Are you gearing up for an interview for a Nozzle Tender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Nozzle Tender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

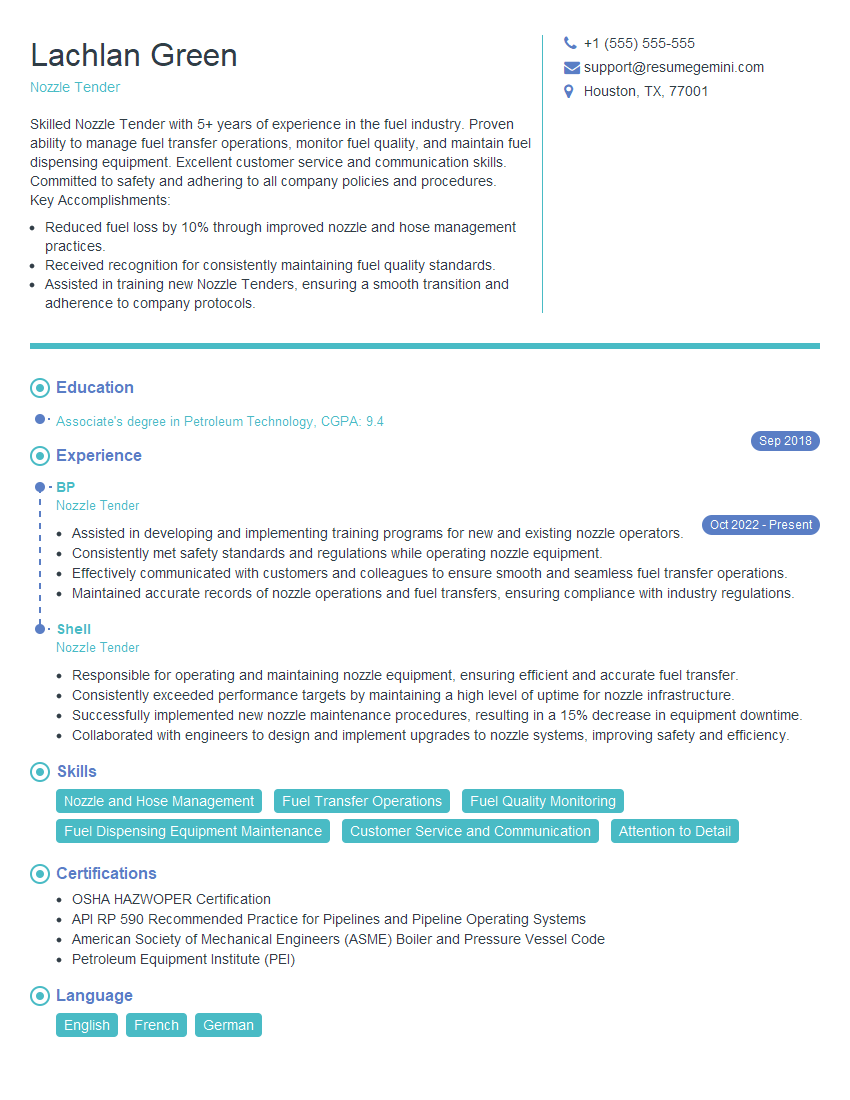

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nozzle Tender

1. Explain the key responsibilities of a Nozzle Tender in a manufacturing environment?

As a Nozzle Tender, I am responsible for:

- Operating and maintaining nozzle equipment for the production process

- Monitoring and adjusting nozzle settings to ensure optimal performance

- Performing routine maintenance on nozzles and other equipment

- Ensuring the quality of the finished product by monitoring the spraying process

- Troubleshooting and resolving any problems that may arise with the equipment

2. Describe the different types of nozzles used in manufacturing and their applications?

Types of Nozzles:

- Spray Nozzles: Used for spraying liquids in a cone or fan-shaped pattern

- Air Nozzles: Used for drying, cooling, or conveying materials

- Atomizing Nozzles: Used for creating a fine mist or aerosol

- Hydraulic Nozzles: Used for generating high-pressure water jets

Applications:

- Spray Nozzles: Painting, coating, cleaning, humidification

- Air Nozzles: Drying, cooling, conveying

- Atomizing Nozzles: Fuel injection, lubrication, misting

- Hydraulic Nozzles: Cutting, cleaning, surface preparation

3. What are the factors that affect the performance of a nozzle?

- Nozzle design (shape, size, and material)

- Flow rate and pressure

- Fluid properties (viscosity, density)

- Environmental conditions (temperature, humidity)

- Maintenance and calibration

4. Explain the steps involved in troubleshooting a nozzle problem?

Steps to Troubleshoot Nozzle Problems

- Identify the symptoms (e.g., poor spray pattern, clogging)

