Are you gearing up for an interview for a Nitroglycerin Neutralizer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Nitroglycerin Neutralizer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

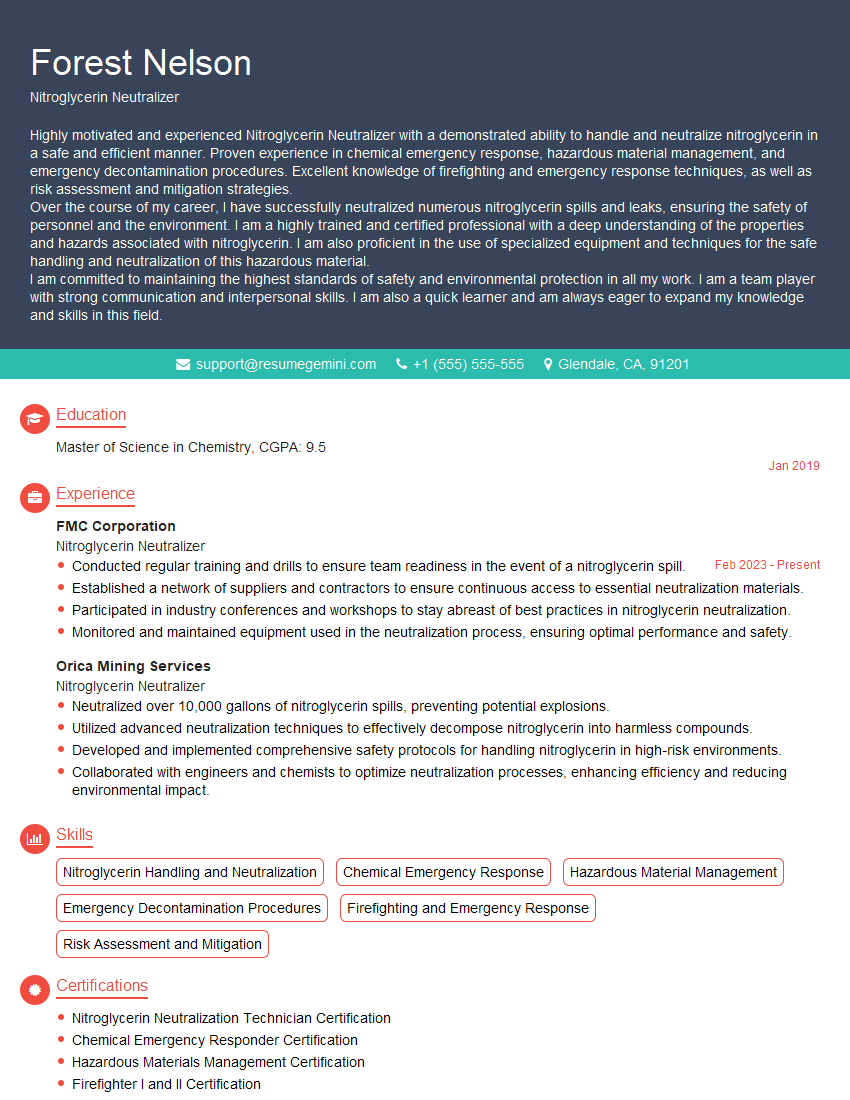

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nitroglycerin Neutralizer

1. Describe the key chemical reactions involved in the process of nitroglycerin neutralization?

In the process of nitroglycerin neutralization, nitroglycerin (C3H5N3O9) reacts with a neutralizing agent, typically sodium thiosulfate (Na2S2O3) or sodium carbonate (Na2CO3), to form less harmful compounds.

- Reaction with sodium thiosulfate: 2C3H5N3O9 + 5Na2S2O3 → 6NaNO3 + 2Na2SO4 + 2C3H6O3 + H2O

- Reaction with sodium carbonate: 2C3H5N3O9 + 3Na2CO3 → 6NaNO3 + 3CO2 + 2C3H6O3

2. What factors affect the rate of nitroglycerin neutralization?

Factors affecting the rate of nitroglycerin neutralization include:

- Concentration of neutralizing agent: Higher concentrations lead to faster neutralization.

