Feeling lost in a sea of interview questions? Landed that dream interview for Nipping Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Nipping Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

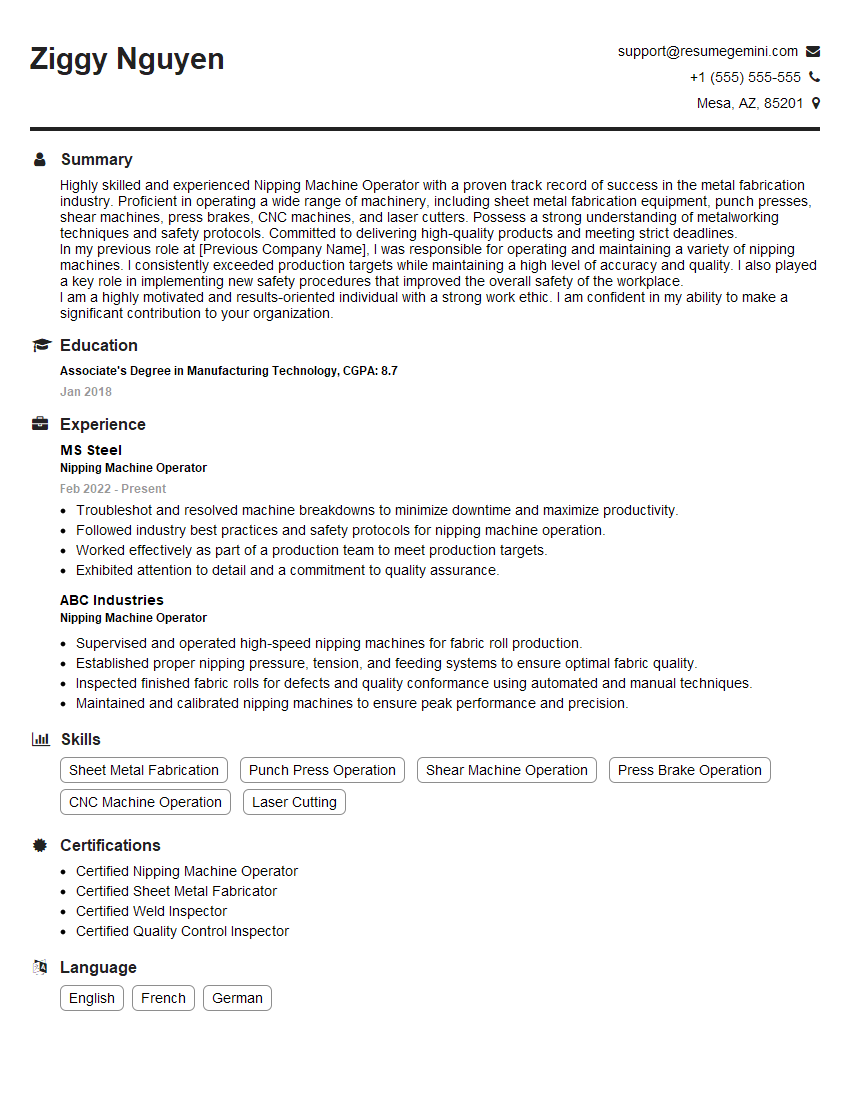

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nipping Machine Operator

1. What are the key responsibilities of a Nipping Machine Operator?

As a Nipping Machine Operator, I am responsible for:

- Operating and maintaining nipping machines to cut and shape fabrics

- Inspecting materials and ensuring they meet quality standards

- Making adjustments to the machine as needed to ensure optimal performance

- Troubleshooting and resolving any technical issues that arise

- Following safety protocols and maintaining a clean and organized work area

2. What are the different types of nipping machines and their applications?

Hydraulic Nipping Machines

- Powerful and precise cutting

- Used for cutting thick and heavy materials

Pneumatic Nipping Machines

- Faster cutting speeds

- Suitable for cutting thinner materials

Manual Nipping Machines

- Lower cutting force

- Used for cutting small or delicate materials

3. What are the safety precautions that must be taken when operating a nipping machine?

- Wear appropriate safety gear, including gloves, eye protection, and protective clothing