- Check for obvious issues (e.g., loose connections, damaged parts)

- Inspect the nozzle for blockages or wear

- Verify the flow rate and pressure

- Check the fluid properties

- Calibrate the nozzle if necessary

- Replace the nozzle if it is damaged or worn

5. What safety precautions should be taken when working with nozzles?

- Wear appropriate PPE (gloves, safety glasses, hearing protection)

- Follow lockout/tagout procedures when performing maintenance

- Be aware of the potential for pressure hazards

- Handle fluids safely and responsibly

- Keep work area clean and organized

6. Describe your experience with different types of manufacturing processes?

I have worked in various manufacturing processes, including:

- Automotive manufacturing

- Aerospace manufacturing

- Food and beverage processing

- Pharmaceutical manufacturing

- Electronics manufacturing

7. What are the quality standards that apply to nozzle operations?

- ISO 9001:2015

- ASME BPE

- FDA regulations

- Customer-specific requirements

8. How do you ensure the quality of the finished product in your work as a Nozzle Tender?

- Monitoring the spraying process

- Inspecting the finished product

- Calibrating and maintaining equipment

- Following quality control procedures

- Working closely with quality assurance team

9. What are some of the challenges you have faced as a Nozzle Tender?

- Troubleshooting complex nozzle problems

- Maintaining quality standards in high-volume production environments

- Working in hazardous environments

- Meeting deadlines and production targets

- Keeping up with advancements in nozzle technology

10. How do you stay up-to-date with the latest nozzle technologies?

- Attending industry conferences and training courses

- Reading industry publications and white papers

- Networking with other nozzle professionals

- Working with nozzle manufacturers

- Exploring new technologies through research and development

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nozzle Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nozzle Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nozzle Tenders are responsible for maintaining and operating nozzles, which are used to spray various fluids or materials. They ensure that the nozzles are functioning properly and that the fluids are being dispensed correctly.

1. Nozzle Maintenance

Nozzle Tenders perform regular maintenance on nozzles, including cleaning, inspecting, and replacing worn or damaged parts. They also ensure that the nozzles are properly calibrated and adjusted to dispense the correct amount and type of fluid.

- Clean and inspect nozzles to ensure they are free of debris and damage.

- Replace worn or damaged parts to maintain nozzle functionality.

- Calibrate and adjust nozzles to dispense the correct amount and type of fluid.

2. Nozzle Operation

Nozzle Tenders operate nozzles to dispense fluids or materials. They adjust the flow rate and pressure of the fluids to meet specific requirements. They also monitor the operation of the nozzles to ensure that they are functioning properly.

- Adjust the flow rate and pressure of fluids to meet specific requirements.

- Monitor the operation of nozzles to ensure they are functioning properly.

- Troubleshoot and resolve any issues with nozzle operation.

3. Fluid Management

Nozzle Tenders manage the fluids used in nozzles. They ensure that the fluids are properly stored and handled. They also monitor the fluid levels and replenish them as needed.

- Ensure that fluids are properly stored and handled.

- Monitor fluid levels and replenish them as needed.

- Dispose of waste fluids according to environmental regulations.

4. Safety and Compliance

Nozzle Tenders must adhere to safety and compliance regulations when working with nozzles and fluids. They must follow proper procedures for handling and using fluids and equipment. They also must wear appropriate personal protective equipment (PPE) to protect themselves from hazards.

- Follow proper procedures for handling and using fluids and equipment.

- Wear appropriate personal protective equipment (PPE) to protect themselves from hazards.

- Comply with all applicable safety and environmental regulations.

Interview Tips

To prepare for an interview for a Nozzle Tender position, it is important to highlight your skills and experience in nozzle maintenance, operation, and fluid management. You should also demonstrate your knowledge of safety and compliance regulations.

1. Research the Company

Before the interview, research the company to learn about their business and the specific role you are interviewing for. This will help you understand the company’s culture and the expectations for the position.

- Visit the company’s website to learn about their products, services, and history.

- Read news articles and industry publications to learn about the company’s recent developments and initiatives.

- Check the company’s social media pages to get a sense of their culture and values.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Brainstorm potential questions that the interviewer may ask.

- Write out your answers and practice saying them out loud.

- Get feedback from a friend or family member on your answers.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the company’s culture.

- Choose clothing that is comfortable and allows you to move freely.

- Avoid wearing clothing that is too revealing or too casual.

- Make sure your clothes are clean and free of wrinkles.

4. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be confident in your abilities and experience.

- Be honest and open about your strengths and weaknesses.

- Show the interviewer that you are enthusiastic about the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nozzle Tender interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.