Are you gearing up for an interview for a Numerical Control Milling Machine Set-Up Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Numerical Control Milling Machine Set-Up Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

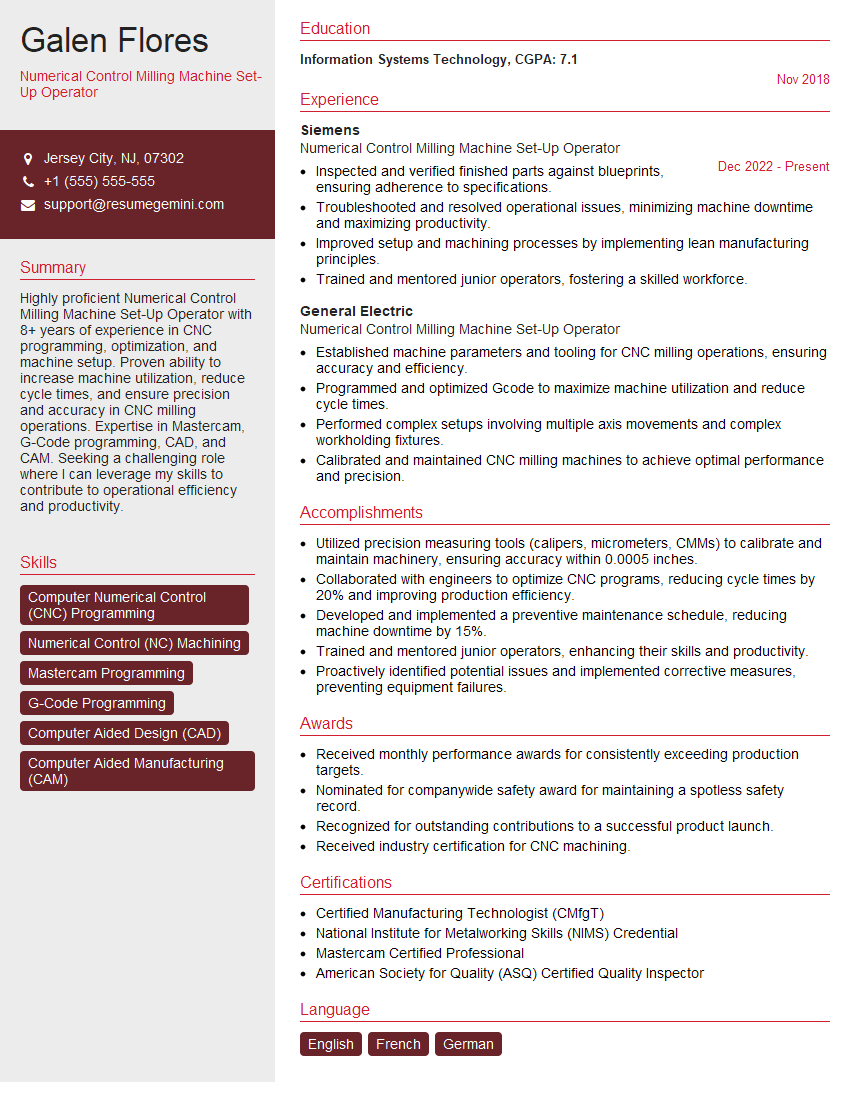

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Numerical Control Milling Machine Set-Up Operator

1. What are the key responsibilities of a Numerical Control Milling Machine Set-Up Operator?

The key responsibilities of a Numerical Control Milling Machine Set-Up Operator include:

- Setting up and operating numerical control (NC) milling machines

- Programming NC milling machines using computer-aided manufacturing (CAM) software

- Inspecting and measuring finished parts to ensure accuracy and precision

- Maintaining and repairing NC milling machines and other equipment

- Following safety protocols and procedures

2. What are the different types of NC milling machines?

The different types of NC milling machines include:

Vertical milling machines

- Bed type

- Knee type

- Turcite type

Horizontal milling machines

- Column and knee type

- Planer type

- Travelling column type

- Floor type

3. What are the different types of cutting tools used in NC milling?

- End mills

- Ball nose cutters

- Face mills

- Slot cutters

- Drills

- Taps

- Reamer

4. What are the key factors to consider when selecting cutting tools for NC milling?

The key factors to consider when selecting cutting tools for NC milling include:

