Feeling lost in a sea of interview questions? Landed that dream interview for Nonferrous Metal Precision Pattern and Die Caster but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Nonferrous Metal Precision Pattern and Die Caster interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

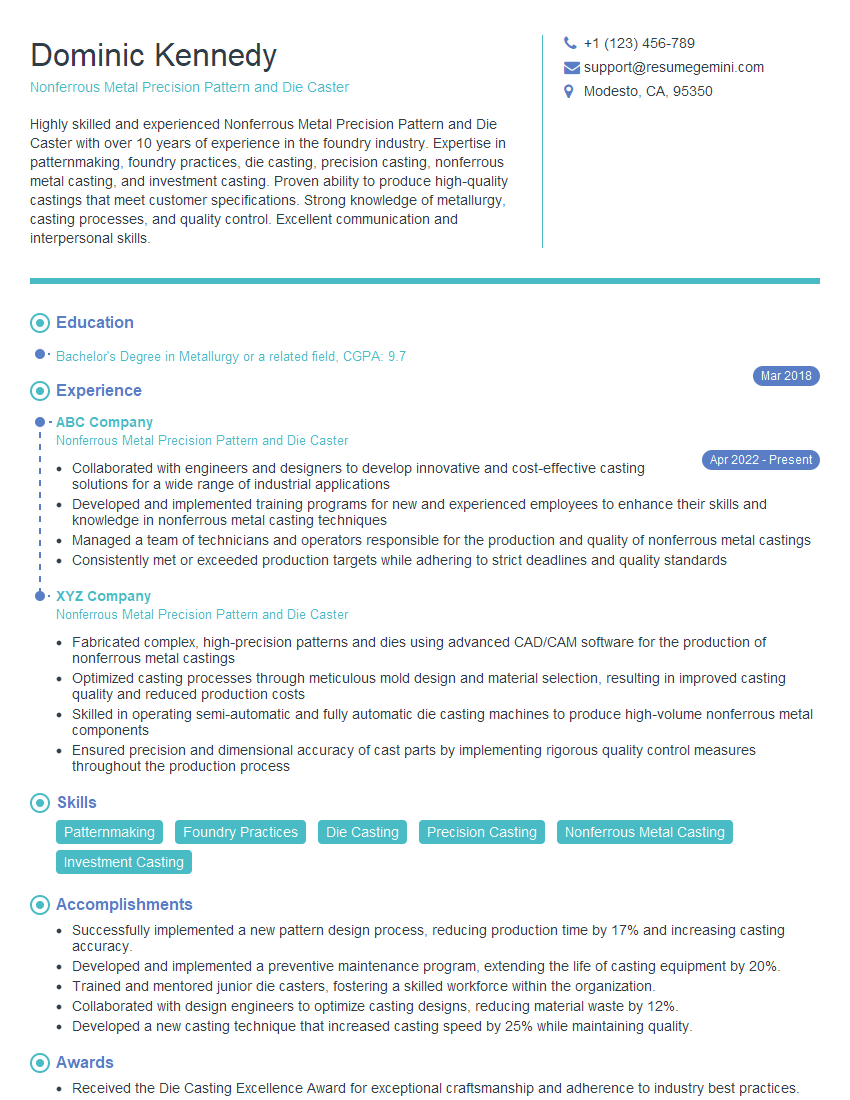

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nonferrous Metal Precision Pattern and Die Caster

1. Explain the process of precision pattern making for nonferrous metal casting?

In precision pattern making for nonferrous metal casting, high-precision patterns are created using advanced techniques to produce high-quality castings. The process involves:

- Design and Engineering: Creating the pattern design based on the desired casting specifications.

- Pattern Material Selection: Choosing the appropriate pattern material, such as epoxy resin, wax, or metal, based on the casting process and precision requirements.

- Pattern Creation: Using CNC machining, 3D printing, or other precision techniques to create the pattern with accurate dimensions and surface finishes.

- Pattern Verification: Inspecting and verifying the pattern to ensure it meets the required tolerances and specifications.

2. Describe the different types of die casting processes used for nonferrous metals?

- Gravity Die Casting: Molten metal is poured into a mold under the force of gravity, filling the mold cavity.

- Pressure Die Casting: Molten metal is injected into a mold under high pressure, ensuring complete filling and high dimensional accuracy.

- Cold Chamber Die Casting: Molten metal is manually poured into a cold chamber and then injected into the mold under pressure.

- Hot Chamber Die Casting: Molten metal is held in a heated chamber and forced into the mold under pressure.

3. What are the factors to consider when selecting the appropriate nonferrous metal for die casting?

Factors to consider when selecting the appropriate nonferrous metal for die casting include:

- Mechanical Properties: Strength, hardness, ductility, and impact resistance.

- Corrosion Resistance: Resistance to environmental degradation, such as oxidation and chemical attack.

- Castability: Ease of filling the mold and achieving good surface quality.

- Cost: Availability and affordability of the metal.

- Application: The intended use and performance requirements of the casting.

4. How do you ensure dimensional accuracy and surface quality in die castings?

To ensure dimensional accuracy and surface quality, the following steps are taken:

- Precision Pattern: Using high-precision patterns ensures accurate transfer of dimensions to the casting.

- Mold Design and Maintenance: Designing and maintaining molds with proper tolerances and surface finishes is crucial.

- Process Control: Monitoring and controlling casting parameters, such as temperature, pressure, and injection speed, ensures consistency.

- Inspection and Finishing: Inspecting the castings for defects and applying post-processing techniques, such as trimming, grinding, or polishing, improves dimensional accuracy and surface quality.

5. Explain the safety precautions and regulations that must be followed in a nonferrous metal precision pattern and die casting facility?

- Personal Protective Equipment (PPE): Wearing appropriate PPE, such as safety glasses, gloves, and protective clothing, is essential.

