Are you gearing up for an interview for a Nut Sheller Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Nut Sheller Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

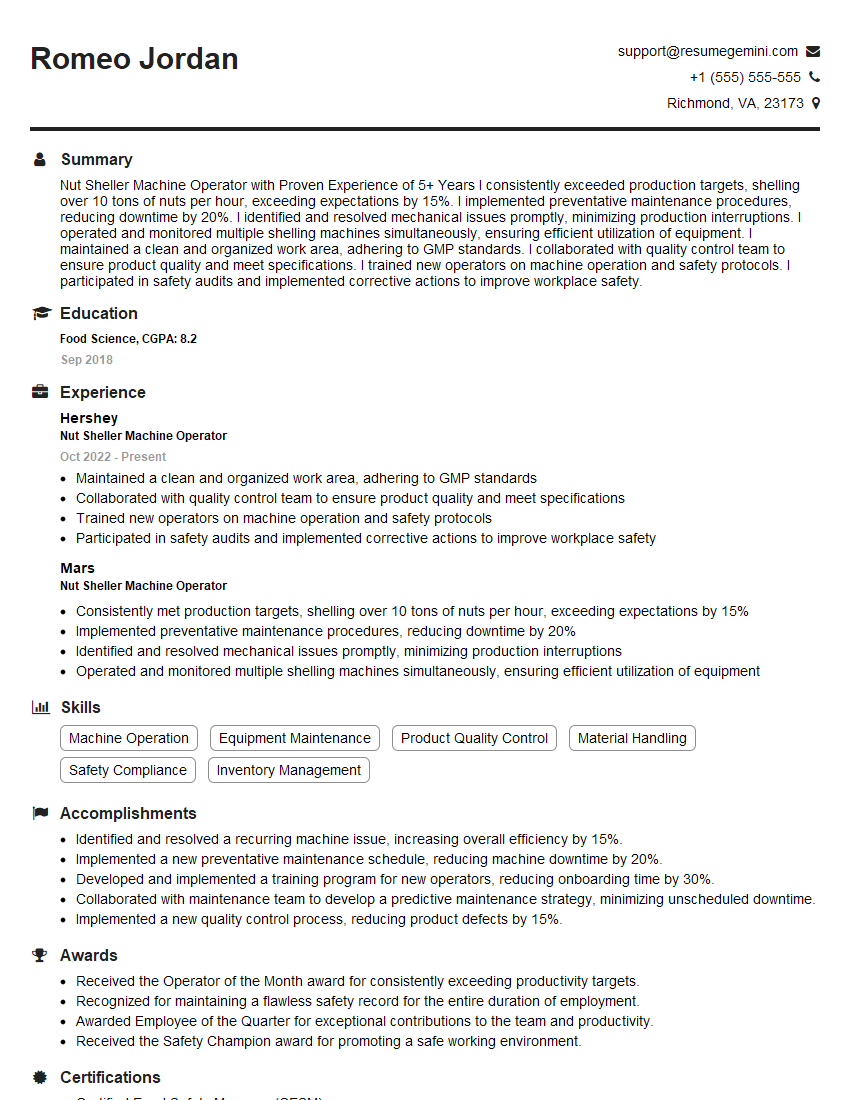

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nut Sheller Machine Operator

1. What are the different types of nut shellers and their applications?

There are several types of nut shellers, each designed for specific types of nuts and applications. Some common types include:

- Drum Shellers: Used for high-volume shelling of large nuts like walnuts, almonds, and pecans. They consist of a rotating drum with internal beaters that break the nutshells.

- Impact Shellers: Designed for smaller nuts like pistachios and hazelnuts. They use impact forces to crack open the shells.

- Roller Shellers: Use rotating rollers to crush and separate the shells from the kernels. Suitable for soft-shelled nuts like chestnuts and hazelnuts.

- Air-Suction Shellers: Utilize a combination of air pressure and suction to remove shells from nuts. Ideal for delicate nuts like cashews.

- Hammer Mills: Heavy-duty machines used for large-scale industrial shelling of nuts like almonds and walnuts. They use hammers or blades to break open the shells.

2. Describe the process of nut shelling, including safety precautions.

Pre-Shelling:

- Inspect nuts for foreign objects and remove any debris.

- Calibrate the sheller to suit the specific nut type and size.

Shelling:

- Feed nuts into the sheller’s hopper or conveyor belt.

- The sheller’s mechanism will break open the shells and separate the kernels from the shells.

Post-Shelling:

- Remove shelled kernels from the machine.

- Inspect and sort kernels to remove any remaining shell fragments or impurities.

Safety Precautions:

- Wear appropriate safety gear, including gloves, eye protection, and hearing protection.

- Keep hands away from moving parts of the sheller.

- Ensure proper ventilation to prevent dust buildup.

- Follow manufacturer’s instructions for safe operation and maintenance.

3. How do you troubleshoot common problems with nut shellers?

- Low shelling efficiency: Check for dull or damaged blades/beaters, incorrect calibration, or insufficient nut feed.

- Kernel damage: Adjust shelling parameters (e.g., speed, pressure), inspect for worn-out components, or ensure nuts are free of moisture.

- Excessive noise: Lubricate moving parts, check for loose components, or replace worn bearings.

- Overheating: Check for proper ventilation, inspect motor for overheating, or clean accumulated debris.

- Vibration: Balance the sheller’s rotating components, check for loose bolts or misalignment.

4. What are the quality control measures you implement to ensure the production of high-quality shelled nuts?

- Raw Material Inspection: Check incoming nuts for quality, size, and foreign objects.

- Regular Machine Calibration: Ensure optimal shelling efficiency and prevent kernel damage.

- Kernel Inspection: Visually inspect shelled kernels for shell fragments, impurities, or discoloration.

- Sampling and Testing: Conduct random sampling to test kernel quality, moisture content, and adherence to standards.

- Process Monitoring: Track shelling parameters (e.g., speed, pressure) and adjust as needed.

5. How do you maintain a nut sheller to ensure optimal performance?

- Regular Cleaning: Remove dust, debris, and nut residues to prevent clogging and wear.

- Lubrication: Lubricate moving parts according to manufacturer’s recommendations.

- Blade/Beater Inspection: Inspect blades or beaters for sharpness and replace when necessary.

- Bearing Replacement: Replace worn or damaged bearings to prevent excessive vibration.

- Conveyor Maintenance: Ensure conveyor belts are clean, tensioned properly, and free of damage.

6. What is the importance of maintaining a clean and sanitary work environment in a nut shelling operation?

- Product Quality: Prevents contamination of shelled nuts with bacteria, insects, or foreign objects.

- Equipment Longevity: Reduces wear and tear on machinery by minimizing dust and debris buildup.

- Worker Safety: Ensures a healthy and safe work environment for employees.

- Regulatory Compliance: Meets industry standards and food safety regulations.

- Customer Satisfaction: Provides customers with high-quality, sanitary nuts.

7. How do you handle and store shelled nuts to maintain their quality and freshness?

- Proper Packaging: Use airtight containers or bags to prevent moisture loss and oxidation.

- Temperature Control: Store nuts in cool, dry environments (ideally refrigerated) to slow down spoilage.

- Pest Control: Implement measures to prevent pests from contaminating stored nuts.

- First-In, First-Out (FIFO): Rotate inventory to ensure older nuts are used first.

- Quality Monitoring: Regularly inspect stored nuts for signs of spoilage or deterioration.

8. What is your understanding of the different grades of shelled nuts?

- Whole Kernels: Intact kernels with no major defects.

- Halves: Broken kernels that are at least 50% of a whole kernel.

- Pieces: Broken kernels that are less than 50% of a whole kernel.

- Small Pieces: Very small fragments of kernels.

- Grading Standards: Different industries and markets have specific grading standards for the size, quality, and cleanliness of shelled nuts.

9. Explain how you would train a new employee to operate a nut sheller safely and efficiently.

- Safety Orientation: Review safety protocols, machine hazards, and personal protective equipment.

- Machine Familiarization: Demonstrate the different components of the sheller and explain their functions.

- Calibration and Adjustment: Show the employee how to calibrate the machine for different nut types and sizes.

- Operation Procedures: Guide the employee through the startup, shutdown, and emergency stop procedures.

- Troubleshooting: Provide guidance on identifying and resolving common issues with the sheller.

- Quality Control: Train the employee on kernel inspection techniques and quality standards.

- Supervision and Evaluation: Observe the employee’s performance and provide feedback to ensure proper operation.

10. Can you describe the maintenance procedures you would follow to keep a nut sheller running smoothly?

- Daily Checks: Visually inspect the machine for any damage, loose parts, or unusual noises.

- Weekly Cleaning: Remove dust, debris, and nut residues from all surfaces of the sheller.

- Monthly Lubrication: Lubricate moving parts according to the manufacturer’s recommendations.

- Quarterly Inspections: Check for wear and tear on blades, beaters, and other critical components.

- Annual Maintenance: Conduct a thorough inspection and overhaul of the machine, including cleaning, lubrication, and replacement of worn parts.

- Records: Maintain detailed records of all maintenance activities for future reference and compliance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nut Sheller Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nut Sheller Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nut Sheller Machine Operators are responsible for the efficient and safe operation of nut shelling machines in the food processing industry. They ensure that the machines are operating smoothly, that nuts are being shelled properly, and that the finished product meets quality standards.

1. Machine Operation and Maintenance

Operate nut shelling machines to remove shells from various types of nuts, including almonds, walnuts, and pistachios.

- Monitor machine settings, such as speed, temperature, and pressure, to optimize shelling efficiency.

- Perform routine maintenance and cleaning of machines to ensure proper functioning and prevent breakdowns.

2. Quality Control and Inspection

Inspect shelled nuts for quality, ensuring they meet size, color, and moisture specifications.

- Remove defective or damaged nuts from the production line.

- Maintain detailed records of inspections to track quality and identify potential issues.

3. Production Monitoring and Reporting

Monitor production output and maintain records of machine performance and downtime.

- Identify and address bottlenecks in the shelling process to increase efficiency.

- Provide timely reports to supervisors on production status and any issues encountered.

4. Safety and Compliance

Follow established safety protocols and wear appropriate personal protective equipment (PPE).

- Operate machines in accordance with manufacturer guidelines and industry best practices.

- Maintain a clean and organized work area to prevent accidents and contamination.

Interview Tips

To ace the interview for a Nut Sheller Machine Operator position, candidates should prepare thoroughly and demonstrate their understanding of the role’s responsibilities and skills.

1. Research the Role and Company

Familiarize yourself with the job description and research the company’s operations to gain a deeper understanding of the position and industry.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on the latest trends.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating nut shelling machines, including any specific training or certifications you hold.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Be prepared to discuss your approach to quality control and safety.

3. Demonstrate Problem-Solving Abilities

Nut Sheller Machine Operators may encounter unexpected challenges, so interviewers often seek candidates with strong problem-solving skills.

- Share examples of how you have identified and resolved machine malfunctions or production issues.

- Discuss your approach to troubleshooting and finding solutions efficiently.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company.

- Inquire about the company’s growth plans and industry outlook.

- Ask about opportunities for professional development and advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nut Sheller Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!