- Temperature: Increased temperature accelerates the reaction rate.

- pH: Optimal pH ranges vary depending on the neutralizing agent used.

- Surface area of nitroglycerin: Smaller particles or thin films of nitroglycerin neutralize more rapidly.

- Presence of impurities: Impurities can interfere with the neutralization process.

3. How do you determine the effectiveness of nitroglycerin neutralization?

The effectiveness of nitroglycerin neutralization can be determined through various analytical methods:

- Visual inspection: Observe changes in the appearance, color, or texture of the nitroglycerin.

- Chemical tests: Use specific reagents, such as diphenylamine, to detect the presence of nitroglycerin or its reaction products.

- Instrumental analysis: Techniques like HPLC or GC-MS can provide quantitative data on nitroglycerin and its degradation products.

4. What safety precautions should be taken when handling nitroglycerin and its neutralized products?

Handling nitroglycerin and its neutralized products requires strict safety precautions:

- Personal protective equipment: Wear gloves, protective clothing, eye protection, and respirators.

- Proper ventilation: Ensure adequate ventilation to prevent exposure to toxic fumes.

- Storage and disposal: Store nitroglycerin and its neutralized products securely, and follow proper disposal protocols.

- Emergency response: Have an emergency response plan in place in case of spills or accidents.

- Training: Provide comprehensive training to personnel involved in handling these materials.

5. How do you dispose of nitroglycerin and its neutralized products safely?

Proper disposal of nitroglycerin and its neutralized products is crucial:

- Neutralization: Before disposal, neutralize nitroglycerin to reduce its explosive potential.

- Dilution: Dilute the neutralized solution with water to reduce its concentration.

- Incineration: Dispose of the diluted solution through licensed incineration facilities.

- Landfilling: Some neutralized products may be disposed of in hazardous waste landfills, subject to regulatory approvals.

- Biodegradation: Certain nitroglycerin derivatives can be biodegraded in controlled environments.

6. What are the potential environmental impacts of nitroglycerin and its neutralized products?

Nitroglycerin and its neutralized products can have environmental impacts if not handled and disposed of properly:

- Water contamination: Improper disposal can lead to groundwater and surface water contamination.

- Soil contamination: Spills or leaks can contaminate soil, affecting plant growth and soil organisms.

- Air pollution: Fumes and gases released during nitroglycerin neutralization and disposal can contribute to air pollution.

- Ecological effects: Nitroglycerin and its derivatives can be toxic to aquatic and terrestrial organisms.

7. What regulations govern the handling, storage, and disposal of nitroglycerin and its neutralized products?

Nitroglycerin and its neutralized products are subject to various regulations, including:

- OSHA: Occupational Safety and Health Administration regulations for handling and storage (29 CFR 1910.109)

- EPA: Environmental Protection Agency regulations for disposal (40 CFR 261.33)

- DOT: Department of Transportation regulations for transportation (49 CFR 173.54)

- Local regulations: Local authorities may have additional regulations and requirements.

8. What are the challenges and best practices in nitroglycerin neutralization and disposal?

Challenges:

- Explosive nature: Nitroglycerin is highly explosive, posing safety risks during handling.

- Environmental hazards: Improper disposal can lead to environmental contamination.

- Regulatory compliance: Navigating complex regulations can be challenging.

Best practices:

- Safety training: Ensure personnel are properly trained in handling nitroglycerin.

- Effective neutralization: Use appropriate neutralizing agents and procedures to minimize risks.

- Controlled disposal: Follow approved disposal methods to protect the environment.

- Record-keeping: Maintain detailed records of neutralization and disposal activities.

