Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Non-Destructive Evaluation Technician (NDE Technician) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Non-Destructive Evaluation Technician (NDE Technician) so you can tailor your answers to impress potential employers.

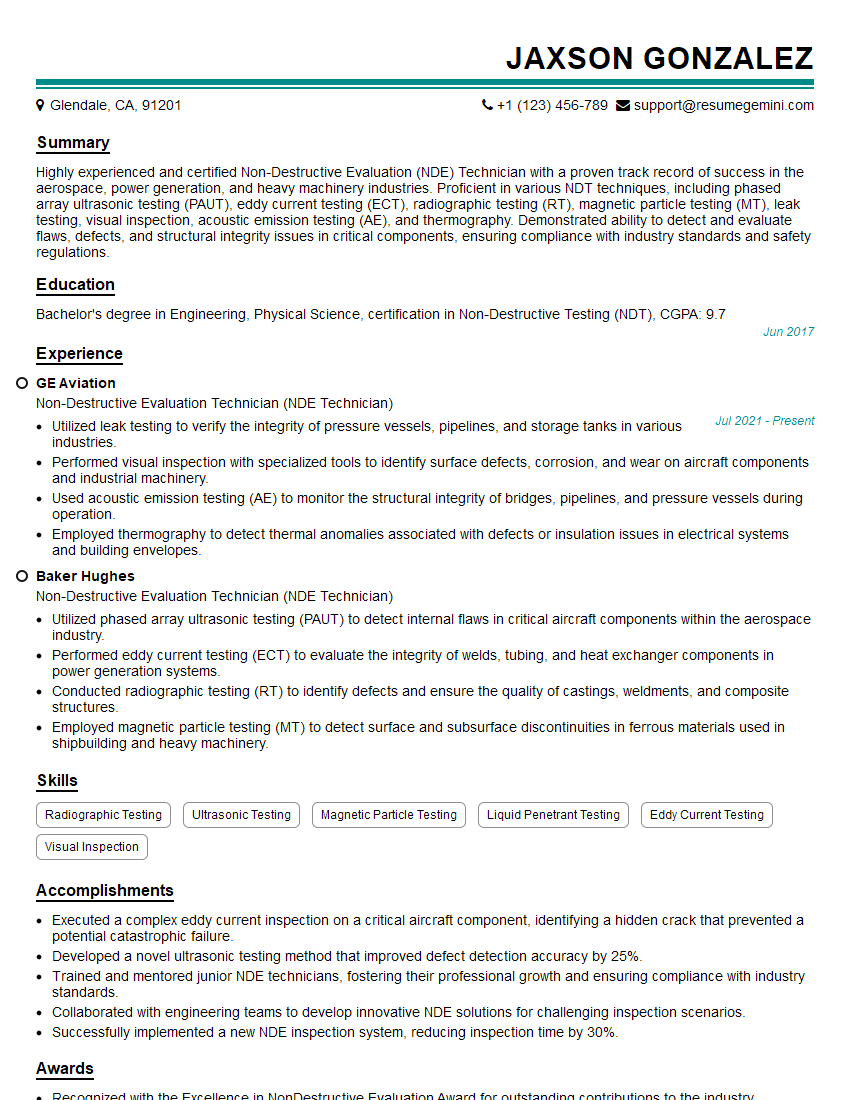

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Non-Destructive Evaluation Technician (NDE Technician)

1. Describe the principles behind the eddy current testing method?

Eddy current testing (ECT) is a non-destructive testing method that uses electromagnetic induction to detect and characterize defects in conductive materials. The basic principles of ECT are as follows:

- An alternating current (AC) is passed through a coil, creating a magnetic field.

- The magnetic field induces eddy currents in the test material.

- The eddy currents create their own magnetic field, which interacts with the original magnetic field.

- The interaction of the two magnetic fields causes changes in the impedance of the coil.

- These changes in impedance can be used to detect and characterize defects in the test material.

2. Explain the difference between ultrasonic testing (UT) and phased array ultrasonic testing (PAUT)?

Principles

- UT uses high-frequency sound waves to detect and characterize defects in materials.

- PAUT is a more advanced UT technique that uses multiple transducers to create a phased array of sound waves.

Advantages and Disadvantages

- UT is a relatively simple and inexpensive technique, but it can be difficult to interpret the results.

- PAUT is more expensive and complex than UT, but it provides a more detailed and accurate view of the material.

3. How do you calibrate and verify the accuracy of NDE equipment?

NDE equipment must be calibrated and verified regularly to ensure that it is accurate and reliable. The calibration process involves comparing the equipment’s readings to a known standard. The verification process involves checking the equipment’s readings against a known defect.

- Calibration is typically performed by a qualified technician using specialized equipment.

- Verification can be performed by the operator using simple test pieces.

4. What are the different types of NDE reports and what information should they include?

There are several different types of NDE reports, each with its own specific purpose and content. Some of the most common types of NDE reports include:

- Inspection reports document the results of an NDE inspection, including the type of inspection, the equipment used, the findings, and the conclusions.

- Evaluation reports provide an assessment of the significance of the NDE findings and recommend any necessary corrective actions.

- Repair reports document the repairs that have been made to an item following an NDE inspection.

All NDE reports should include the following information:

- The date of the inspection

- The name of the inspector

- The type of inspection

- The equipment used

- The findings

- The conclusions

5. What are the safety precautions that must be taken when performing NDE?

NDE can be a hazardous activity, so it is important to take the necessary safety precautions. Some of the most important safety precautions include:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat.

- Using the equipment properly and following all safety instructions.

- Being aware of the surroundings and potential hazards.

- Never working alone.

