Feeling lost in a sea of interview questions? Landed that dream interview for Numerical Control Drill Press Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Numerical Control Drill Press Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

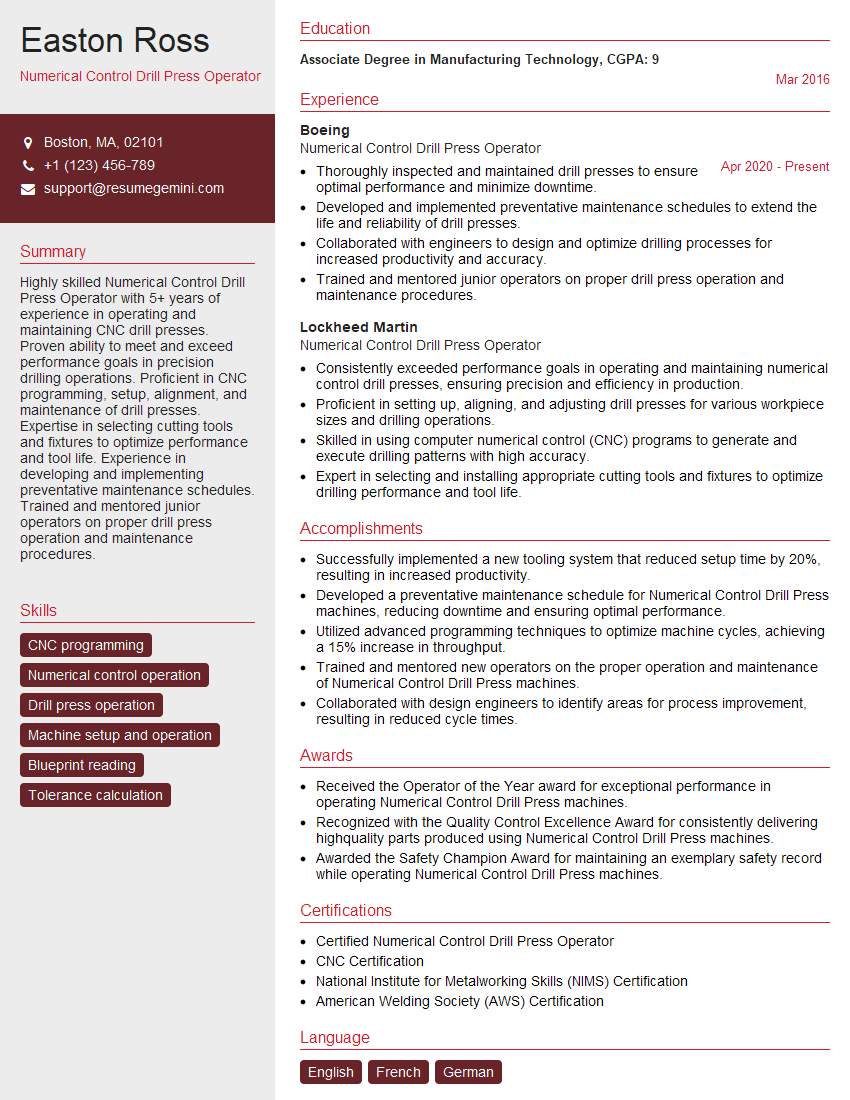

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Numerical Control Drill Press Operator

1. What is the difference between absolute and incremental programming, and when would you use each one?

Absolute programming specifies the exact position of the drill bit in relation to the machine’s home position. Incremental programming specifies the distance that the drill bit should move relative to its current position. Absolute programming is used when you need to drill a hole at a precise location, while incremental programming is used when you need to drill a hole relative to another hole or feature.

2. Describe the different types of drill bits and how to select the right one for the job.

High-Speed Steel (HSS) drill bits

- Popular choice for general-purpose drilling

- Available in a variety of sizes and shapes

- Not as durable as carbide drill bits, but less expensive

Carbide drill bits

- More durable than HSS drill bits

- Can drill through harder materials

- More expensive than HSS drill bits

Cobalt drill bits

- Even more durable than carbide drill bits

- Can drill through the hardest materials

- Most expensive type of drill bit

3. How do you calculate the feed rate for a drill press?

The feed rate is the rate at which the drill bit advances into the workpiece. It is typically measured in inches per minute (IPM). The feed rate is calculated by dividing the spindle speed by the number of flutes on the drill bit.

4. What is the importance of using coolant when drilling?

Coolant is a liquid that is used to lubricate the drill bit and workpiece and to remove chips. It helps to keep the drill bit cool and prevents it from overheating and wearing out prematurely. Coolant also helps to flush away chips, which can improve the accuracy and finish of the hole.

5. How do you set up and calibrate a drill press?

- Mount the drill bit in the chuck and tighten it securely.

- Adjust the table height so that the workpiece is at the correct height for drilling.

- Zero the digital readout (DRO) on the drill press.

- Use a test piece to calibrate the DRO by drilling a hole and measuring the depth with a micrometer.

6. What are the safety precautions that should be taken when operating a drill press?

- Always wear safety glasses and earplugs.

- Tie back long hair and loose clothing.

- Clear the area around the drill press of any obstructions.

- Never operate the drill press with a dull or damaged drill bit.

- Always use coolant when drilling.

7. How do you troubleshoot a drill press that is not working properly?

- Check the power supply to make sure that the drill press is getting power.

- Check the drill bit to make sure that it is sharp and not damaged.

- Check the coolant supply to make sure that the drill bit is getting lubricated.

- Check the chuck to make sure that the drill bit is tightened securely.

- Check the spindle speed and feed rate to make sure that they are set correctly.

8. What are some of the common maintenance tasks that should be performed on a drill press?

- Clean the drill press regularly to remove chips and debris.

- Lubricate the moving parts of the drill press regularly.

- Inspect the drill bit regularly for wear and tear.

- Calibrate the drill press regularly to ensure that it is drilling holes accurately.

9. What are some of the advanced features that are available on newer drill presses?

- Automatic tool changers

- Laser positioning systems

- CNC controls

- Variable speed motors

- Automatic depth control

10. How do you stay updated on the latest developments in drill press technology?

- Read industry publications.

- Attend trade shows.

- Talk to other drill press operators.

- Take online courses.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Numerical Control Drill Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Numerical Control Drill Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Numerical Control (NC) Drill Press Operators play a crucial role in manufacturing industries by operating computerized drill presses to create precise holes and patterns in metal, wood, and plastic components.

1. Machine Operation

Highly skilled Numerical Control Drill Press Operators must possess a thorough understanding of the advanced features and capabilities of their machines. They are responsible for programming, setting up, and operating NC drill presses to perform complex drilling operations.

- Program drills using computer-aided design (CAD) software to specify hole depths, diameters, and patterns.

- Ensure proper installation of cutting tools, drill bits, and workpieces into the drill press.

- Monitor the drilling process to ensure precision and adherence to specifications.

2. Quality Control

Numerical Control Drill Press Operators prioritize quality assurance by performing regular inspections and taking accurate measurements throughout the drilling process. They are vigilant in detecting and addressing any deviations from the desired specifications.

- Inspect drilled holes for adherence to dimensional tolerances and surface finish requirements.

- Calibrate and maintain measuring equipment to guarantee accuracy and reliability.

- Identify and resolve any discrepancies or defects in the drilling process, ensuring the production of high-quality components.

3. Production Management

Efficient Numerical Control Drill Press Operators proactively manage their production schedules, optimizing machine uptime and minimizing downtime. They continuously seek ways to enhance productivity while maintaining the highest levels of quality.

- Plan and prioritize drilling operations based on production targets and deadlines.

- Monitor machine performance to identify areas for improvement and efficiency gains.

- Troubleshoot equipment malfunctions and resolve any operational issues promptly.

4. Safety and Maintenance

Numerical Control Drill Press Operators are committed to maintaining a safe and efficient work environment. They are well-versed in proper machine operation, adhering to all safety protocols and regulations.

- Observe all safety guidelines and follow established procedures to prevent accidents.

- Regularly clean and lubricate the drill press to ensure optimal performance.

- Report any potential hazards or equipment malfunctions promptly to ensure a safe work area.

Interview Preparation Tips

Interview preparation is essential to showcase your qualifications and make a positive impression on the hiring manager. Follow these tips to enhance your chances of success:

1. Know the Job Description Inside Out

Thoroughly study the job description to understand the specific responsibilities, required skills, and qualifications. This will help you tailor your answers to the interviewer’s questions and demonstrate your fit for the position.

2. Practice Your Answers

Prepare thoughtful answers to common interview questions. Anticipate potential scenarios and questions related to your experience, technical abilities, and problem-solving approach. Practice your responses to convey your key strengths and enthusiasm for the role.

3. Highlight Your Technical Proficiency

Emphasize your expertise in operating NC drill presses, including your knowledge of programming, setup procedures, and quality control techniques. Provide specific examples of your accomplishments that showcase your ability to produce high-quality work efficiently.

4. Showcase Your Attention to Detail

Numerical Control Drill Press Operators play a crucial role in ensuring the accuracy and precision of manufactured parts. Highlight your strong attention to detail, your ability to identify and correct errors, and your commitment to meeting the highest standards of quality.

5. Demonstrate Your Communication Ability

While technical skills are paramount, effective communication is also vital. Practice articulating your ideas clearly, both in written and verbal formats. The interviewer needs to assess your ability to communicate with colleagues, supervisors, and customers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Numerical Control Drill Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.