Feeling lost in a sea of interview questions? Landed that dream interview for Numerical Control Tool Programmer (NC Tool Programmer) but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Numerical Control Tool Programmer (NC Tool Programmer) interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

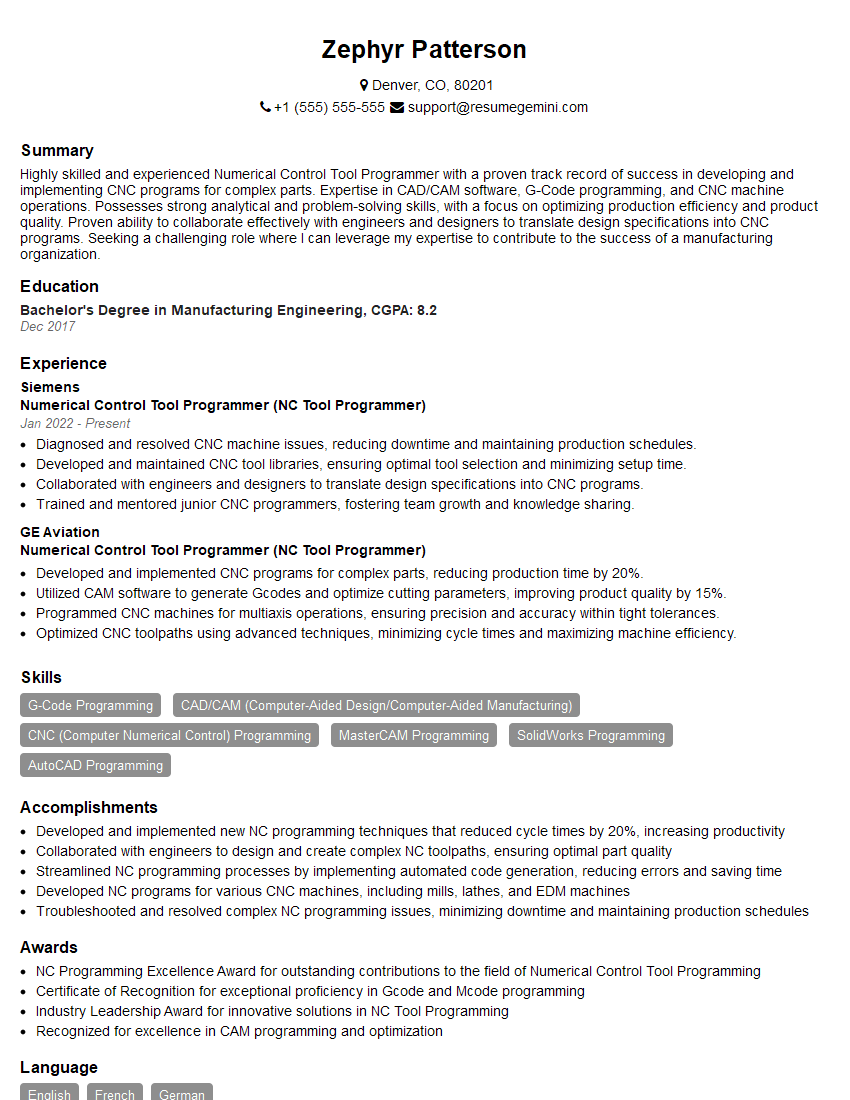

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Numerical Control Tool Programmer (NC Tool Programmer)

1. What are the main responsibilities of a Numerical Control Tool Programmer (NC Tool Programmer)?

As a Numerical Control Tool Programmer, my primary responsibilities revolve around developing, implementing, and maintaining numerical control (NC) programs for computer-controlled machine tools. These programs specify the precise movements, speeds, and tool changes required to produce complex parts and components.

2. Describe the different types of NC programming languages you are familiar with.

- G-code: Widely used in the CNC industry, known for its ability to control axis movements and other machine functions.

- APT (Automatically Programmed Tools): A high-level language designed specifically for NC programming, offering parametric programming capabilities.

- ISO code: An international standard for NC programming, provides a structured approach and enhanced portability of programs.

3. How do you approach optimizing NC programs for efficiency and accuracy?

- Analyze the part geometry and identify areas for optimization.

- Use appropriate cutting tools and toolpaths to minimize cycle times.

- Incorporate tool compensation techniques to ensure dimensional accuracy.

- Test and refine programs to eliminate errors and improve performance.

4. What are the key considerations when selecting cutting tools for NC programming?

- Material properties of the workpiece.

- Desired surface finish and tolerances.

- Machine capabilities and spindle speed.

