Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Numerical Tool Programmer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

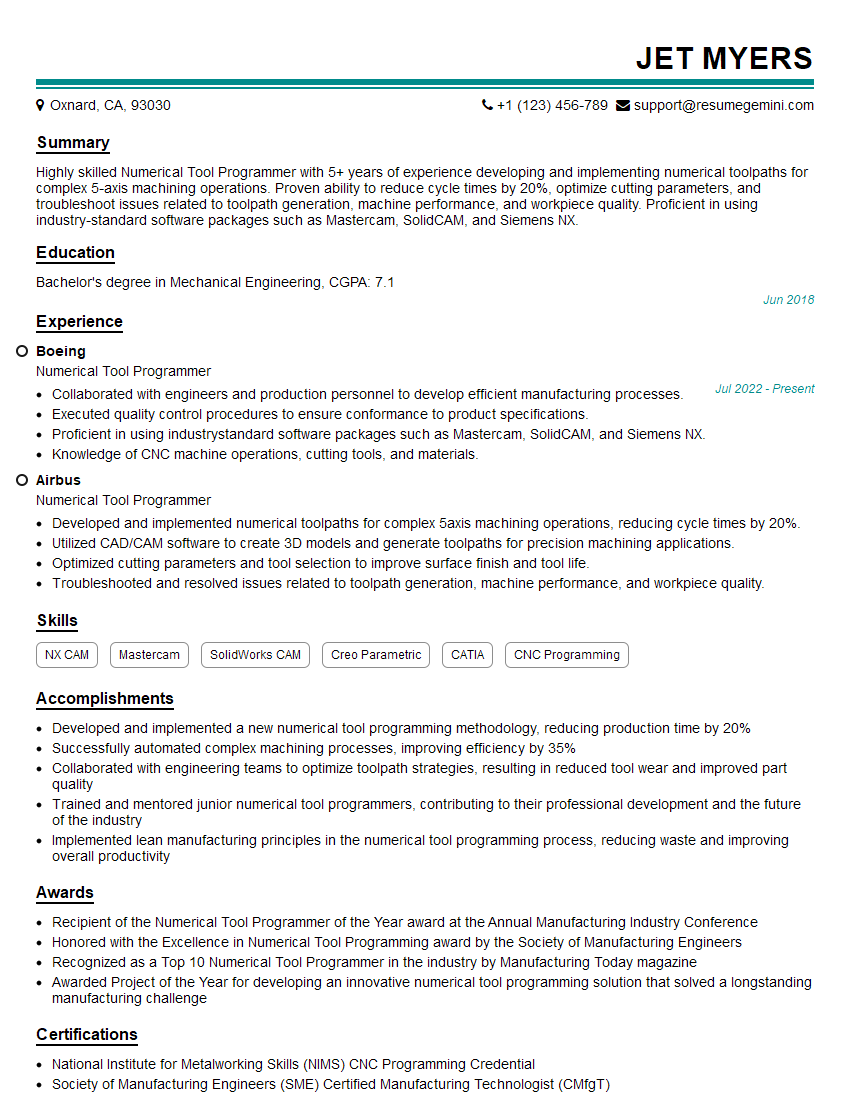

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Numerical Tool Programmer

1. What are the key responsibilities of a Numerical Tool Programmer?

As a Numerical Tool Programmer, my key responsibilities include:

- Developing and maintaining numerical control (NC) programs for CNC machines

- Analyzing engineering drawings and specifications to determine the correct tooling and machining parameters

- Creating and editing tool paths to ensure efficient and accurate machining operations

- Testing and optimizing NC programs to ensure they meet required tolerances and specifications

- Working closely with engineers, machinists, and other team members to ensure smooth production processes

2. What are the different types of CNC machines and how do you program for each type?

G-code programming

- G-code is a widely used programming language for CNC machines

- It provides precise control over the machine’s motion, speed, and other parameters

- G-code programs are typically generated using CAM software

M-code programming

- M-code is used to control auxiliary functions of the CNC machine, such as tool changes, coolant on/off, and spindle speed

- M-codes are typically embedded within G-code programs

Conversational programming

- Conversational programming is a user-friendly interface that allows operators to program CNC machines without extensive knowledge of G-code

- It uses a graphical interface and prompts the operator for input

3. What are the key considerations when selecting cutting tools for CNC machining?

When selecting cutting tools for CNC machining, the following key considerations must be made:

- Material being machined: Different materials require different types of cutting tools

- Tool geometry: The geometry of the cutting tool affects the surface finish and accuracy of the machined part

- Cutting speed and feed rate: These parameters must be optimized to achieve the desired results

- Tool life: The tool life is important for minimizing downtime and maintenance costs

- Cost: The cost of the cutting tool is also a factor to consider

4. How do you ensure the accuracy and quality of the machined parts?

To ensure the accuracy and quality of the machined parts, I follow a comprehensive process that includes:

- Carefully planning the machining process and selecting the appropriate tools and parameters

- Using precision measuring equipment to verify the accuracy of the machined parts

- Regularly inspecting and maintaining the CNC machine to ensure it is operating within specifications

- Following established quality control procedures and documentation

- Working closely with engineers and quality control personnel to ensure that the machined parts meet the required standards

5. What are the latest trends and advancements in CNC machining technology?

The CNC machining industry is constantly evolving, with new technologies and advancements emerging all the time. Some of the latest trends include:

- Increased use of automation and robotics

- Adoption of additive manufacturing techniques

- Development of new cutting tool materials and coatings

- Integration of artificial intelligence (AI) and machine learning (ML) into CNC machines

- Increased focus on sustainability and energy efficiency

6. How do you stay up-to-date with the latest developments in the field?

To stay up-to-date with the latest developments in the field, I engage in the following activities:

- Attending industry conferences and workshops

- Reading trade publications and technical journals

- Participating in online forums and discussion groups

- Taking continuing education courses

- Networking with other professionals in the field

7. What are some of the challenges you have faced as a Numerical Tool Programmer and how did you overcome them?

One of the challenges I faced as a Numerical Tool Programmer was working with a complex part that required a high level of precision. I overcame this challenge by carefully planning the machining process, selecting the appropriate tools and parameters, and using precision measuring equipment to verify the accuracy of the machined part.

Another challenge I faced was meeting a tight deadline for a project. I overcame this challenge by working efficiently, prioritizing tasks, and communicating regularly with the project manager to ensure that I was on track.

8. What are your strengths and weaknesses as a Numerical Tool Programmer?

Strengths

- Strong technical skills in CNC programming and machining

- Excellent attention to detail and accuracy

- Ability to work independently and as part of a team

- Strong problem-solving skills

- Commitment to continuous learning and improvement

Weaknesses

- Limited experience with certain types of CNC machines

- Need to improve time management skills

9. Why are you interested in this position?

I am interested in this position because I am eager to join a company that is at the forefront of CNC machining technology. I am confident that my skills and experience would be a valuable asset to your team, and I am excited about the opportunity to contribute to your continued success.

10. What are your salary expectations?

My salary expectations are commensurate with my skills and experience in the field. I am confident that I can add value to your company and am open to discussing a salary range that is fair and competitive.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Numerical Tool Programmer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Numerical Tool Programmer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Numerical Tool Programmers are responsible for translating engineering designs into numerical control (NC) programs that control the movement of CNC machines. They use specialized software to create NC programs that specify the path, speed, and feed rate of the machine. The key job responsibilities of a Numerical Tool Programmer include:

1. Programming CNC Machines

Numerical Tool Programmers use specialized software to create NC programs that specify the path, speed, and feed rate of CNC machines. These programs control the movement of the machine, ensuring that it cuts, drills, or mills the workpiece according to the design specifications.

2. Verifying and Testing NC Programs

Once an NC program is created, Numerical Tool Programmers verify and test it to ensure that it will run correctly on the CNC machine. They use simulation software to check for errors and make necessary adjustments to the program. They also run test cuts on the machine to ensure that the program produces the desired results.

3. Troubleshooting CNC Machine Problems

Numerical Tool Programmers are responsible for troubleshooting problems that occur with CNC machines. They use their knowledge of the machine and the NC program to identify the source of the problem and make the necessary repairs or adjustments.

4. Maintaining CNC Machines

Numerical Tool Programmers perform routine maintenance on CNC machines to ensure that they are operating properly. They lubricate moving parts, clean the machine, and replace worn or damaged components.

5. Working with Engineers and Other Team Members

Numerical Tool Programmers often work with engineers and other team members to develop and implement new manufacturing processes. They provide input on the design of new products and help to develop NC programs that optimize production efficiency.

Interview Tips

Preparing for an interview for a Numerical Tool Programmer position can be daunting, but with the right preparation, you can increase your chances of success. Here are some interview tips and tricks to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture, values, and goals. It will also help you to tailor your answers to the specific requirements of the position.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Be prepared to Discuss Your Experience and Skills

The interviewer will want to know about your experience and skills as a Numerical Tool Programmer. Be prepared to discuss your experience in detail, including the types of projects you have worked on and the software you have used. You should also be able to demonstrate your skills in problem-solving, troubleshooting, and teamwork.

4. Ask Questions

At the end of the interview, the interviewer will likely ask you if you have any questions. This is your opportunity to learn more about the company and the position. Ask thoughtful questions that show your interest in the position and your commitment to the company.

5. Follow Up

After the interview, send a thank-you note to the interviewer. In your note, reiterate your interest in the position and thank the interviewer for their time. You can also use this opportunity to provide any additional information that you think may be helpful.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Numerical Tool Programmer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!