Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Non Destructive Testing Under Water Welder (NDT U/W Welder) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

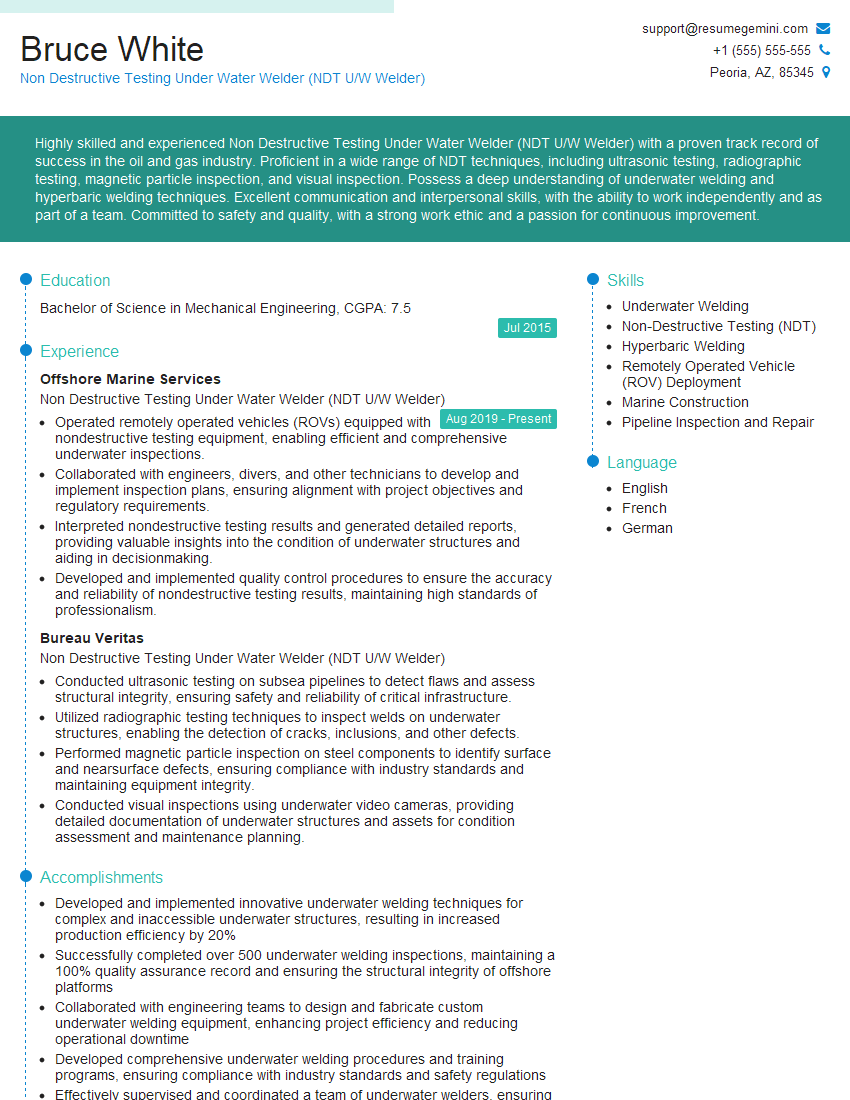

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Non Destructive Testing Under Water Welder (NDT U/W Welder)

1. Describe the steps involved in the visual examination of an underwater weld?

The visual examination of an underwater weld involves the following steps:

- Preparation: Before the examination, the weld area must be cleaned and prepared to ensure a clear view.

- Equipment setup: The appropriate equipment, such as a camera, lights, and viewing aids, are set up to provide a clear view of the weld.

- Examination: The weld is visually inspected for any surface defects or irregularities, such as cracks, porosity, or lack of fusion.

- Documentation: The findings of the examination are recorded and documented for future reference.

2. What are the advantages and disadvantages of using ultrasonic testing for underwater weld inspection?

Advantages:

- Ultrasonic testing provides high-resolution images of the weld, allowing for the detection of small defects.

- It is a non-destructive method, which means that it does not damage the weld being inspected.

- Ultrasonic testing can be used to inspect welds in a variety of environments, including underwater.

Disadvantages:

- Ultrasonic testing can be time-consuming, especially for large welds.

- It requires specialized equipment and trained personnel to perform.

- Ultrasonic testing can be affected by the presence of noise and interference in the water.

3. Explain the principle behind radiographic testing and how it is used in underwater weld inspection.

Radiographic testing uses high-energy radiation to penetrate the weld and create an image of the internal structure. The image is then analyzed for any defects or irregularities.

In underwater weld inspection, radiographic testing is typically performed using a portable X-ray or gamma ray source. The source is placed on one side of the weld, and a detector is placed on the other side. The radiation passes through the weld and creates an image on the detector.

4. What are the different types of underwater welding processes and their applications?

The different types of underwater welding processes include:

- Stick welding: This is the most common type of underwater welding, and it is used for a wide variety of applications.

- MIG welding: This process uses a continuously fed wire electrode, and it is typically used for welding thin metals.

- TIG welding: This process uses a non-consumable tungsten electrode, and it is typically used for welding thicker metals.

- Hyperbaric welding: This process is performed in a pressurized chamber, which allows the welder to work in a dry environment.

5. Describe the safety precautions that must be taken when performing underwater welding.

The following safety precautions must be taken when performing underwater welding:

- The welder must be properly trained and certified.

- The welding equipment must be in good working order and properly maintained.