- The type of material being machined

- The desired surface finish

- The cutting speed

- The feed rate

- The depth of cut

- The type of coolant being used

5. What are the common problems that can occur during NC milling?

- Tool breakage

- Chatter

- Burrs

- Dimensional errors

- Surface finish problems

6. How do you troubleshoot common problems that occur during NC milling?

Troubleshooting common problems that occur during NC milling involve the following steps:

- Identifying the problem

- Determining the cause of the problem

- Developing a solution to the problem

- Implementing the solution

- Verifying that the solution has resolved the problem

7. What are the safety protocols and procedures that must be followed when operating NC milling machines?

Safety protocols and procedures that must be followed when operating NC milling machines include:

- Wearing appropriate personal protective equipment (PPE)

- Keeping the work area clean and free of debris

- Following proper machine operating procedures

- Being aware of the hazards associated with NC milling

- Reporting any unsafe conditions or practices to supervisor

8. What are the different types of CAM software used for programming NC milling machines?

Different types of CAM software used for programming NC milling machines include:

- Mastercam

- SolidWorks CAM

- NX CAM

- CATIA CAM

- Siemens NX

9. What are the different types of toolpaths that can be generated using CAM software?

The different types of toolpaths that can be generated using CAM software include:

- Straight line toolpaths

- Circular toolpaths

- Helical toolpaths

- Freeform toolpaths

- Surface finishing toolpaths

10. What are the key factors to consider when generating toolpaths for NC milling?

The key factors to consider when generating toolpaths for NC milling include:

- The type of material being machined

- The desired surface finish

- The cutting speed

- The feed rate

- The depth of cut

- The type of cutting tool being used

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Numerical Control Milling Machine Set-Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Numerical Control Milling Machine Set-Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Numerical Control Milling Machine Set-Up Operators are responsible for setting up and operating numerically controlled (NC) milling machines. They work closely with engineers and other manufacturing professionals to ensure that parts are produced according to specifications.

1. Machine Setup and Operation

Set up and operate NC milling machines according to blueprints and specifications.

- Inspect and clean all machine components.

- Load and secure work pieces in the machine.

- Select and install appropriate cutting tools.

- Program and input operating parameters into the machine controller.

- Monitor the machine during operation and make adjustments as needed.

2. Inspection and Quality Control

Inspect finished parts for accuracy and quality using measuring tools and equipment.

- Compare the produced parts to the specified requirements and tolerances.

- Identify and correct any errors or defects.

- Maintain records of inspection results.

3. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting of the machine and its components.

- Lubricate and clean the machine regularly.

- Identify and replace worn or damaged parts.

- Troubleshoot and resolve any operational issues.

4. Compliance and Safety

Follow all safety regulations and procedures.

- Wear appropriate personal protective equipment.

- Operate the machine in a well-ventilated area.

- Comply with all applicable environmental regulations.

Interview Tips

Preparing for an interview for a Numerical Control Milling Machine Set-Up Operator position is crucial to showcase your skills and knowledge and impress the hiring manager.

1. Research Company and Industry

Read about the company’s history, products, and services. Understand the industry and its trends. It helps you align your answers with the company’s goals and demonstrate your interest.

2. Practice Your Technical Skills

Go through the job description and identify the required technical skills. Practice operating an NC milling machine using simulation software or online resources.

3. Highlight Your Experience

Emphasize your experience setting up and operating NC milling machines in previous roles. Quantify your accomplishments, using specific examples to demonstrate your impact.

4. Prepare for Common Interview Questions

Interviewers often ask questions about your problem-solving abilities, troubleshooting experience, and safety procedures. Practice answering these questions using the STAR (Situation, Task, Action, Result) method.

5. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately for an office setting and arrive at the interview on time. Your professional appearance and punctuality show respect for the company and the hiring manager.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Numerical Control Milling Machine Set-Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!