Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Non Destructive Testing Underwater Welder (NDT U/W Welder) interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Non Destructive Testing Underwater Welder (NDT U/W Welder) so you can tailor your answers to impress potential employers.

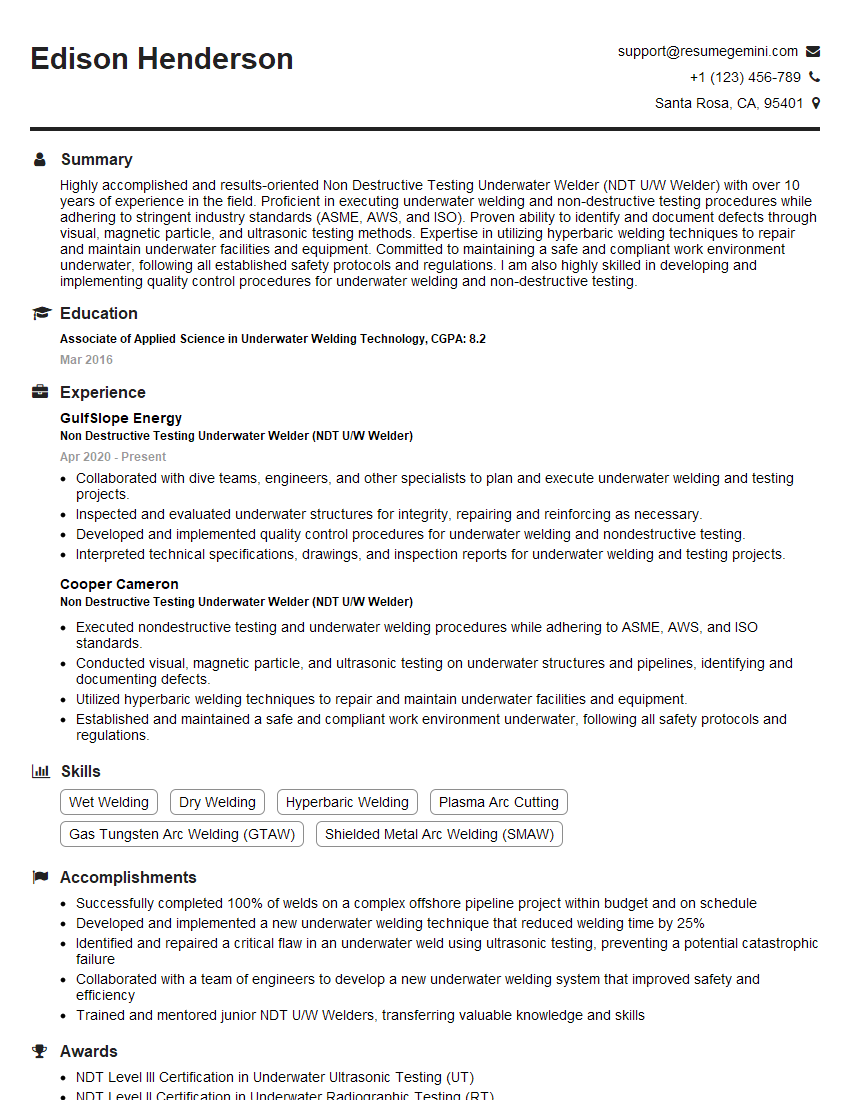

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Non Destructive Testing Underwater Welder (NDT U/W Welder)

1. What is the difference between MPI (Magnetic Particle Inspection) and DPI (Dye Penetrant Inspection)?

- MPI: A non-destructive testing method that detects surface and near-surface discontinuities in ferromagnetic materials.

- DPI: A non-destructive testing method that detects surface-breaking discontinuities in non-porous materials.

- MPI uses magnetic particles to find discontinuities, while DPI uses a penetrant and developer to find discontinuities.

- MPI is typically used on ferromagnetic materials, such as steel and iron, while DPI can be used on a variety of materials, including metals, ceramics, and plastics.

2. Describe the different types of ultrasonic testing (UT) probes and their applications

- Normal beam probes: Used for general-purpose testing and to detect defects in the near-surface region.

- Angle beam probes: Used to detect defects in the subsurface region.

- Phased array probes: Used to create complex ultrasonic beams that can be steered and focused.

- Immersion probes: Used for testing parts that are submerged in a liquid.

- Contact probes: Used for testing parts that are not submerged in a liquid.

3. What are the advantages and disadvantages of using radiographic testing (RT)?

Advantages

- Can be used to inspect a wide range of materials, including metals, plastics, and composites.

- Can detect both surface and subsurface defects

- Is a relatively inexpensive and portable method.

Disadvantages

- Can be harmful to personnel if not used properly.

- Can only be used on materials that are transparent to X-rays.

- Can be difficult to interpret results.

4. What are the different levels of certification for NDT personnel?

- Level I: Entry-level certification that allows personnel to perform basic NDT tasks.

