Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Nozzle Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Nozzle Operator so you can tailor your answers to impress potential employers.

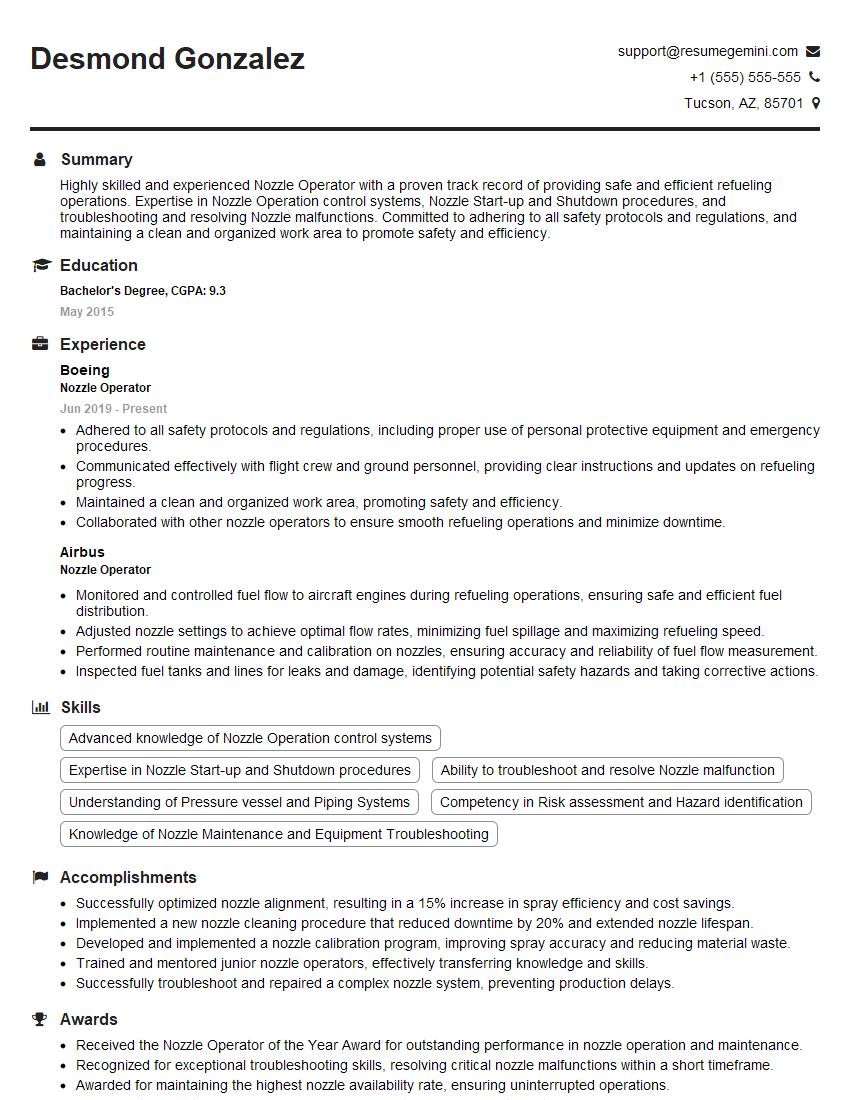

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nozzle Operator

1. Describe the main responsibilities of a Nozzle Operator.

- Monitor and operate nozzle equipment to apply protective coatings to surfaces.

- Control the flow, pressure, and temperature of the coating material.

- Inspect the coated surfaces for defects and ensure compliance with specifications.

- Maintain and calibrate equipment to ensure optimal performance.

- Follow safety protocols and maintain a clean and organized work area.

2. What are the different types of nozzle systems used in protective coating applications?

There are several types of nozzle systems used in protective coating applications, including:

Airless Sprayers

- Use high-pressure air to atomize the coating material

- Produce a fine, consistent finish

Air-Assisted Sprayers

- Combine compressed air and fluid pressure to atomize the coating

- Provide better control and reduce overspray

Conventional Sprayers

- Use compressed air to create a Venturi effect that atomizes the coating

- Produce a coarser finish but are less efficient

3. How do you determine the appropriate nozzle size and tip for a specific coating application?

- Consider the viscosity and flow rate of the coating material

- Choose a nozzle size that provides the desired spray pattern and coverage

- Select the appropriate tip based on the desired surface finish and thickness

- Refer to manufacturer’s specifications or consult with coating experts

4. What factors affect the quality of the coating application?

- Proper surface preparation

- Correct nozzle setup and maintenance

- Environmental conditions (temperature, humidity)

