Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Numerical Control Operator (NC Operator) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

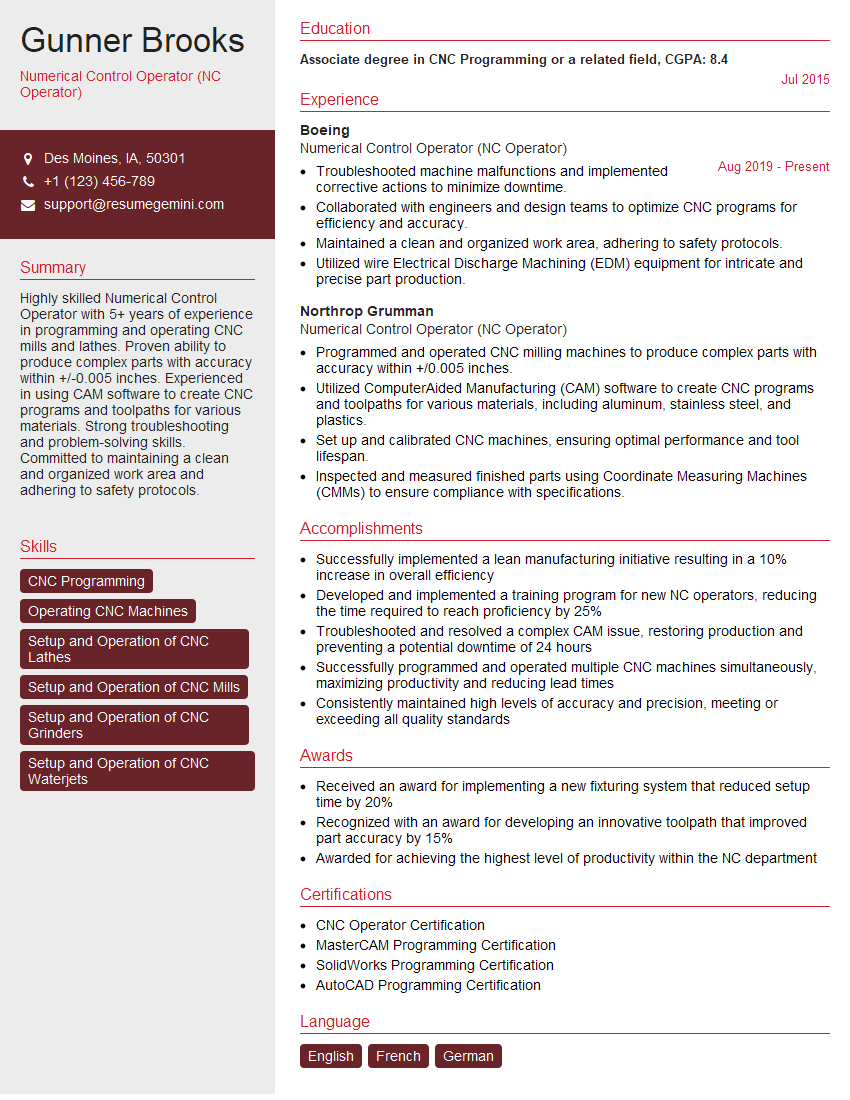

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Numerical Control Operator (NC Operator)

1. What are the key responsibilities of a Numerical Control Operator?

As an NC Operator, my core responsibilities include:

- Operating and programming CNC machines to produce precise parts and components.

- Interpreting engineering drawings and converting them into CNC programs.

- Setting up and adjusting machines, including tool selection, workpiece placement, and cutting parameters.

- Monitoring machine operation, detecting and resolving any issues.

- Maintaining a safe and clean work area, adhering to all safety regulations.

2. What types of CNC machines have you operated, and what are their capabilities?

I have extensive experience operating various types of CNC machines, including:

Milling Machines

- Horizontal and vertical milling machines for machining complex shapes and profiles.

- 5-axis milling machines for intricate and high-precision work.

Lathes

- CNC lathes for turning, drilling, and threading operations.

