicking tool, several factors must be considered:

- Material Type: Different materials require specific nicking tools designed for their properties.

- Nick Size and Shape: The size and shape of the desired nick determine the type of tool required.

- Accuracy and Precision: The required level of accuracy and precision influences the choice of tool.

- Machine Compatibility: The nicking tool must be compatible with the available nicking machine.

- Tool Wear and Maintenance: The durability and maintenance requirements of the tool should be considered.

4. How do you ensure the accuracy and consistency of nicking operations?

To ensure accuracy and consistency, I follow these steps:

- Calibration and Maintenance: I regularly calibrate and maintain the nicking machine to ensure precise measurements.

- Material Preparation: I carefully prepare and inspect the materials to ensure they are flat and free of defects.

- Precise Setup: I meticulously set up the machine according to the required specifications, including nicking depth and spacing.

- Tool Inspection: I inspect the nicking tool before and during operation to ensure it is sharp and in good condition.

- Quality Control: I regularly check the nicked materials for accuracy and quality, making adjustments as needed.

5. What are the safety precautions that must be observed when operating a nicking machine?

For safe operation, I adhere to these safety precautions:

- PPE: I always wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection.

- Machine Inspection: I inspect the machine before each use, checking for any potential hazards or damage.

- Proper Operation: I operate the machine according to the manufacturer’s instructions and only when it is in good working order.

- Work Area Safety: I maintain a clean and organized work area, free of tripping hazards or obstructions.

- Emergency Procedures: I am familiar with the emergency procedures and know how to respond to potential accidents or malfunctions.

6. How do you troubleshoot common problems that may arise during nicking operations?

To troubleshoot common problems, I follow these steps:

- Identify the Issue: I carefully examine the machine, materials, and nicking results to identify the root cause of the problem.

- Check Settings: I verify that the machine settings, including nicking depth and spacing, are correct.

- Inspect Tool: I inspect the nicking tool for wear or damage and replace it if necessary.

- Adjust Machine: I make necessary adjustments to the machine, such as tension or calibration, to optimize performance.

- Test and Monitor: I conduct test nicks and monitor the results to ensure the problem has been resolved.

7. What maintenance procedures are required to keep the nicking machine in optimal condition?

For optimal machine performance, I perform the following maintenance procedures:

- Regular Cleaning: I regularly clean the machine, removing any debris or dust that may accumulate.

- Lubrication: I lubricate moving parts according to the manufacturer’s specifications.

- Inspection and Calibration: I inspect and calibrate the machine at regular intervals to ensure accuracy and precision.

- Tool Maintenance: I maintain and sharpen the nicking tools to ensure they remain in good condition.

- Record Keeping: I keep records of all maintenance activities for future reference and to track machine performance.

8. How do you stay up-to-date with the latest advancements in nicking machine technology?

To stay current with advancements, I employ these strategies:

- Industry Publications: I read industry publications and journals to learn about new technologies and techniques.

- Conferences and Exhibitions: I attend industry conferences and exhibitions to connect with experts and explore new equipment.

- Online Research: I conduct online research to stay informed about the latest innovations and best practices.

- Training and Workshops: I participate in training programs and workshops to enhance my skills and learn about new technologies.

- Networking: I network with other professionals in the field to exchange knowledge and stay updated on industry trends.

9. What are the challenges you have faced as a Nicking Machine Operator, and how did you overcome them?

Challenge 1: Maintaining Accuracy and Consistency

- Solution: Implemented a rigorous quality control process, including regular machine calibration and material inspection.

Challenge 2: Troubleshooting Complex Problems

- Solution: Developed a systematic approach to problem-solving, involving thorough examination of the machine, materials, and settings.

Challenge 3: Meeting Production Deadlines

- Solution: Optimized machine settings and implemented efficient work practices, while maintaining quality standards.

10. Why are you interested in this Nicking Machine Operator position?

I am eager to join your team as a Nicking Machine Operator because:

- Passion for Precision: I am passionate about precision and accuracy, and nicking operations align perfectly with my skills.

- Technical Expertise: My technical expertise in nicking machine operation and maintenance makes me a suitable candidate for this role.

- Growth Opportunity: I am keen on contributing to your company’s success and see this position as an opportunity for professional growth.

- Team Environment: I believe in teamwork and am excited to collaborate with your team to achieve exceptional results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nicking Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nicking Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nicking Machine Operators are responsible for operating and maintaining nicking machines, which are used to create small cuts or nicks in the edges of materials. They work in a variety of industries, including paper, plastic, and metalworking.

1. Setting Up and Operating the Nicking Machine

Operators must first set up the nicking machine according to the specifications of the job. This includes setting the machine’s speed, depth of cut, and other parameters. Once the machine is set up, the operator can begin the nicking process.

- Loading and unloading materials into and out of the machine

- Adjusting the machine’s settings to ensure that the nicks are made to the correct specifications

- Monitoring the machine’s operation and making sure that the nicks are made consistently

2. Inspecting the Nicks

Once the nicking process is complete, the operator must inspect the nicks to make sure that they meet the required standards. This may involve using a microscope or other measuring device to check the size, depth, and other characteristics of the nicks.

- Using a microscope or other measuring device to check the size, depth, and other characteristics of the nicks

- Identifying and correcting any defects in the nicks

- Maintaining a record of the inspection results

3. Maintaining the Nicking Machine

Nicking machine operators must also perform regular maintenance on the machine to ensure that it is operating properly. This may include cleaning the machine, lubricating the moving parts, and replacing worn or damaged parts.

- Cleaning the machine and its components

- Lubricating the moving parts

- Replacing worn or damaged parts

- Performing regular maintenance checks to identify potential problems

4. Troubleshooting

If a nicking machine is not operating properly, the operator must be able to troubleshoot the problem and make repairs. This may involve identifying the source of the problem, replacing parts, or making adjustments to the machine’s settings.

- Identifying the source of the problem

- Replacing parts

- Making adjustments to the machine’s settings

Interview Tips

Interviews are generally categorized into two segments: Pre-Interview and Post-Interview process. A well prepared candidate can crack the code in any interview. Here are some interview tips and hacks that can help you ace your next Nicking Machine Operator interview:

1. Research the company and the position

Before you go on an interview, it is important to do your research on the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals. It will also help you to tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read the company’s social media pages

- Talk to people who work at the company

2. Practice answering common interview questions

There are a number of common interview questions that you can expect to be asked. It is a good idea to practice answering these questions in advance so that you can deliver confident and well-thought-out responses.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Why should we hire you?

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing anything too revealing or too casual.

- Wear a suit or dress

- Make sure your clothes are clean and pressed

- Avoid wearing anything too revealing or too casual

4. Be confident

Confidence is key in an interview. Believe in yourself and your abilities, and let the interviewer see that you are confident in your ability to do the job. This does not mean being arrogant or overbearing, but it does mean being assertive and positive.

- Make eye contact with the interviewer

- Speak clearly and confidently

- Avoid using filler words such as “um” and “ah”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nicking Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.