- Operator skill and experience

- Quality of the coating material

5. How do you troubleshoot common problems encountered during nozzle operation?

Common problems and troubleshooting steps include:

Clogged Nozzles

- Use a nozzle cleaning brush or solvent

- Check for debris or obstructions

Poor Spray Pattern

- Adjust the nozzle size or tip

- Check the air pressure or fluid flow

Overspray

- Reduce the spray pressure

- Use a smaller nozzle size or tip

6. How do you ensure the safety of yourself and others during nozzle operation?

- Wear appropriate personal protective equipment (PPE)

- Maintain a clean and organized work area

- Follow manufacturer’s instructions and safety protocols

- Inspect equipment regularly and report any concerns

- Stay aware of surroundings and potential hazards

7. What is your experience with quality control and inspection methods for protective coatings?

- Visual inspection for defects and surface finish

- Use of specialized equipment (e.g., thickness gauges, gloss meters)

- Adherence testing to ensure proper bonding

- Compliance with industry standards and specifications

8. How do you handle situations where the coating does not meet the desired specifications?

- Identify the root cause of the problem

- Adjust the nozzle settings or coating parameters as necessary

- Re-inspect the coated surface and make any necessary repairs

- Document the issue and implement corrective actions to prevent recurrence

9. Describe your experience with different types of protective coatings.

- Epoxies

- Polyurethanes

- Acrylics

- Fluoropolymers

- Ceramic coatings

10. What is your understanding of the environmental regulations and safety protocols for handling and applying protective coatings?

- OSHA regulations

- EPA regulations

- Proper disposal of coating materials and equipment

- Use of low-VOC and environmentally friendly coatings

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nozzle Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nozzle Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nozzle Operators are highly skilled professionals responsible for operating and maintaining nozzles in a variety of industrial settings. They play a crucial role in ensuring the safe and efficient operation of equipment and production processes. Key responsibilities of a Nozzle Operator include:

1. Nozzle Operation

Operate and control nozzles to apply coatings, sealants, or other materials to surfaces. Ensure proper nozzle settings and adjustments to achieve desired application results. Monitor nozzle performance and make necessary adjustments to optimize application quality.

2. Equipment Maintenance

Perform regular inspections and maintenance on nozzle equipment to prevent breakdowns. Clean and lubricate nozzles and related components to maintain optimal performance. Identify and troubleshoot nozzle malfunctions and take corrective actions to minimize downtime.

3. Process Monitoring

Monitor production processes to ensure proper application of materials. Inspect applied materials to verify quality and adherence to specifications. Document process parameters and identify any deviations from established standards.

4. Safety Compliance

Adhere to all safety protocols and regulations related to nozzle operation. Wear appropriate personal protective equipment and follow prescribed safety procedures. Maintain a clean and organized work area to prevent hazards.

Interview Tips

Preparing thoroughly for a Nozzle Operator interview is crucial for success. Here are some tips to help you ace the interview:

1. Research the Company and Role

Before the interview, take the time to research the company and the specific nozzle operator role. Understand the company’s products, services, and industry position. Familiarize yourself with the job description and identify key responsibilities and qualifications.

2. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience that match the job requirements. Quantify your accomplishments and provide specific examples that demonstrate your abilities in nozzle operation, equipment maintenance, and process monitoring.

- “In my previous role, I consistently achieved production targets by optimizing nozzle settings and minimizing downtime. I reduced nozzle maintenance costs by 15% through preventive maintenance and timely repairs.”

- “I possess strong troubleshooting skills and quickly identify and resolve nozzle malfunctions. I have a proven track record of maintaining equipment uptime and ensuring smooth production processes.”

3. Prepare for Common Interview Questions

Practice answering common interview questions related to nozzle operation, safety, and problem-solving. Prepare concise and articulate responses that showcase your knowledge and experience. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

4. Ask Informed Questions

Towards the end of the interview, prepare thoughtful questions to ask the interviewer. This demonstrates your interest in the role and the company. Questions about the company’s growth plans, training opportunities, or safety initiatives can be appropriate.

5. Dress Professionally and Be Punctual

A professional appearance and punctuality reflect your respect for the interviewer and the company. Dress appropriately for the industry and role, and arrive on time for the interview. Maintaining good eye contact and a positive attitude throughout the interview makes a lasting impression.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Nozzle Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Nozzle Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.