- The welding area must be properly ventilated.

- The welder must wear appropriate protective clothing and gear.

- A safety observer must be present during all underwater welding operations.

6. What are the common challenges faced during underwater welding and how can they be overcome?

The common challenges faced during underwater welding include:

- Reduced visibility: The water can make it difficult to see the weld area clearly.

- Limited access: The welder may have limited access to the weld area due to the presence of equipment or other obstacles.

- Water pressure: The water pressure can make it difficult to manipulate the welding equipment.

- Cold temperatures: The water can be cold, which can make it difficult for the welder to work.

These challenges can be overcome by using specialized equipment and techniques, such as:

- Using a video camera to provide a clear view of the weld area.

- Using remote-controlled welding equipment to access difficult-to-reach areas.

- Using heated diving suits to keep the welder warm.

7. Describe the role of non-destructive testing in ensuring the quality of underwater welds.

Non-destructive testing (NDT) plays a critical role in ensuring the quality of underwater welds. NDT methods can be used to detect defects and irregularities in welds that may not be visible to the naked eye.

The different NDT methods used for underwater weld inspection include:

- Visual inspection

- Ultrasonic testing

- Radiographic testing

- Magnetic particle testing

8. Explain the importance of welder certification and how it is obtained.

Welder certification is a process that ensures that a welder has the skills and knowledge to perform underwater welding safely and effectively.

To obtain welder certification, a welder must:

- Complete a training program that covers the theory and practice of underwater welding.

- Pass a written examination.

- Pass a practical examination.

Welder certification is typically valid for a period of time, and it must be renewed regularly to ensure that the welder’s skills and knowledge are up to date.

9. What are the career advancement opportunities for NDT U/W Welders?

NDT U/W Welders can advance their careers by developing specialized skills and experience in a variety of areas, such as:

- Welding engineering: NDT U/W Welders can become welding engineers, who are responsible for designing and developing welding processes and equipment.

- Welding inspection: NDT U/W Welders can become welding inspectors, who are responsible for inspecting welds to ensure that they meet quality standards.

- Welding management: NDT U/W Welders can become welding managers, who are responsible for overseeing welding operations and ensuring that they are performed safely and efficiently.

10. How do you stay up-to-date on the latest developments in underwater welding technology?

I stay up-to-date on the latest developments in underwater welding technology by:

- Reading industry publications

- Attending conferences and workshops

- Networking with other professionals in the field

- Taking continuing education courses

By staying up-to-date on the latest developments, I am able to use the most advanced techniques and equipment to perform my job safely and efficiently.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Non Destructive Testing Under Water Welder (NDT U/W Welder).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Non Destructive Testing Under Water Welder (NDT U/W Welder)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An NDT U/W Welder is a highly specialized professional responsible for conducting non-destructive testing on underwater welding projects. Their primary duties include using advanced techniques to inspect and evaluate the integrity of underwater welds, ensuring they meet safety standards and quality requirements

1. Non-Destructive Testing

Conduct a wide range of non-destructive testing techniques, including visual inspection, ultrasonic testing, radiographic testing, magnetic particle testing, and liquid penetrant testing.

- Analyze test results to identify any defects or anomalies in underwater welds.

- Create detailed reports documenting the inspection findings and make recommendations for corrective actions.

2. Underwater Welding Inspection

Inspect underwater welds using specialized equipment, such as remotely operated vehicles (ROVs) and diving gear.

- Assess the quality of welds, including penetration, fusion, and surface finish.

- Identify potential defects, such as cracks, porosity, and undercuts.

3. Welding Equipment Maintenance and Repair

Maintain and repair welding equipment, including welding torches, power sources, and gas regulators.

- Troubleshoot equipment malfunctions and perform necessary repairs.

- Ensure that all equipment is properly calibrated and in good working order.

4. Safety and Regulations Compliance

Adhere to all safety regulations and guidelines related to underwater welding and non-destructive testing.

- Follow proper diving procedures and use appropriate safety gear.

- Maintain a clean and organized work area.

Interview Tips

Preparing thoroughly for an interview is crucial to increasing your chances of success. Here are some tips and hacks to help you ace the interview for a Non Destructive Testing Under Water Welder position.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and the expectations for the role.

- Visit the company’s website and read about their mission, vision, and services.

- Search for news articles or industry reports that mention the company.

- Look up the LinkedIn profiles of employees in similar roles to gain insights into their experiences and qualifications.

2. Highlight Your Skills and Experience

In your resume and during the interview, be sure to highlight your relevant skills and experience. Quantify your accomplishments whenever possible and provide specific examples of your work.

- Emphasize your proficiency in non-destructive testing techniques and your experience in underwater welding inspection.

- Showcase your ability to work independently and as part of a team.

- Provide examples of times you have successfully identified and resolved welding defects.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers beforehand. This will help you feel more confident and articulate during the actual interview.

- Example: Tell me about a time you faced a challenging welding inspection. How did you approach the situation and what was the outcome?

- Example: Describe your experience with using non-destructive testing equipment. What are the different techniques you are familiar with?

- Example: How do you stay up-to-date on the latest developments in underwater welding and non-destructive testing?

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure you dress professionally for the interview. Arrive on time, as punctuality demonstrates respect for the interviewer’s time.

- Choose business attire that is clean, pressed, and fits you well.

- Arrive at the interview location 10-15 minutes early to allow for any unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Non Destructive Testing Under Water Welder (NDT U/W Welder) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!