Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Non-Destructive Testing Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Non-Destructive Testing Inspector so you can tailor your answers to impress potential employers.

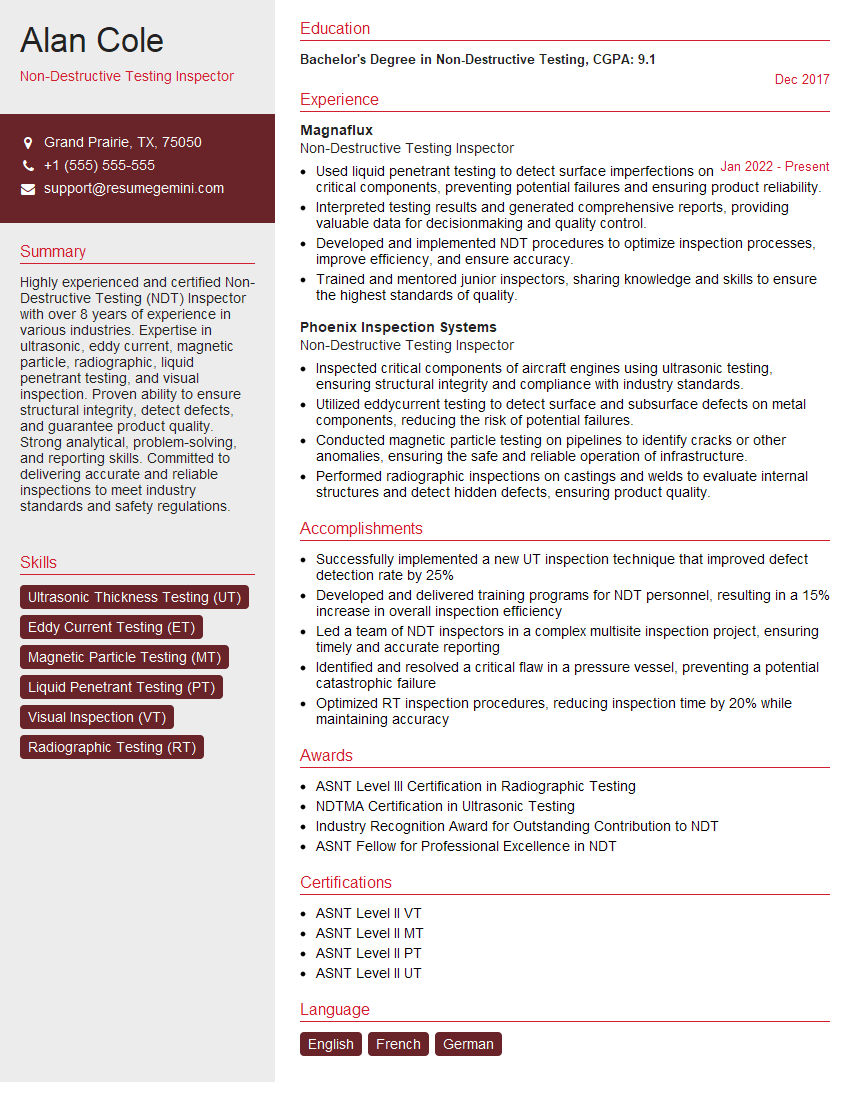

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Non-Destructive Testing Inspector

1. What are the different types of NDT methods and could you provide a brief overview of each one?

- Radiographic Testing (RT): Uses X-rays or gamma rays to detect internal flaws or defects.

- Ultrasonic Testing (UT): Utilizes high-frequency sound waves to identify surface and near-surface defects.

- Magnetic Particle Testing (MT): Detects surface and near-surface cracks or flaws using magnetic particles.

- Penetrant Testing (PT): Uses a liquid penetrant to reveal surface-breaking defects by capillary action.

- Eddy Current Testing (ET): Employs electromagnetic fields to sense variations in conductivity or permeability, detecting surface and subsurface defects.

2. How do you interpret and report NDT test results?

Understanding the Results

- Examine the test data and identify any indications or deviations from established standards.

- Analyze the shape, size, location, and signal strength of indications to determine their severity.

- Consider the material type, testing method, and other relevant factors affecting interpretation.

Reporting the Findings

- Prepare clear and concise reports that document the test results, including detected defects.

- Use industry-standard symbols and terminology to convey the location, type, and severity of defects.

3. Describe the safety precautions you observe during NDT exams.

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and protective suits.

- Follow radiation safety protocols when using radiation-based NDT methods.

- Ensure the testing area is well-ventilated, especially when using chemicals or fumes.

- Handle and transport NDT equipment carefully to avoid damage or injury.

- Properly store and dispose of hazardous materials, such as penetrant liquids or magnetic particles.

4. What is the ASNT Level II certification, and how does it benefit you as an NDT inspector?

- The ASNT Level II certification demonstrates a high level of competence and proficiency in performing NDT.

- It enhances credibility and recognition within the industry, demonstrating your expertise.

- Opens doors to more opportunities for career advancement and specialization.

- Provides a strong foundation for further professional growth and development.

