Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Novelty Candy Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

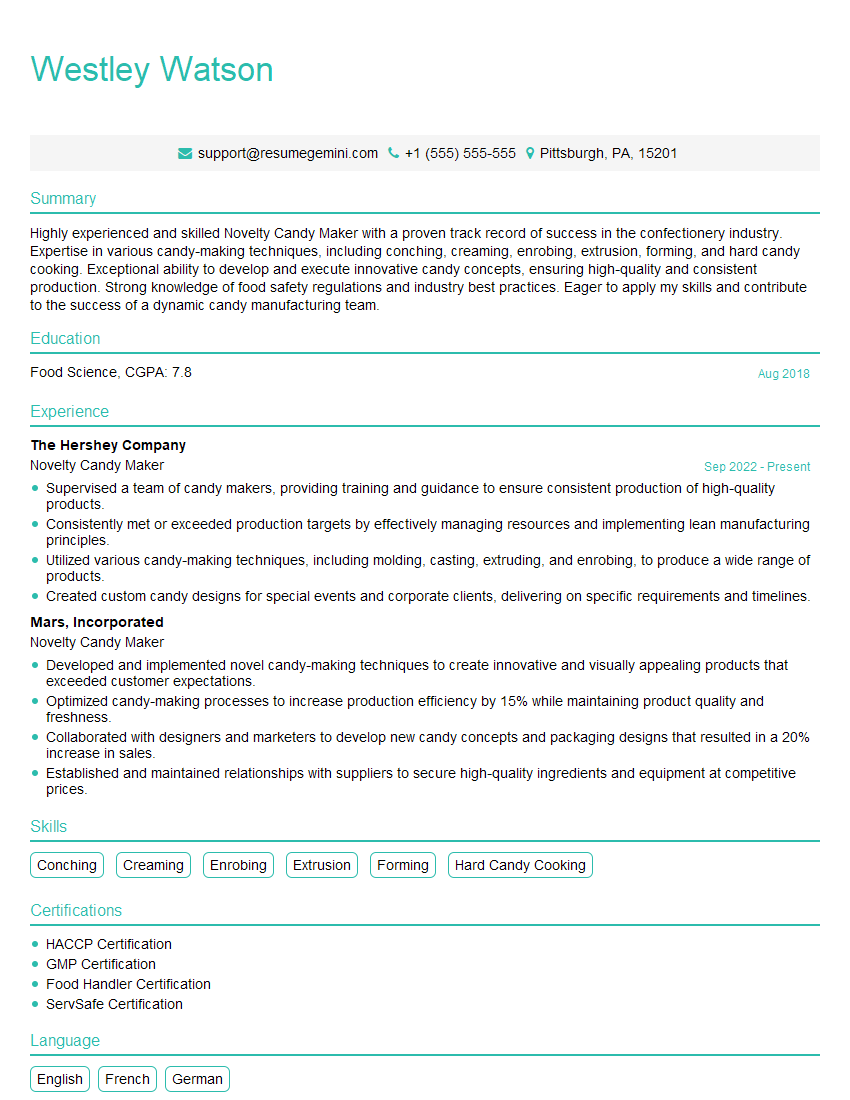

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Novelty Candy Maker

1. What are the key ingredients used in making novelty candies and how do they contribute to the final product?

As a seasoned Novelty Candy Maker, I am well-versed in the intricacies of candy-making. The foundation of novelty candies lies in a blend of sugar, corn syrup, water, and flavorings. Sugar provides the sweetness and structure, while corn syrup prevents crystallization, resulting in a smooth and chewy texture. Water dissolves the sugar and helps achieve the desired consistency. Flavorings, both natural and artificial, impart the distinctive taste and aroma to each candy creation.

2. Describe the different types of molding techniques used in novelty candy production and how the choice of technique affects the final product.

Molding is a crucial aspect of novelty candy making, and I am proficient in various techniques. Pour molding involves pouring molten candy into molds, creating solid pieces with intricate shapes and designs. Press molding utilizes two molds to press the candy into shape, achieving detailed impressions. Rotary molding is employed for high-volume production, where molten candy is poured into rotating molds to form continuous shapes. The choice of technique depends on the desired shape, size, and complexity of the candy.

Mold Lubrication

- Mold lubrication is essential to prevent sticking and ensure easy candy release.

- I typically use vegetable oils or confectioner’s glaze to lightly coat the molds.

- Proper lubrication allows for clean and efficient candy production.

3. Explain the process of tempering chocolate and its importance in novelty candy making.

Tempering chocolate is a delicate art that I have mastered. It involves heating and cooling chocolate under controlled conditions to achieve a stable crystalline structure. Proper tempering results in a glossy finish, a crisp snap, and resistance to melting at room temperature. Conversely, untempered chocolate can appear dull, soft, and have poor shelf life. I meticulously follow the tempering process to ensure the highest quality and appeal of my chocolate creations.

4. What are the common defects in novelty candies and how can they be prevented or corrected?

As a meticulous Novelty Candy Maker, I am vigilant in identifying and addressing potential defects in my creations. Common defects include crystallization, stickiness, discoloration, and breakage. Crystallization can be prevented by controlling sugar concentration and using anti-crystallizing agents. Stickiness can be reduced by adjusting the moisture content and using appropriate drying techniques. Discoloration can be avoided by using high-quality ingredients and protecting candies from light and heat. Breakage can be minimized by handling candies carefully and using proper packaging.

