Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Numerical Control Milling Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Numerical Control Milling Machine Operator so you can tailor your answers to impress potential employers.

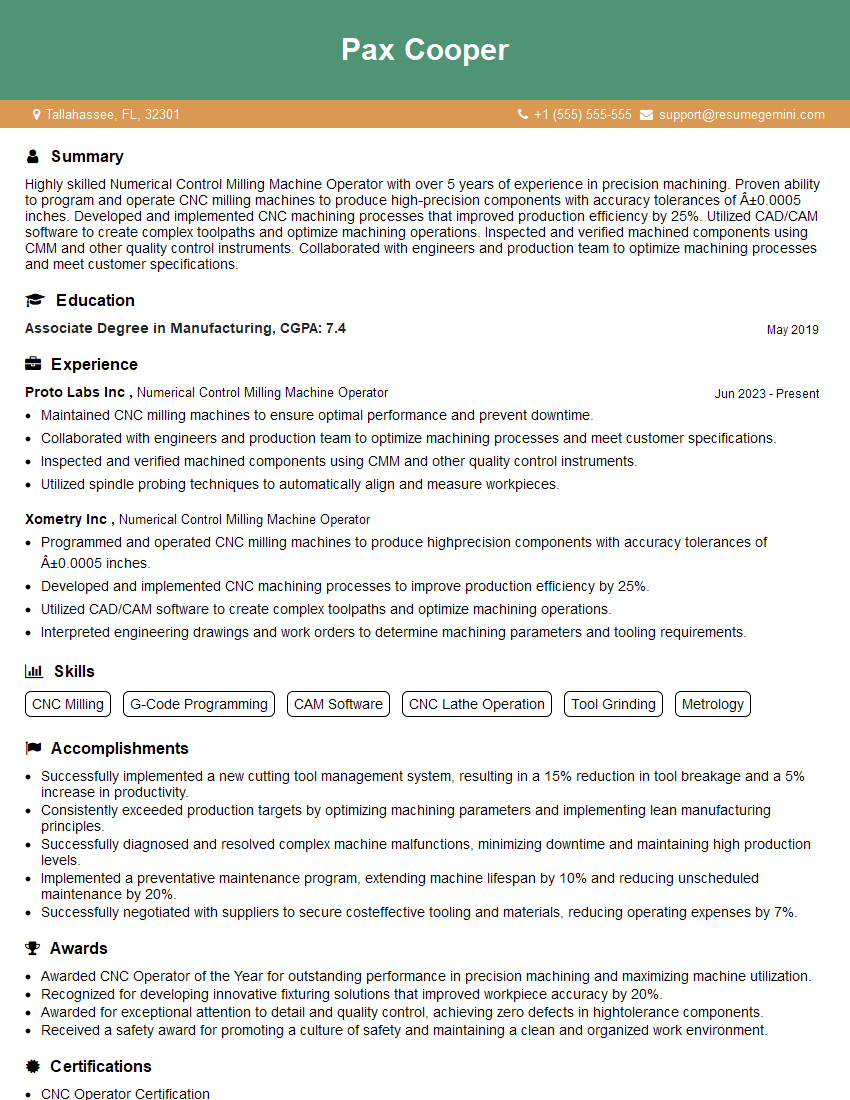

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Numerical Control Milling Machine Operator

1. Describe the process of setting up a Numerical Control Milling Machine.

The setup process involves several steps:

- Secure the workpiece to the machine table using clamps or a fixture.

- Install the appropriate cutting tool into the spindle.

- Set the machine’s parameters, including feed rate, spindle speed, and depth of cut.

- Load the CNC program into the machine’s controller.

- Run a dry run to verify the program and ensure there are no collisions.

2. How do you ensure workpiece precision when operating a CNC Milling Machine?

Precision Maintenance:

- Regularly calibrate the machine and its components.

- Inspect cutting tools for wear and replace them as needed.

Program Optimization:

- Use the appropriate cutting parameters for the workpiece material.

- Optimize toolpaths to minimize chatter and vibration.

Measurement and Inspection:

- Use precision measuring tools to verify workpiece dimensions.

- Implement statistical process control to monitor and improve precision.

3. What cutting tool materials are commonly used in CNC Milling and what are their applications?

- Carbide: High hardness and wear resistance, suitable for cutting hard materials.

- High-Speed Steel (HSS): Affordable and versatile, commonly used for general-purpose machining.

- Cemented Carbide: Combination of carbide and metal binder, provides a balance of hardness and toughness.

- Diamond: Extremely hard and wear-resistant, used for cutting non-metallic materials like glass and ceramics.

4. Explain the concept of coolant usage in CNC Milling.

- Lubricate the cutting tool and workpiece, reducing friction and heat.

- Cool the workpiece, preventing thermal distortion.

- Remove chips and debris from the cutting zone.

- Protect the cutting tool from wear and extend its lifespan.

5. How do you troubleshoot common problems that occur during CNC Milling operations?

- Tool breakage: Check for worn or damaged tools, incorrect cutting parameters, or excessive vibration.