- Ensure the machine is properly grounded and maintained

- Keep hands and body parts away from the cutting area

- Never operate the machine if it is malfunctioning

- Follow all manufacturer’s instructions and safety protocols

4. How do you diagnose and troubleshoot common nipping machine problems?

- Machine not cutting properly: Check blade sharpness, tension, and alignment

- Machine making excessive noise: Inspect bearings, gears, and other moving parts

- Machine leaking hydraulic fluid: Inspect hoses, seals, and connections

- Machine overheating: Check cooling system and ventilation

5. What are the techniques for optimizing cutting accuracy and efficiency?

- Use sharp and properly aligned blades

- Apply the correct cutting force and speed for the material being cut

- Ensure the material is properly positioned and clamped

- Minimize vibrations by using anti-vibration pads or mounts

- Regularly calibrate and maintain the machine

6. What are the different materials that can be cut using a nipping machine?

- Fabrics (natural and synthetic)

- Leather

- Rubber

- Plastics

- Composite materials

7. How do you ensure the quality of cut pieces?

- Inspect incoming materials for defects

- Use precise cutting parameters and settings

- Regularly monitor the cutting process and make adjustments as needed

- Conduct quality control checks on finished pieces

- Document and maintain records of quality inspections

8. How do you handle waste and ensure a clean work area?

- Collect and dispose of waste materials regularly

- Clean the machine and work area daily

- Inspect and replace worn or damaged parts

- Implement a preventive maintenance program

- Follow environmental regulations and guidelines

9. What are your strengths and areas for improvement as a Nipping Machine Operator?

Strengths

- Proven ability to operate and maintain nipping machines efficiently

- Excellent attention to detail and quality standards

- Strong troubleshooting and problem-solving skills

- Ability to work independently and as part of a team

Areas for Improvement

- Expand knowledge of different materials and their cutting properties

- Enhance communication and teamwork skills

10. How do you stay up-to-date with the latest technologies and best practices in nipping machine operation?

- Attend industry conferences and workshops

- Read trade publications and technical articles

- Consult with manufacturers and experts

- Participate in online forums and discussion groups

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nipping Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nipping Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Nipping Machine Operator plays a crucial role in the manufacturing industry, ensuring the efficient and precise cutting of materials.

1. Machine Operation

The primary responsibility of a Nipping Machine Operator is to operate and maintain the nipping machine efficiently. This involves:

- Loading and unloading materials into and from the machine

- Adjusting machine settings to ensure optimal cutting precision and efficiency

- Monitoring the machine’s performance and making necessary adjustments to maintain production quality

2. Quality Control

Quality control is paramount in this role. Nipping Machine Operators:

- Inspect materials before and after cutting to ensure they meet specifications

- Identify and resolve any issues that may arise during the cutting process

- Maintain accurate records of production and quality control procedures

3. Safety and Maintenance

Safety and maintenance are essential aspects of the job. Nipping Machine Operators:

- Follow all safety protocols and wear appropriate safety gear

- Perform routine maintenance and cleaning of the nipping machine

- Report any equipment malfunctions or safety concerns promptly

4. Communication and Teamwork

Effective communication and teamwork are vital in manufacturing. Nipping Machine Operators:

- Communicate with supervisors, engineers, and other team members to ensure smooth production

- Contribute to problem-solving and improvement initiatives

Interview Tips

Preparing for an interview is key to increasing your chances of success. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, thoroughly research the company, its products or services, and the specific requirements of the Nipping Machine Operator position. This will help you tailor your answers to the interviewer’s questions and demonstrate your genuine interest in the role.

2. Practice Your Responses

Take some time to practice answering common interview questions. Anticipate questions related to your experience, skills, and qualifications as a Nipping Machine Operator. Prepare specific examples that highlight your abilities and fit with the position.

3. Highlight Your Skills and Experience

Clearly articulate your skills, experience, and qualifications that match the key job responsibilities of the Nipping Machine Operator role. Use specific examples and quantifiable results to demonstrate your proficiency in operating nipping machines, ensuring quality control, and adhering to safety protocols.

4. Emphasize Safety and Attention to Detail

Emphasize your commitment to safety and attention to detail. Nipping machines are potentially hazardous, so highlight your understanding of safety protocols and your meticulous approach to ensuring the quality of the cut materials.

5. Prepare Questions for the Interviewer

Preparing questions to ask the interviewer demonstrates your engagement and interest in the position. Ask thoughtful questions about the company’s culture, growth opportunities, or specific aspects of the Nipping Machine Operator role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Nipping Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.