5. Describe your experience in creating and developing new novelty candy products.

Innovation is a driving force in my work as a Novelty Candy Maker. I am passionate about conceiving and developing new candy creations that delight consumers. My approach involves exploring unique flavor combinations, experimenting with different textures, and incorporating novel ingredients. I conduct thorough research, consult with food scientists, and leverage my creativity to bring innovative candy concepts to life.

6. What are the safety and sanitation guidelines that must be strictly followed in a novelty candy production facility?

Adhering to stringent safety and sanitation guidelines is paramount in my role as a Novelty Candy Maker. I am committed to maintaining a clean and hygienic work environment to ensure the safety and integrity of our candy products. I follow established protocols for proper food handling, equipment sanitization, and personal hygiene. I also undergo regular food safety training to stay updated on the latest industry regulations and best practices.

7. How do you maintain the quality and consistency of your novelty candies throughout the production process?

Maintaining exceptional quality and consistency is a cornerstone of my approach as a Novelty Candy Maker. I implement robust quality control measures throughout the production process. This includes meticulous ingredient selection, precise recipe formulation, and adherence to standardized production procedures. I regularly conduct in-process inspections and sensory evaluations to ensure that my candies meet the highest standards. My unwavering commitment to quality guarantees that every candy I create is a testament to my dedication to excellence.

8. What techniques do you use to package and store novelty candies to maintain their freshness and prevent spoilage?

Preserving the freshness and preventing spoilage of my novelty candies is a critical aspect of my role as a Candy Maker. I employ a combination of effective packaging and storage techniques to ensure that my creations reach consumers in pristine condition. My packaging materials are carefully selected to maintain the candies’ integrity and protect them from external elements. I also utilize controlled storage environments, employing appropriate temperature and humidity levels to prevent spoilage and extend shelf life. By meticulously following these protocols, I guarantee that my candies retain their optimal taste, texture, and appearance.

9. Describe your experience in working with a team to produce large volumes of novelty candies efficiently.

Collaboration and teamwork are essential in my role as a Novelty Candy Maker, especially when producing large volumes of candies efficiently. I am an effective team player, adept at coordinating with colleagues to streamline production processes. I actively participate in planning and organizing tasks, ensuring that each team member’s responsibilities are clear and aligned with the overall production goals. Through open communication and a shared commitment to quality, I foster a positive and productive work environment, enabling us to meet high production targets without compromising the integrity of our products.

10. What are your thoughts on the latest trends in novelty candy making and how do you incorporate them into your work?

As a forward-thinking Novelty Candy Maker, I am constantly monitoring the latest trends in the industry. I believe that staying abreast of these trends is essential for creating innovative and exciting candies that meet the evolving tastes of consumers. I actively seek out new techniques, flavors, and ingredients, experimenting with them to develop unique and memorable candy creations. By incorporating these trends into my work, I push the boundaries of candy making and offer customers a delightful and contemporary candy experience.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Novelty Candy Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Novelty Candy Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Novelty Candy Makers are responsible for producing and decorating various confectionery products. Their job involves a combination of technical skills, creativity, and attention to detail to ensure that the candies meet quality standards and customer expectations.

1. Candy Production

Operate candy-making equipment, such as kettles, depositors, and molding machines, to create a variety of candy products.

- Monitor candy temperatures and adjust ingredients to achieve desired consistency and texture.

- Ensure that candy production meets safety and quality standards, following established recipes and procedures.

2. Candy Decoration

Apply various techniques to decorate and enhance the appearance of candies, using tools such as brushes, piping bags, and molds.

- Create intricate designs, patterns, and shapes using edible paints, frosting, and other decorative materials.

- Supervise and train assistants in decorating techniques to maintain consistency in product presentation.

3. Quality Control

Inspect and evaluate candies at various stages of production to ensure they meet quality and safety standards.

- Identify and rectify defects in candy appearance, texture, and taste.

- Maintain a clean and sanitary work environment to prevent contamination of candy products.

4. Equipment Maintenance

Clean and maintain candy-making equipment to ensure optimal performance and prevent breakdowns.

- Perform routine maintenance tasks, such as cleaning, lubricating, and calibrating equipment.

- Troubleshoot and resolve equipment issues, ensuring minimal downtime.

Interview Tips

To prepare effectively for an interview as a Novelty Candy Maker, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s culture, values, and the specific requirements of the Novelty Candy Maker position.

- Visit the company’s website, read industry articles, and connect with employees on LinkedIn.

- Thoroughly review the job description and identify the key skills and responsibilities.

2. Highlight Relevant Experience and Skills

Emphasize your experience in candy production, decoration, and quality control.

- Provide specific examples of your ability to operate candy-making equipment and create visually appealing candies.

- Quantify your accomplishments, such as the number of candies produced or the percentage of products that met quality standards.

3. Showcase Creativity and Attention to Detail

Novelty Candy Makers require a strong sense of creativity and an eye for detail.

- Bring a portfolio of your best candy creations to the interview.

- Describe specific techniques you use to decorate candies and ensure their presentation.

4. Prepare for Technical Questions

Be prepared to answer questions about candy-making processes and equipment.

- Study the basics of candy science, such as sugar crystallization and temperature control.

- Research common candy-making equipment and their functions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Novelty Candy Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.