- Poor surface finish: Adjust cutting parameters, optimize toolpaths, or ensure proper tool maintenance.

- Dimensional inaccuracies: Calibrate the machine, check for mechanical backlash, or adjust the program parameters.

- Spindle vibration: Balance the spindle, check for loose bearings, or adjust the spindle speed.

6. Describe the safety measures you adhere to when operating a CNC Milling Machine.

- Wear appropriate safety gear, including closed-toe shoes, safety glasses, and hearing protection.

- Ensure the machine is properly grounded and electrically isolated.

- Keep the work area clean and free of debris.

- Never attempt to remove chips or adjust the machine while it is in operation.

- Follow lockout/tagout procedures when servicing or repairing the machine.

7. How do you stay updated on the latest advancements in CNC Milling technology?

- Attend industry conferences and exhibitions.

- Read technical journals and online resources.

- Participate in training programs offered by machine manufacturers.

- Network with other CNC professionals and share knowledge.

8. What strategies do you use to reduce production costs while maintaining high-quality standards in CNC Milling?

- Optimize toolpaths and cutting parameters to reduce cycle times.

- Use efficient tooling and fixturing to minimize changeover time.

- Implement automated processes, such as automatic tool changers and chip conveyors.

- Monitor machine performance and identify areas for improvement.

9. How do you handle complex CNC Milling projects that require precision and accuracy?

Complex projects require meticulous planning and execution:

- Create detailed work instructions and drawings.

- Use specialized tooling and fixtures to ensure precision.

- Implement quality control measures throughout the process.

- Collaborate with engineers and designers to optimize the design and machining process.

10. What are the challenges you have faced in your previous CNC Milling roles and how did you overcome them?

Describe specific challenges and how:

- Analyzed the problem and identified its root cause.

- Explored multiple solutions and implemented the most effective one.

- Collaborated with team members or external experts to find solutions.

- Learned from the experience and developed strategies to prevent similar issues in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Numerical Control Milling Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Numerical Control Milling Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Numerical Control Milling Machine Operators are responsible for operating and maintaining numerical control (NC) milling machines to produce metal parts. They use computer-aided design (CAD) software to create tool paths and control the machine’s movements. NC Milling Machine Operators must have a strong understanding of machining principles and be able to troubleshoot mechanical problems.

1. Set up and operate NC milling machines

NC Milling Machine Operators set up and operate NC milling machines to produce metal parts. They use CAD software to create tool paths and control the machine’s movements. They also must be able to troubleshoot mechanical problems.

- Set up and align workpieces and fixtures on the machine table

- Load and unload parts from the machine

- Operate the machine according to the program instructions

- Monitor the machine’s operation and make adjustments as needed

- Troubleshoot mechanical problems and make repairs

2. Inspect parts for quality

NC Milling Machine Operators inspect parts for quality after they have been produced. They check for dimensional accuracy, surface finish, and other quality requirements. They also make adjustments to the machine or the program as needed to improve the quality of the parts.

- Check parts for dimensional accuracy using measuring instruments

- Inspect parts for surface finish and other quality requirements

- Make adjustments to the machine or the program as needed to improve the quality of the parts

3. Maintain the milling machine

NC Milling Machine Operators are responsible for maintaining the milling machine. They perform regular maintenance tasks, such as cleaning and lubricating the machine, and replacing worn parts. They also troubleshoot mechanical problems and make repairs as needed.

- Clean and lubricate the machine

- Replace worn parts

- Troubleshoot mechanical problems and make repairs

4. Follow safety procedures

NC Milling Machine Operators must follow safety procedures when operating the machine. They wear appropriate safety gear, such as safety glasses and gloves, and they keep the work area clean and free of debris. They also follow lockout/tagout procedures when performing maintenance on the machine.

- Wear appropriate safety gear

- Keep the work area clean and free of debris

- Follow lockout/tagout procedures

Interview Tips

Preparing for an interview for a Numerical Control Milling Machine Operator position can be daunting, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website

- Read about the company’s products or services

- Learn about the company’s culture and values

- Review the job description

- Identify the key skills and experience that the employer is looking for

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Use the STAR method to answer questions

- STAR stands for Situation, Task, Action, Result

- When answering questions, be sure to give specific examples of your skills and experience

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Numerical Control Milling Machine Operator. Be prepared to talk about your experience in detail, including the specific types of machines you have operated and the types of parts you have produced.

- Highlight your skills and experience in the following areas:

- Machine operation

- Part production

- Quality control

- Machine maintenance

4. Be prepared to answer questions about your safety knowledge

Safety is very important in the manufacturing industry. The interviewer will want to know about your safety knowledge and experience. Be prepared to answer questions about the safety procedures you follow when operating a milling machine.

- Explain the importance of following safety procedures

- Describe the safety procedures you follow when operating a milling machine

- Discuss your experience with lockout/tagout procedures

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Numerical Control Milling Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!