9. How do you stay up-to-date with the latest advancements in nitroglycerin neutralization and disposal technologies?

To stay current with industry advancements, I actively engage in the following activities:

- Attend conferences and workshops: Participate in industry events to learn about new techniques and innovations.

- Read technical publications and journals: Review recent research and articles related to nitroglycerin handling and disposal.

- Network with experts: Connect with professionals in the field to exchange knowledge and best practices.

- Attend webinars and online courses: Participate in educational programs to enhance my understanding of emerging technologies.

10. What are your strengths and weaknesses as a Nitroglycerin Neutralizer?

Strengths:

- Technical expertise: In-depth knowledge of nitroglycerin chemistry, neutralization reactions, and disposal methods.

- Safety consciousness: Prioritize safety in all aspects of nitroglycerin handling and disposal.

- Problem-solving skills: Ability to identify and address challenges during neutralization and disposal processes.

- Communication skills: Effectively communicate technical information to team members and stakeholders.

Weaknesses:

- Limited experience with large-scale operations: Primarily worked in smaller-scale nitroglycerin neutralization environments.

- Need for continuous training: As technology evolves, ongoing training is essential to stay up-to-date with best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nitroglycerin Neutralizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nitroglycerin Neutralizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nitroglycerin Neutralizers are responsible for safely and effectively neutralizing nitroglycerin, an explosive chemical used in various industrial and military applications. Their primary duties involve handling and neutralizing nitroglycerin in a controlled environment to prevent potential accidents or incidents.

1. Nitroglycerin Handling and Neutralization

Handle nitroglycerin in a safe and controlled manner, adhering to established safety protocols

- Wear appropriate protective gear (e.g., gloves, goggles, respirator)

- Operate neutralization equipment and follow neutralization procedures

- Dispose of neutralized nitroglycerin according to environmental regulations

2. Equipment Maintenance and Calibration

Maintain and calibrate neutralization equipment to ensure accuracy and optimal performance

- Inspect and clean equipment regularly

- Perform routine maintenance and repairs

- Calibrate equipment using standardized procedures

3. Safety Compliance and Reporting

Adhere to all safety regulations and reporting requirements related to nitroglycerin handling and neutralization

- Monitor and maintain a safe work environment

- Report any incidents or near-misses immediately

- Document and maintain accurate records of all neutralization activities

4. Training and Supervision

Train and supervise other employees on nitroglycerin handling and neutralization

- Provide clear instructions and demonstrations

- Monitor and evaluate employee performance

- Address any concerns or questions promptly

Interview Tips

To ace an interview for a Nitroglycerin Neutralizer position, it’s crucial to prepare thoroughly and showcase your knowledge and skills. Here are some tips to help you:

1. Research the Company and Role

Research the company and the specific role you’re applying for. Understand their industry, products or services, and safety protocols. This will help you tailor your answers to demonstrate your understanding of the job requirements.

- Visit the company website and read industry publications.

- Connect with current or former employees on LinkedIn.

2. Highlight Relevant Experience and Skills

Emphasize your experience in handling and neutralizing hazardous chemicals, especially nitroglycerin. If you have experience in safety compliance, equipment maintenance, or training, be sure to mention it.

- Quantify your accomplishments with specific numbers and metrics.

- Use action verbs to describe your responsibilities and results.

3. Prepare for Common Interview Questions

Practice answering common interview questions related to safety, compliance, and nitroglycerin handling. Here are some examples:

- Tell me about your experience in handling nitroglycerin.

- Describe a time you successfully neutralized a nitroglycerin spill.

- How do you maintain and calibrate neutralization equipment?

4. Ask Thoughtful Questions

Ask thoughtful questions during the interview to show your engagement and interest in the role. This can include questions about the company’s safety culture, training opportunities, or career advancement prospects.

- Ask about the company’s safety record and how they ensure employee well-being.

- Inquire about the opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nitroglycerin Neutralizer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!