- Machine Safety: Following established safety procedures for operating machinery, including lockout/tagout and proper guarding.

- Material Handling: Handling molten metal and heavy materials with care to prevent accidents.

- Ventilation: Ensuring adequate ventilation to remove fumes and dust generated during the casting process.

- Training and Supervision: Providing training and supervision to employees on safety protocols and emergency procedures.

6. What are the industry trends and advancements in nonferrous metal precision pattern and die casting?

- Additive Manufacturing: Using 3D printing to create complex patterns, reducing lead times and improving design flexibility.

- Simulation and Modeling: Employing computer simulation to optimize mold design, casting parameters, and predict casting performance.

- Automation and Robotics: Integrating automation and robotics to enhance efficiency, productivity, and safety.

- Sustainable Practices: Implementing environmentally friendly processes to reduce waste and energy consumption.

- Advanced Materials: Developing new nonferrous metals and alloys with improved properties for specific applications.

7. Describe your experience in troubleshooting and problem-solving during nonferrous metal precision pattern and die casting operations?

In troubleshooting and problem-solving, I follow these steps:

- Identify the issue: Clearly define the problem and its impact.

- Analyze potential causes: Consider various factors that may contribute to the issue, such as pattern accuracy, mold design, or casting parameters.

- Investigate and test: Conduct experiments or tests to isolate the root cause.

- Develop solutions: Propose and implement solutions to resolve the issue and improve the casting process.

- Monitor and evaluate: Track the effectiveness of the solutions and make necessary adjustments to ensure long-term improvement.

8. Explain the significance of quality control and inspection in nonferrous metal precision pattern and die casting?

Quality control and inspection are critical to ensure the production of high-quality castings. They involve:

- Pattern Verification: Inspecting patterns for accuracy, surface finish, and dimensional compliance.

- Mold Validation: Verifying mold dimensions, surface quality, and operation before casting.

- Casting Inspection: Examining castings for defects, such as porosity, cracks, and dimensional variations.

- Process Monitoring: Tracking casting parameters and identifying any deviations that may affect quality.

- Non-Destructive Testing: Using methods like ultrasonic testing to detect internal defects without damaging the casting.

9. What are the key performance indicators (KPIs) used to measure the effectiveness of a nonferrous metal precision pattern and die casting operation?

- Product Quality: Yield, defect rate, and customer satisfaction.

- Efficiency: Production rate, lead times, and utilization of equipment.

- Cost: Material costs, labor costs, and overhead expenses.

- Safety: Accident rates and compliance with safety regulations.

- Innovation: Development of new products, processes, and technologies.

10. How do you stay updated with the latest advancements and best practices in nonferrous metal precision pattern and die casting?

I stay updated with advancements and best practices through:

- Industry Conferences and Exhibitions: Attending events to learn about new technologies and network with experts.

- Technical Publications: Reading trade journals, research papers, and technical articles.

- Online Resources: Utilizing online forums, industry websites, and social media platforms.

- Professional Development: Pursuing certifications, training programs, and workshops to enhance my knowledge and skills.

- Internal Training: Participating in company-organized training sessions to share knowledge and improve best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nonferrous Metal Precision Pattern and Die Caster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nonferrous Metal Precision Pattern and Die Caster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nonferrous Metal Precision Pattern and Die Casters are responsible for manufacturing precision parts and components for a wide range of industries, including aerospace, automotive, and electronics.

1. Design and manufacture patterns

Nonferrous Metal Precision Pattern and Die Casters work closely with engineers to design and manufacture patterns, which are used to create molds for casting metal parts.

- Use computer-aided design (CAD) software to create 3D models of patterns.

- Program CNC machines to cut patterns from metal or plastic.

- Inspect patterns to ensure that they meet specifications.

2. Build and maintain dies

Nonferrous Metal Precision Pattern and Die Casters build and maintain dies, which are used to cast metal parts.

- Assemble dies according to engineering drawings.

- Inspect dies to ensure that they are in good working order.

- Repair or replace worn or damaged dies.

3. Cast metal parts

Nonferrous Metal Precision Pattern and Die Casters cast metal parts using a variety of techniques, including sand casting, investment casting, and die casting.

- Prepare molds for casting.

- Melt metal and pour it into molds.

- Remove castings from molds.

- Inspect castings to ensure that they meet specifications.

4. Machine and finish castings

Nonferrous Metal Precision Pattern and Die Casters machine and finish castings to remove burrs and other imperfections.

- Use CNC machines to mill, drill, and grind castings.

- Inspect castings to ensure that they meet specifications.

- Apply finishes to castings, such as plating or painting.

Interview Tips

To ace an interview for a Nonferrous Metal Precision Pattern and Die Caster position, it is important to be prepared. Here are a few tips:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website.

- Read articles about the company in trade publications.

- Talk to people who work at the company.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions ahead of time so that you can deliver your responses confidently.

- Use the STAR method to answer interview questions.

- Situation: Describe the situation or task that you were faced with.

- Task: Explain the specific task that you were responsible for.

- Action: Describe the specific actions that you took to complete the task.

- Result: Explain the positive results of your actions.

3. Be prepared to talk about your skills and experience

The interviewer will want to know about your skills and experience, so be prepared to talk about your qualifications. Highlight your experience in designing and manufacturing patterns, building and maintaining dies, casting metal parts, and machining and finishing castings.

4. Dress professionally and arrive on time

Dress professionally for your interview and arrive on time. This will show the interviewer that you are serious about the position and that you respect their time.

5. Be confident and enthusiastic

Be confident and enthusiastic during your interview. This will show the interviewer that you are excited about the position and that you are a positive and motivated individual.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nonferrous Metal Precision Pattern and Die Caster interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!