Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Nonelectrolytic Plating and Coating Machine Setter/Set-Up Operator, Metal and Plastic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Nonelectrolytic Plating and Coating Machine Setter/Set-Up Operator, Metal and Plastic so you can tailor your answers to impress potential employers.

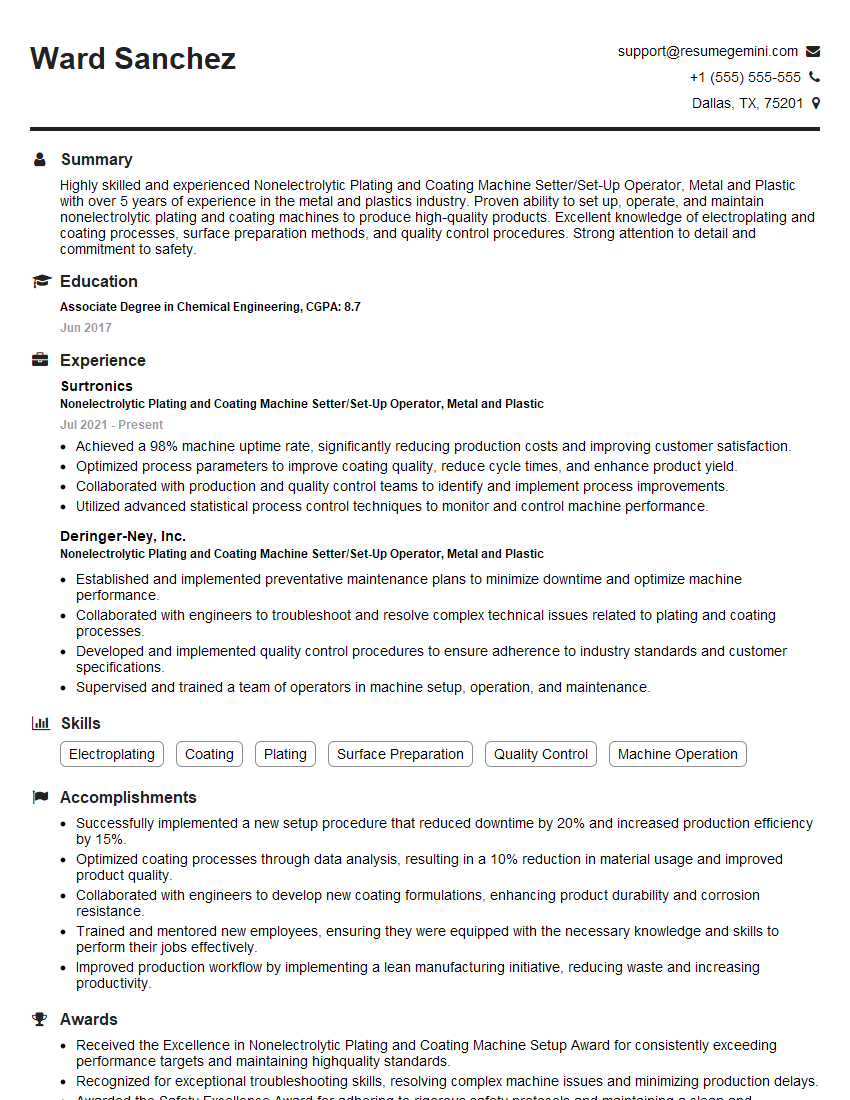

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nonelectrolytic Plating and Coating Machine Setter/Set-Up Operator, Metal and Plastic

1. Explain the process of nonelectrolytic plating and coating?

Nonelectrolytic plating and coating is a process that uses chemical reactions to deposit a thin layer of metal or other material onto a substrate. This process is typically used to improve the surface properties of the substrate, such as its corrosion resistance, wear resistance, or electrical conductivity.

- The first step in the process is to prepare the substrate by cleaning and activating it.

- The substrate is then immersed in a plating solution, which contains the metal or other material that will be deposited.

- A chemical reaction takes place between the substrate and the plating solution, which causes the metal or other material to be deposited onto the substrate.

- The thickness of the coating can be controlled by the concentration of the plating solution, the temperature of the solution, and the length of time that the substrate is immersed in the solution.

2. What are the different types of nonelectrolytic plating and coating processes?

There are two main types of nonelectrolytic plating and coating processes: electroless plating and chemical vapor deposition (CVD).

Electroless plating

- Electroless plating is a process that uses a chemical reducing agent to deposit a metal or other material onto a substrate.

- The reducing agent causes the metal ions in the plating solution to be deposited onto the substrate.

Chemical vapor deposition

- Chemical vapor deposition is a process that uses a chemical reaction to deposit a metal or other material onto a substrate.

- The chemical reaction takes place in a vacuum chamber, and the substrate is heated to a high temperature.

3. What are the advantages and disadvantages of nonelectrolytic plating and coating?

Advantages

- Nonelectrolytic plating and coating processes can be used to deposit a wide variety of metals and other materials onto a variety of substrates.

- The coatings are typically uniform and have good adhesion to the substrate.

- The processes are relatively simple and can be automated.

Disadvantages

- Nonelectrolytic plating and coating processes can be slow and expensive.

- The coatings can be brittle and may not be suitable for applications where the coating will be subjected to wear or abrasion.