- Cost and availability of cutting tools.

5. Explain the concept of coordinate systems in NC programming.

Coordinate systems establish the reference points and axes used to define the position and movement of the cutting tool. They include the machine coordinate system (MCS), workpiece coordinate system (WCS), and tool coordinate system (TCS). Understanding and manipulating these coordinate systems is essential for accurate programming.

6. How do you handle revisions and modifications to NC programs?

- Maintain clear documentation and version control to track changes.

- Identify and isolate the affected sections of the program.

- Implement the necessary modifications and conduct thorough testing.

- Communicate updates to relevant stakeholders.

7. Describe your experience in using simulation software to verify NC programs.

Simulation software allows me to virtually test NC programs before running them on actual machines. This helps identify potential errors, collisions, and inefficiencies early on. I have experience using software such as Vericut, NCSimul, and CATIA for simulation and optimization.

8. How do you stay updated on the latest advancements in NC programming and technology?

- Attend industry conferences and workshops.

- Read technical journals and online resources.

- Participate in online forums and discussion groups.

- Collaborate with colleagues and industry experts.

9. What are some common challenges you have encountered in NC programming and how did you overcome them?

- Troubleshooting complex geometries: Used advanced programming techniques and consulted with design engineers.

- Optimizing cycle times: Implemented efficient toolpaths and selected appropriate cutting parameters.

- Ensuring accuracy: Utilized tool compensation and conducted rigorous testing.

10. How would you approach programming an NC program for a complex multi-axis machine?

- Break down the geometry into manageable sections.

- Define appropriate coordinate systems and tool orientations.

- Utilize advanced programming features such as cutter compensation and canned cycles.

- Conduct thorough simulations and testing to verify program accuracy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Numerical Control Tool Programmer (NC Tool Programmer).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Numerical Control Tool Programmer (NC Tool Programmer)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Numerical Control Tool Programmers (NC Tool Programmers) are skilled professionals responsible for developing, implementing, and maintaining numerical control (NC) programs for computer-controlled machine tools. These programs guide the machines through complex manufacturing processes, ensuring precise and efficient production of various components and parts.

1. Program Development

NC Tool Programmers analyze engineering drawings and specifications to create NC programs that instruct machine tools in performing specific operations. These programs involve calculating cutting paths, feed rates, and spindle speeds to optimize machining processes.

2. Machine Setup and Operation

They set up and operate NC machines, loading tools, fixtures, and workpieces. They ensure that machines are calibrated and running smoothly, and monitor operations to identify and correct any issues.

3. Quality Control

NC Tool Programmers inspect and measure machined parts to ensure they meet specifications and quality standards. They make adjustments to programs or machine settings as necessary to maintain accuracy and precision.

4. Process Optimization

They continuously review and optimize NC programs to improve efficiency and reduce production time. They identify areas for improvement and develop new methods to enhance productivity.

5. Maintenance and Troubleshooting

NC Tool Programmers perform routine maintenance on NC machines and troubleshoot any issues that may arise. They diagnose problems and make repairs or adjustments to ensure machines are operating at peak performance.

Interview Tips

Preparing for an NC Tool Programmer interview requires a combination of technical knowledge and interview skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry. Research the specific position you are applying for to understand its key responsibilities and expectations.

2. Review NC Programming and Manufacturing Principles

Brush up on your knowledge of NC programming languages, such as G-code and CNC. Review fundamental manufacturing principles, including machining processes, cutting tools, and materials.

3. Highlight Your Programming Skills

Emphasize your experience in developing and implementing NC programs for different types of machine tools. Showcase your proficiency in optimizing programs for efficiency and accuracy.

4. Demonstrate Problem-Solving Abilities

Interviewers may ask questions to assess your problem-solving skills. Be prepared to discuss how you troubleshoot and resolve issues with NC machines and programs.

5. Be Confident and Articulate

Convey your confidence in your abilities and be articulate in describing your experience. Clearly explain your technical skills and how you can apply them to the role.

6. Practice Common Interview Questions

Prepare for common interview questions related to NC programming, manufacturing, and your qualifications. Anticipate questions about your experience, technical expertise, and problem-solving approach.

7. Prepare Questions for the Interviewer

Asking well-informed questions at the end of the interview demonstrates your interest and engagement. Questions about the company’s manufacturing processes, future projects, or growth opportunities can be effective.

8. Dress Professionally and Arrive on Time

Make a good first impression by dressing professionally and arriving on time for your interview. Show respect for the interviewer and the opportunity.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Numerical Control Tool Programmer (NC Tool Programmer) role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.