- CNC Swiss lathes for miniature and high-volume precision parts.

Other CNC Machines

- Wire EDM machines for intricate cuts and complex shapes.

- Plasma cutters for high-speed cutting of metal sheets.

3. What is your experience with CNC programming software?

I am proficient in using various CNC programming software, including:

- Mastercam and SolidCAM for CAD/CAM modeling and programming.

- GibbsCAM for complex 3D surface machining and toolpath generation.

- Siemens Sinumerik and Fanuc control systems for machine operation.

4. How do you ensure the accuracy and precision of CNC-machined parts?

I follow a rigorous process to ensure part accuracy and precision:

- Thoroughly inspect raw materials and cutting tools.

- Calibrate and maintain CNC machines regularly.

- Use high-quality measuring tools, such as calipers, micrometers, and CMMs, to verify dimensions and tolerances.

- Employ statistical process control (SPC) techniques to monitor and improve quality.

5. What are some common troubleshooting techniques you use for CNC machines?

My troubleshooting approach involves:

- Identifying error messages and consulting user manuals.

- Inspecting machine components, such as belts, bearings, and motors, for signs of wear or damage.

- Checking electrical connections and cables for loose or faulty connections.

- Analyzing toolpath and program parameters for potential errors.

- Consulting with colleagues or supervisors for additional support.

6. How do you stay updated with advancements in CNC technology?

I stay abreast of industry trends and developments through:

- Attending industry conferences and training workshops.

- Reading technical publications and online resources.

- Networking with other CNC professionals and industry experts.

7. What safety precautions do you observe when operating CNC machines?

Safety is paramount in my work, and I adhere to strict precautions:

- Wearing appropriate personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection.

- Ensuring proper machine guarding and interlocks are in place.

- Maintaining a clean and organized work area.

- Following established lockout/tagout procedures.

- Being aware of potential hazards and taking appropriate measures.

8. How do you handle multiple projects with different deadlines?

I effectively manage multiple projects by:

- Prioritizing tasks based on urgency and importance.

- Creating a detailed work schedule and sticking to it.

- Delegating tasks to colleagues when necessary.

- Communicating regularly with supervisors and team members to keep everyone informed and avoid delays.

9. What is your approach to continuous improvement in CNC operations?

I believe in continuous improvement and strive to:

- Identify areas for optimization in processes.

- Research and implement new technologies and techniques.

- Seek feedback from colleagues and supervisors for improvement suggestions.

- Document best practices and share knowledge with others.

10. How do you solve problems that arise during the machining process?

When faced with problems during machining, I follow a structured approach:

- Identify the root cause of the issue.

- Research and explore potential solutions.

- Consult with colleagues or supervisors for advice.

- Implement the appropriate solution.

- Monitor the results and make adjustments as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Numerical Control Operator (NC Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Numerical Control Operator (NC Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Numerical Control (NC) Operators play a vital role in manufacturing operations, ensuring efficient and precise production of components and products. Their key job responsibilities include:- Setting up and operating NC machines according to programmed instructions.

- Monitoring machine cycles and adjusting parameters for optimal performance.

- Identifying and troubleshooting operational issues promptly.

- Inspecting finished parts for dimensional accuracy and surface finish.

- Using measuring tools and equipment to ensure conformance to specifications.

- Reporting any deviations or defects to the supervisor promptly.

- Performing routine maintenance and lubrication on NC machines.

- Replacing worn-out tools and fixtures as needed.

- Ensuring proper tool alignment and calibration.

- Assisting in the planning and scheduling of production runs.

- Loading and unloading workpieces into and out of machines.

- Maintaining a clean and organized work area.

1. NC Machine Operation

2. Quality Control

3. Maintenance and Tooling

4. Production Planning and Scheduling

Interview Tips

To help candidates ace their interview for an NC Operator position, they can follow these tips:1. Technical knowledge and skills

2. Communication and teamwork

3. Safety and compliance

4. Continuous improvement and learning

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Numerical Control Operator (NC Operator) interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!