6. What are the ethical responsibilities of an NDE technician?

NDE technicians have a responsibility to perform their work ethically and to the best of their ability. Some of the most important ethical responsibilities of an NDE technician include:

- Maintaining confidentiality

- Being honest and accurate in their reporting

- Not falsifying or altering data

- Following all applicable safety regulations

7. What are some of the common challenges faced by NDE technicians?

NDE technicians face a number of common challenges, including:

- Interpreting complex data

- Working in difficult or dangerous environments

- Keeping up with the latest technology

- Balancing speed and accuracy

8. What are the career advancement opportunities for NDE technicians?

NDE technicians can advance their careers in a number of ways, including:

- Becoming a certified NDE technician

- Gaining experience in different industries

- Specializing in a particular NDE method

- Moving into a management or supervisory role

9. What is your experience with using NDE to inspect composite materials?

Composite materials are becoming increasingly common in a variety of industries, and NDE is an essential tool for inspecting these materials. I have experience using a variety of NDE methods to inspect composite materials, including ultrasonic testing, radiographic testing, and thermography.

- Ultrasonic testing is a non-destructive testing method that uses sound waves to detect and characterize defects in materials.

- Radiographic testing is a non-destructive testing method that uses X-rays or gamma rays to detect and characterize defects in materials.

- Thermography is a non-destructive testing method that uses infrared cameras to detect and characterize defects in materials.

10. What is your experience with using NDE to inspect welds?

Welds are critical components in many structures and machines, and NDE is an essential tool for inspecting welds to ensure their integrity. I have experience using a variety of NDE methods to inspect welds, including ultrasonic testing, radiographic testing, and magnetic particle testing.

- Ultrasonic testing is a non-destructive testing method that uses sound waves to detect and characterize defects in materials.

- Radiographic testing is a non-destructive testing method that uses X-rays or gamma rays to detect and characterize defects in materials.

- Magnetic particle testing is a non-destructive testing method that uses magnetic particles to detect and characterize defects in materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Non-Destructive Evaluation Technician (NDE Technician).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Non-Destructive Evaluation Technician (NDE Technician)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Non-Destructive Evaluation Technician (NDE Technician)

Non-Destructive Evaluation (NDE) Technicians play a crucial role in ensuring the integrity and safety of equipment and structures. Their primary responsibilities include:

1. Performing Nondestructive Testing (NDT) Examinations

NDE Technicians use specialized techniques and equipment to inspect materials and components without causing damage. They employ methods such as ultrasonic testing, radiographic testing, magnetic particle testing, and eddy current testing to detect and evaluate various defects, including cracks, corrosion, and material flaws.

- Prepare and conduct NDT examinations based on industry standards and specifications

- Operate and calibrate testing equipment to ensure accurate and reliable results

2. Data Analysis and Reporting

NDE Technicians analyze the data collected during NDT examinations to identify and interpret defects or anomalies. They prepare detailed reports that document findings, conclusions, and recommendations for further action, such as repairs or additional inspections.

- Interpret NDT data and identify potential defects or material weaknesses

- Write clear and concise reports that summarize findings and make recommendations

3. Ensuring Compliance and Quality Control

NDE Technicians ensure that NDT examinations are conducted in accordance with applicable standards and regulations. They maintain quality control measures to ensure the accuracy and reliability of test results. They also actively participate in quality improvement initiatives to enhance the overall effectiveness of NDT processes.

- Follow established protocols and procedures to ensure compliance with industry standards

- Maintain and calibrate equipment to achieve high levels of accuracy and reliability

4. Training and Communication

NDE Technicians may provide training to other technicians or stakeholders on NDT techniques and safety protocols. They effectively communicate findings and recommendations to engineers, maintenance personnel, and managers to facilitate decision-making and ensure the safe operation of equipment and structures.

- Train new technicians and provide guidance to ensure proper NDT practices

- Communicate inspection results and recommendations clearly and effectively to various stakeholders

Interview Preparation Tips for Non-Destructive Evaluation (NDE) Technicians

To ace an interview for an NDE Technician position, it is essential to be well-prepared. Consider the following tips and strategies:

1. Research the Company and Industry

Research the company you are applying for and the industry in which they operate. This will demonstrate your interest in the role and show that you have a good understanding of the context in which you will be working. Look for information about the company’s products, services, industry trends, and any specific challenges they may be facing.

2. Review Job Responsibilities and Requirements

Carefully review the job description and identify the key responsibilities and qualifications. Make a list of your skills and experience that align with each requirement. Highlight any relevant experience or projects that showcase your abilities in the following areas:

- Non-Destructive Testing (NDT) techniques (e.g., ultrasonic, radiographic, magnetic particle, eddy current)

- Data analysis and interpretation

- Report writing and communication

- Quality control and compliance

3. Practice Answering Common Interview Questions

Prepare for common interview questions by practicing your answers in advance. Research suggested responses and consider using the STAR method (Situation, Task, Action, Result) to structure your answers. Some common questions include:

- Tell us about your experience with Non-Destructive Testing (NDT) and any specialized techniques you have mastered.

- Describe a time when you identified a critical defect using NDT and how you communicated your findings to relevant stakeholders.

- Explain how you maintain quality control and ensure the accuracy of your NDT examinations.

- How do you stay updated on the latest NDT technologies and advancements in the industry?

4. Showcase Your Enthusiasm and Passion

During the interview, show your enthusiasm and passion for Non-Destructive Evaluation. Express your interest in the industry and discuss your aspirations for contributing to the safety and reliability of equipment and structures. Explain how your skills and experience can benefit the company and the field.

5. Ask Informed Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest and understanding of the role and industry. This can leave a positive impression and show that you are engaged and genuinely interested in the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Non-Destructive Evaluation Technician (NDE Technician) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!