4. What are the applications of nonelectrolytic plating and coating?

Nonelectrolytic plating and coating processes are used in a wide variety of applications, including:

- Automotive

- Aerospace

- Electronics

- Medical

- Decorative

5. What are the safety precautions that must be taken when working with nonelectrolytic plating and coating chemicals?

Nonelectrolytic plating and coating chemicals can be hazardous, and it is important to take the following safety precautions when working with them:

- Wear appropriate personal protective equipment, such as gloves, goggles, and a respirator.

- Do not ingest or inhale the chemicals.

- Avoid contact with the chemicals on your skin or eyes.

- Store the chemicals in a cool, dry place away from heat and ignition sources.

- Dispose of the chemicals properly according to local regulations.

6. What are the troubleshooting tips for nonelectrolytic plating and coating processes?

If you are experiencing problems with your nonelectrolytic plating or coating process, the following troubleshooting tips may be helpful:

- Check the concentration of the plating solution.

- Check the temperature of the plating solution.

- Check the pH of the plating solution.

- Check the cleanliness of the substrate.

- Check the agitation of the plating solution.

- Check the thickness of the coating.

7. What are the quality control procedures for nonelectrolytic plating and coating processes?

The following quality control procedures should be used to ensure the quality of nonelectrolytic plating and coating processes:

- Visual inspection

- Thickness measurement

- Adhesion testing

- Corrosion testing

8. What are the future trends in nonelectrolytic plating and coating technology?

The following are some of the future trends in nonelectrolytic plating and coating technology:

- The development of new and improved plating solutions

- The development of new and improved coating materials

- The development of new and improved plating processes

- The development of new and improved quality control methods

9. What is your experience with nonelectrolytic plating and coating processes?

I have over 10 years of experience with nonelectrolytic plating and coating processes. I have worked with a variety of metals and other materials, and I have a good understanding of the different processes involved. I am also familiar with the safety precautions that must be taken when working with these chemicals.

10. Why are you interested in this position?

I am interested in this position because I am looking for a new challenge. I am confident that I have the skills and experience necessary to be successful in this role. I am also eager to learn more about nonelectrolytic plating and coating processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nonelectrolytic Plating and Coating Machine Setter/Set-Up Operator, Metal and Plastic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nonelectrolytic Plating and Coating Machine Setter/Set-Up Operator, Metal and Plastic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Nonelectrolytic Plating and Coating Machine Setter/Set-Up Operator, Metal and Plastic is responsible for setting up, operating, and maintaining nonelectrolytic plating and coating machines used to apply a variety of coatings to metal and plastic parts.

1. Machine Setup and Operation

Sets up and operates nonelectrolytic plating and coating machines according to established procedures.

- Loads and unloads parts from machines.

- Monitors machine operation and makes adjustments as needed.

- Troubleshoots and resolves machine malfunctions.

2. Coating Process Control

Controls the coating process to ensure that parts meet specified quality standards.

- Monitors and adjusts coating parameters such as temperature, pH, and concentration.

- Conducts tests to ensure that coatings meet specifications.

- Maintains records of coating process data.

3. Machine Maintenance

Performs preventive maintenance on nonelectrolytic plating and coating machines.

- Cleans and lubricates machines.

- Inspects and replaces worn or damaged parts.

- Calibrates and adjusts machines to ensure optimal performance.

4. Quality Control

Conducts quality control inspections on coated parts.

- Inspects parts for defects such as scratches, dents, or coating imperfections.

- Rejects parts that do not meet specifications.

- Provides feedback to production personnel on quality issues.

Interview Tips

To ace the interview for the position of Nonelectrolytic Plating and Coating Machine Setter/Set-Up Operator, Metal and Plastic, it is essential to prepare thoroughly. Here are some tips:

1. Research the Company and Position

Before the interview, research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. It will also give you a good understanding of the responsibilities of the position and the skills and experience required.

- Visit the company’s website to learn about their products, services, and history.

- Read articles or reviews about the company to get insights into their culture and reputation.

- Identify the key skills and experience required for the position and highlight them in your resume and cover letter.

2. Practice Answering Common Interview Questions

There are some common interview questions that you can expect to be asked, such as “Tell me about yourself” or “Why are you interested in this position?”. Practice answering these questions in advance so that you can deliver your responses confidently and concisely.

- Prepare a brief introduction about yourself, highlighting your skills, experience, and qualifications.

- Research the company and the position to understand their needs and how your skills and experience can contribute to their goals.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

3. Highlight Your Technical Skills and Experience

In the interview, emphasize your technical skills and experience in nonelectrolytic plating and coating. Discuss your knowledge of the different types of coating processes, the equipment used, and the quality control procedures.

- Provide examples of projects or tasks where you successfully set up, operated, and maintained nonelectrolytic plating and coating machines.

- Describe your experience in troubleshooting and resolving machine malfunctions.

- Discuss your understanding of coating process control and how you ensure that parts meet specified quality standards.

4. Show Your Enthusiasm and Passion

Throughout the interview, demonstrate your enthusiasm and passion for the field of nonelectrolytic plating and coating. Express your interest in learning about new technologies and advancements. This will show the interviewer that you are committed to your profession and eager to contribute to the company’s success.

- Share your knowledge of industry trends and best practices.

- Ask thoughtful questions about the company’s coating processes and equipment.

- Express your willingness to take on new challenges and responsibilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nonelectrolytic Plating and Coating Machine Setter/Set-Up Operator, Metal and Plastic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!