5. Have you ever encountered any unusual or challenging defects during an inspection? How did you approach the situation?

Provide an example of a specific situation where you faced a difficult defect and describe the steps you took to resolve it.

- Describe the nature of the defect and the challenges it presented.

- Explain the approach you took to identify and analyze the defect.

- Discuss the methods or techniques you used to evaluate the severity and potential impact.

- Outline the actions you recommended or took to address the defect.

6. What is the difference between a discontinuity and a defect?

- Discontinuity: Any interruption in the normal material structure, such as a crack, void, or inclusion.

- Defect: A discontinuity that impairs the intended function or service life of the material.

7. Explain the concept of sensitivity and resolution in NDT.

- Sensitivity: The ability of an NDT method to detect small defects.

- Resolution: The ability of an NDT method to distinguish between closely spaced defects.

8. What is the role of calibration in NDT?

- Ensures the accuracy and reliability of NDT equipment and techniques.

- Verifies that the equipment is functioning within specified tolerances.

- Provides traceable measurements to maintain consistency and repeatability.

9. Describe the different types of NDT standards and their importance.

- ASTM Standards: Developed by the American Society for Testing and Materials, widely used for NDT methods and procedures.

- ASME Codes: Established by the American Society of Mechanical Engineers, provide rules and guidelines for NDT in specific industries.

- ISO Standards: International standards developed by the International Organization for Standardization, applicable globally.

10. How do you stay updated with the latest advancements in NDT technologies and techniques?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Participate in online forums and discussion groups.

- Pursue continuing education and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Non-Destructive Testing Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Non-Destructive Testing Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Non-Destructive Inspection Techniques

In this role, you will be responsible for conducting non-destructive testing (NDT) on various materials and components using advanced techniques. NDT methods allow for the evaluation of materials without causing damage, ensuring the safety and integrity of the inspected items.

- Employ a variety of NDT methods, including radiographic testing, ultrasonic testing, magnetic particle testing, and penetrant testing.

- Operate specialized NDT equipment and machinery to perform inspections efficiently and accurately.

2. Inspection Planning and Execution

Effective planning and execution of inspections are essential for successful NDT. You will be involved in:

- Reviewing engineering drawings, specifications, and inspection procedures to determine the appropriate NDT methods and techniques for the job.

- Preparing work areas, setting up equipment, and conducting inspections according to established standards and procedures.

3. Data Analysis and Reporting

The ability to analyze NDT data and present findings effectively is crucial. You will be responsible for:

- Interpreting NDT results and identifying any defects or anomalies in materials or components.

- Preparing detailed inspection reports that accurately document the findings and provide recommendations for corrective actions.

4. Collaboration and Communication

Effective collaboration and communication are essential in this role. You will work closely with engineers, technicians, and other stakeholders to ensure clear understanding of inspection results and recommendations.

- Collaborate with project engineers and technicians to determine inspection requirements and ensure adherence to specifications.

- Communicate inspection findings clearly and effectively to supervisors, clients, and other interested parties.

Interview Tips

To ace your interview for a Non-Destructive Testing Inspector position, it’s crucial to prepare thoroughly and demonstrate your knowledge, skills, and enthusiasm for the field.

1. Research the Company and Industry

Before the interview, take the time to research the company and the industry. Learn about their mission, values, and recent projects. Understanding the company’s goals and the industry’s trends will enable you to tailor your answers to the specific needs of the organization.

- Visit the company’s website and LinkedIn page to gather information about their work and culture.

- Stay up-to-date on industry news and trends by reading industry publications and attending webinars.

2. Highlight Your NDT Expertise

Emphasize your knowledge and experience in non-destructive testing techniques. Showcase your proficiency in using various NDT equipment and the ability to interpret and analyze results accurately.

- Provide specific examples of your involvement in successful NDT projects and the impact of your work.

- Quantify your accomplishments whenever possible, using metrics such as the number of inspections conducted or defects identified.

3. Demonstrate Your Communication Skills

Effective communication is vital in this role. During the interview, highlight your ability to communicate technical information clearly and concisely to both technical and non-technical audiences.

- Describe your experience in preparing inspection reports and presenting findings to clients and stakeholders.

- Provide examples of how you have successfully resolved communication challenges or misunderstandings in previous roles.

4. Show Your Enthusiasm for NDT

The interview is an opportunity to convey your passion for non-destructive testing. Express your interest in the industry, your commitment to safety and quality, and your desire to contribute to the field.

- Share your motivations for pursuing a career in NDT and your goals for professional development.

- Ask thoughtful questions about the company’s NDT practices and the industry’s future to demonstrate your engagement.

5. Prepare for Common Interview Questions

Familiarize yourself with common interview questions and prepare your responses in advance. This will help you answer questions confidently and effectively.

- Why are you interested in this position?

- Can you describe your experience with non-destructive testing techniques?

- How do you ensure the accuracy and reliability of your inspections?

- What are the ethical considerations in NDT?

- How do you stay up-to-date with advancements in the field?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Non-Destructive Testing Inspector role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.