Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Numerical Control Lathe Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Numerical Control Lathe Operator so you can tailor your answers to impress potential employers.

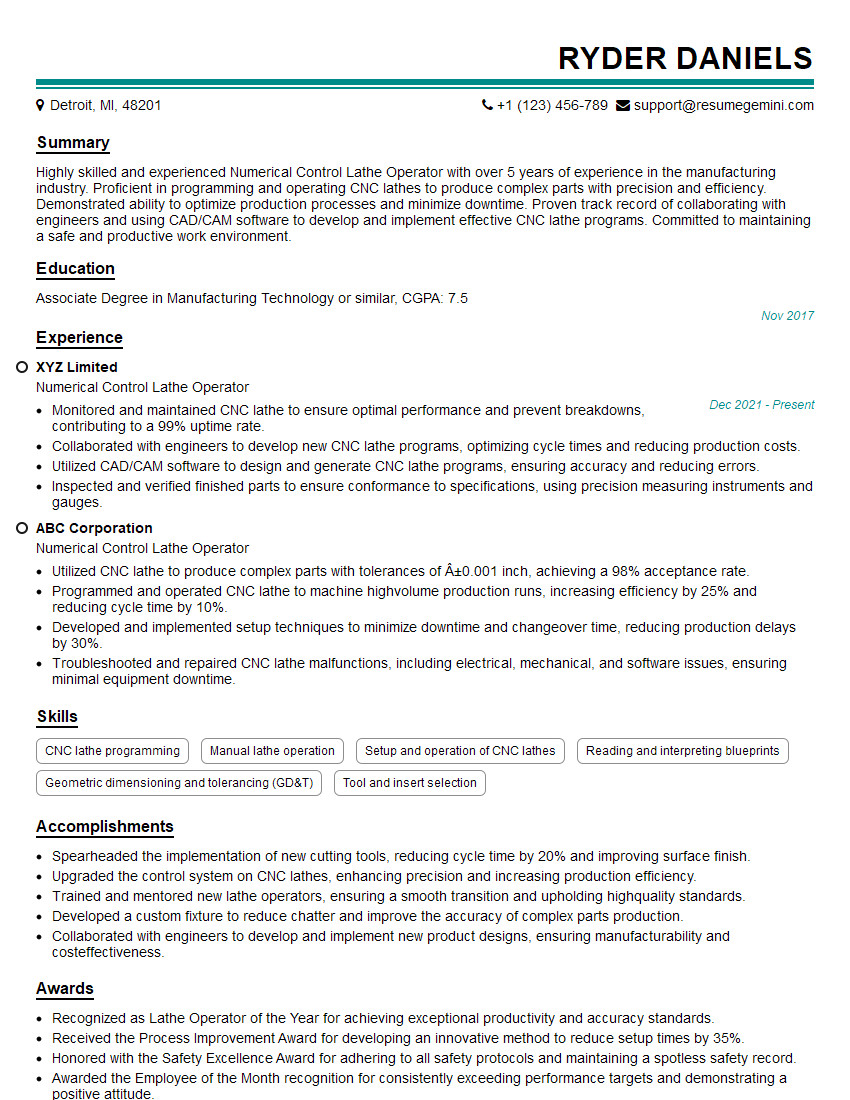

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Numerical Control Lathe Operator

1. What are the key responsibilities of a Numerical Control Lathe Operator?

- Setting up and operating CNC lathes to produce parts according to specifications.

- Interpreting blueprints and technical drawings to determine machining parameters.

- Selecting and installing cutting tools and workholding devices.

- Monitoring the machining process and making adjustments as needed.

- Measuring and inspecting parts to ensure they meet quality standards.

2. What types of CNC lathes have you worked with?

- I have worked with a variety of CNC lathes, including 2-axis, 3-axis, and 4-axis machines.

- I am familiar with the different types of CNC controls, including Fanuc, Siemens, and Heidenhain.

3. What is G-code?

G-code is a programming language used to control CNC machines.

- It is a set of instructions that tell the machine how to move its axes, spindle, and other components.

- I am proficient in writing and editing G-code programs.

4. What is the difference between absolute and incremental programming?

- Absolute programming uses the machine’s home position as the reference point for all movements.