- Level II: Intermediate-level certification that allows personnel to perform more complex NDT tasks.

- Level III: Advanced-level certification that allows personnel to supervise and train other NDT personnel.

5. What are the safety precautions that must be taken when performing NDT underwater?

- Wear appropriate safety gear, including a dry suit, gloves, and a helmet.

- Use a dive computer to monitor depth and time.

- Stay within the no-decompression limits.

- Avoid diving alone.

- Be aware of the hazards of cold water and decompression sickness.

6. What are the different types of weld defects that can be detected using NDT?

- Cracks: A separation of the metal that can occur in the weld metal, heat-affected zone, or base metal.

- Porosity: A cluster of voids or gas bubbles in the weld metal.

- Inclusions: Foreign particles that are trapped in the weld metal.

- Lack of fusion: A condition where the weld metal has not fully fused with the base metal.

- Undercut: A groove or notch that is formed at the edge of the weld.

7. How do you interpret the results of an NDT inspection?

- Start by identifying the type of defect that is present.

- Determine the size and location of the defect.

- Evaluate the severity of the defect.

- Make a recommendation for repair or replacement.

8. What are the ethical responsibilities of an NDT inspector?

- To report all defects accurately and impartially.

- To maintain confidentiality of the inspection results.

- To avoid conflicts of interest.

- To stay up-to-date on the latest NDT techniques.

- To promote the safe and ethical use of NDT.

9. What is your experience with using NDT equipment in the field?

- Describe the specific NDT equipment that you have used in the field.

- Provide examples of how you have used NDT equipment to solve problems or ensure the safety of a structure or product.

- Explain how you stay up-to-date on the latest NDT techniques.

10. What are your career goals?

- State your long-term career goals in the field of NDT.

- Explain how this position aligns with your career goals.

- Express your enthusiasm for the opportunity to contribute to the company’s success.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Non Destructive Testing Underwater Welder (NDT U/W Welder).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Non Destructive Testing Underwater Welder (NDT U/W Welder)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Non Destructive Testing Underwater Welders (NDT U/W Welders) are responsible for performing a wide range of non-destructive testing (NDT) techniques on underwater welded structures. These techniques are used to ensure the integrity and safety of underwater welded structures such as pipelines, offshore platforms, and ship hulls.

1. NDT Techniques

NDT U/W Welders are proficient in a variety of NDT techniques, including:

- Visual Inspection: Examining welded joints for surface defects such as cracks, porosity, and undercut.

- Magnetic Particle Inspection (MPI): Using magnetic fields to detect surface and near-surface cracks.

- Ultrasonic Testing (UT): Using sound waves to detect internal defects such as cracks, voids, and delaminations.

- Radiographic Testing (RT): Using X-rays or gamma rays to create images of internal defects.

- Eddy Current Testing (ECT): Using electromagnetic fields to detect surface and near-surface defects.

- Dye Penetrant Testing (DPT): Using fluorescent dyes to detect surface cracks.

2. Underwater Welding

NDT U/W Welders are also skilled in underwater welding. They use specialized equipment and techniques to weld underwater in a variety of environments, including offshore platforms, pipelines, and ship hulls.

- Wet Welding: Using shielded metal arc welding (SMAW) or gas tungsten arc welding (GTAW) in a wet environment.

- Dry Welding: Using hyperbaric welding chambers to create a dry environment for welding.

3. Safety and Regulations

NDT U/W Welders must adhere to strict safety regulations and guidelines. They must be trained in diving safety and underwater welding procedures.

- Following diving safety protocols

- Using specialized underwater welding equipment

- Adhering to welding codes and standards

4. Communication and Teamwork

NDT U/W Welders often work as part of a team. They must be able to communicate effectively with divers, engineers, and other team members.

- Communicating with divers using hand signals or underwater communication systems

- Working with engineers to interpret NDT results and recommend corrective actions

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips for NDT U/W Welder interviews:

1. Research the Company and Position

Take the time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and the specific skills and experience they’re looking for.

2. Practice Your Answers

Think about common interview questions and prepare your answers in advance. This will help you feel more confident and articulate during the interview. Consider using the STAR method to answer behavioral questions:

- Situation: Briefly describe the situation or task you were involved in.

- Task: Explain your role and responsibilities in the situation.

- Action: Describe the specific actions you took to address the situation or complete the task.

- Result: Quantify or otherwise describe the positive outcomes or results of your actions.

3. Highlight Your Skills and Experience

Be sure to emphasize your skills and experience that are relevant to the NDT U/W Welder position. Use specific examples to demonstrate your proficiency in NDT techniques, underwater welding, and safety procedures.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. Prepare questions about the company’s projects, safety culture, and opportunities for growth.

5. Follow Up

After the interview, send a thank-you note to the interviewer. This is an opportunity to reiterate your interest in the position and thank them for their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Non Destructive Testing Underwater Welder (NDT U/W Welder) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!