- Incremental programming uses the current position of the machine as the reference point for all movements.

- I am familiar with both types of programming and can use them effectively.

5. What are the different types of cutting tools used in CNC lathe operations?

- There are many different types of cutting tools used in CNC lathe operations, including turning tools, facing tools, boring tools, and grooving tools.

- I am familiar with the different types of cutting tools and can select the appropriate tool for the job.

6. How do you ensure that the parts you produce meet the required quality standards?

- I use a variety of methods to ensure that the parts I produce meet the required quality standards, including visual inspection, dimensional inspection, and surface finish inspection.

- I am committed to producing high-quality parts and I take pride in my work.

7. What is your experience with CNC lathe maintenance?

- I have experience with basic CNC lathe maintenance tasks, such as cleaning and lubricating the machine, and changing the coolant.

- I am also familiar with more advanced maintenance tasks, such as troubleshooting electrical problems and mechanical issues.

8. What are your strengths as a CNC lathe operator?

- I am a highly skilled CNC lathe operator with over 5 years of experience.

- I am proficient in all aspects of CNC lathe operation, from programming to setup to operation.

- I am also a team player and I am always willing to help out my coworkers.

9. What are your weaknesses as a CNC lathe operator?

- One of my weaknesses is that I can be a bit slow at times when it comes to programming complex parts.

- However, I am always working to improve my skills and I am confident that I can overcome this weakness.

10. What are your career goals?

- My career goal is to become a CNC lathe programmer.

- I am confident that I have the skills and experience necessary to be successful in this role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Numerical Control Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Numerical Control Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Numerical Control (NC) Lathe Operators are responsible for operating and maintaining precision lathes and other machine tools to produce high-quality parts. They must be able to interpret blueprints and drawings, program the NC lathe, and troubleshoot any problems that arise.

1. Operating the Lathe

NC Lathe Operators are responsible for setting up and operating the lathe, including selecting the appropriate tooling, determining the cutting speeds and feeds, and monitoring the operation of the machine.

- Set up and operate the NC lathe according to blueprints and drawings.

- Select the appropriate cutting tools, cutting speeds, and feeds for each job.

- Monitor the operation of the lathe and make any necessary adjustments.

2. Programming the Lathe

NC Lathe Operators must be able to program the lathe to perform the desired operations. This involves creating a program that specifies the path of the cutting tool, the cutting speeds and feeds, and other parameters.

- Create and edit NC programs using a computer-aided design (CAD) program.

- Download the NC program to the lathe controller.

- Troubleshoot any problems with the NC program.

3. Maintaining the Lathe

NC Lathe Operators are also responsible for maintaining the lathe and other equipment in good working order. This includes cleaning and lubricating the machine, changing the cutting tools, and making any necessary repairs.

- Clean and lubricate the lathe and other equipment.

- Change the cutting tools.

- Make any necessary repairs to the lathe and other equipment.

4. Quality Control

NC Lathe Operators are responsible for ensuring that the parts they produce meet the required quality standards. This involves inspecting the parts for accuracy, finish, and other specifications.

- Inspect the parts for accuracy, finish, and other specifications.

- Identify any defects and correct them.

- Document the inspection results.

Interview Tips

Preparing for an interview for a Numerical Control Lathe Operator position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before you go to the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position.

- Visit the company’s website.

- Read the job description carefully.

- Research the industry and the specific job title.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is important to practice answering these questions in advance so that you can deliver clear and concise responses.

- Prepare a list of common interview questions and practice answering them.

- Ask a friend or family member to role-play an interview with you.

- Time yourself to make sure you can answer the questions within the allotted time.

3. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the position. This includes your technical skills, such as your experience with NC lathes and programming, as well as your soft skills, such as your attention to detail and your ability to work independently.

- Provide specific examples of your skills and experience.

- Quantify your accomplishments whenever possible.

- Relate your skills and experience to the specific requirements of the position.

4. Dress Professionally and Be on Time

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also arrive on time for your interview. Arriving late or being unprepared will reflect poorly on you.

- Dress professionally in clean, pressed clothes and shoes.

- Arrive on time for your interview.

- Bring a copy of your resume and any other relevant materials.

Next Step:

Now that you’re armed with the knowledge of Numerical Control Lathe Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Numerical Control Lathe Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini