Are you gearing up for an interview for a Nut Tightener position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Nut Tightener and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

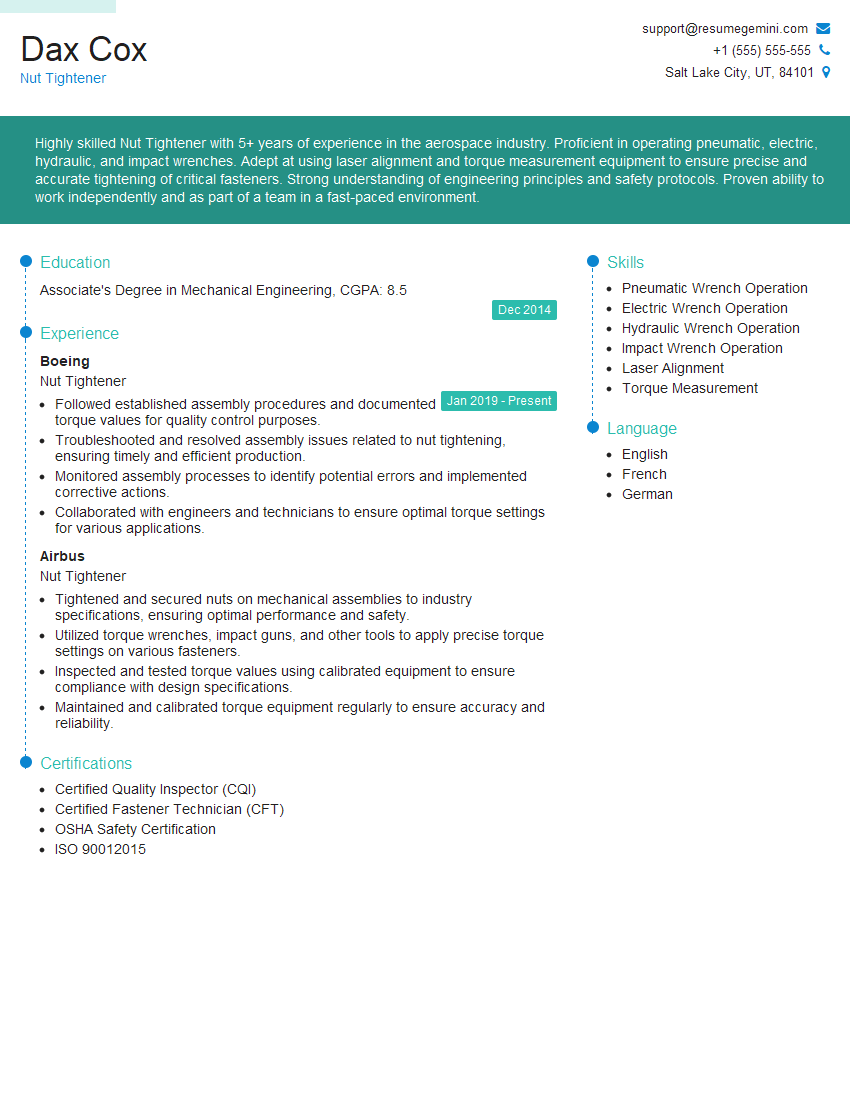

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nut Tightener

1. Explain the different types of nut tightening tools and their applications?

There are various types of nut tightening tools, each designed for specific applications. Here are some common types:

- Manual Nut Runners: These are handheld tools that require manual force to tighten nuts. They include wrenches, sockets, and spanners.

- Electric Nut Runners: These tools use an electric motor to power the tightening process. They are more efficient and faster than manual tools.

- Pneumatic Nut Runners: These tools use compressed air to generate power for tightening nuts. They are more powerful than electric tools but require an external air supply.

- Hydraulic Nut Runners: These tools use hydraulic pressure to tighten nuts. They are the most powerful and commonly used in industrial applications.

2. What are the key factors to consider when selecting a nut tightening tool?

Factors to consider:

- Torque requirements: The tool should be able to apply the required torque to tighten the nuts securely.

- Speed: The tool should tighten nuts at an acceptable speed to meet production targets.

- Accuracy: The tool should tighten nuts within the specified torque range to ensure proper operation.

- Ergonomics: The tool should be comfortable to use and reduce fatigue for prolonged periods.

- Durability: The tool should be durable enough to withstand the demands of the application and provide long-term reliability.

3. Describe the process of tightening a nut to the correct torque specification?

To tighten a nut to the correct torque specification, follow these steps:

- Choose the appropriate tool: Select a nut tightening tool that meets the required torque and speed specifications.

- Set the torque: Adjust the tool to the desired torque setting using the manufacturer’s instructions.

- Clean the nut and bolt: Remove any dirt or debris from the nut and bolt to ensure proper contact.

- Lubricate the threads: Apply a thin layer of lubricant to the bolt threads to reduce friction and ensure even torque distribution.

- Tighten the nut: Hold the tool perpendicular to the nut and gradually apply force until the desired torque is reached.

- Verify the torque: Use a torque wrench or torque indicator to verify that the nut has been tightened to the correct specification.

4. What are the potential consequences of over-tightening or under-tightening a nut?

Over-tightening:

- Damage to the nut or bolt: Excessive torque can strip or damage the threads, weakening the joint.

- Elongation of the bolt: Over-tightening can stretch the bolt, reducing its load-bearing capacity.

Under-tightening:

- Loose joint: A nut that is not tightened sufficiently may become loose, potentially leading to equipment failure.

- Vibration and noise: A loose nut can cause vibration and noise during operation, which can be a safety hazard.

5. What are the safety precautions to take when using nut tightening tools?

- Wear appropriate PPE: Wear safety glasses, gloves, and ear protection when operating nut tightening tools.

- Inspect the tool: Check the tool for any damage or defects before use.

- Use the correct tool: Use a nut tightening tool that is rated for the required torque and speed.

- Maintain a firm grip: Hold the tool securely and maintain a stable position when tightening nuts.

- Avoid loose clothing: Ensure that loose clothing or jewelry does not get caught in the tool.

6. What types of maintenance are required for nut tightening tools?

- Regular cleaning: Clean the tool after each use to remove dirt and debris.

- Lubrication: Lubricate moving parts according to the manufacturer’s instructions.

- Calibration: Calibrate the tool periodically using a torque wrench or torque indicator to ensure accuracy.

- Inspection: Inspect the tool regularly for any signs of wear or damage.

- Repair: Seek professional repair if the tool is damaged or malfunctioning.

7. What are some common troubleshooting tips for nut tightening tools?

- Tool not tightening nuts: Check the torque setting, power supply, and condition of the tool.

- Nuts coming loose: Verify the torque setting, check for stripped threads, and ensure proper lubrication.

- Tool overheating: Allow the tool to cool down, check lubrication, and inspect for any obstructions.

- Tool making excessive noise: Check the condition of the bearings, gears, and moving parts.

- Tool leaking: Identify the source of the leak, replace seals or gaskets as needed.

8. Describe your experience in using nut tightening tools in a work or project setting.

In my previous role at [Company Name], I was responsible for assembling and maintaining critical machinery. I used various nut tightening tools, including manual, electric, and pneumatic, to ensure proper fastening and torque specifications. I have experience in selecting the appropriate tool for the application, setting torque levels accurately, and maintaining the tools regularly.

9. How do you stay up-to-date with the latest developments in nut tightening technology?

- Industry publications: I read trade magazines and journals to stay informed about new tools and techniques.

- Online resources: I utilize online forums and technical websites to access up-to-date information.

- Manufacturer’s updates: I subscribe to newsletters and technical bulletins from tool manufacturers to receive updates on their products.

- Conferences and workshops: I attend industry conferences and workshops to learn about advancements and best practices.

10. Why are you interested in this Nut Tightener position with our company?

I am eager to join your company as a Nut Tightener because I am highly skilled and experienced in this field. I am confident that I can contribute to your team by ensuring the accurate and efficient fastening of critical components. I am also committed to maintaining high standards of safety and quality in my work.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nut Tightener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nut Tightener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Nut Tighteners, also known as Production Assemblers, play a pivotal role in manufacturing and assembly processes by ensuring that nuts are tightened securely to the required specifications. Their primary tasks focus on operating and maintaining machinery used for tightening nuts, as well as performing manual assembly tasks as needed.

1. Machine Operation and Maintenance

Operate nut tightening machinery, ensuring accurate and consistent tightening of nuts to meet quality standards.

- Calibrate and adjust machines to achieve optimal tightening torque and tension.

- Monitor machines for any malfunctions or irregularities, and perform basic maintenance tasks to keep them in good working order.

2. Material Handling

Handle and move materials, including nuts, bolts, and other components, safely and efficiently.

- Load and unload materials from machines and conveyors.

- Inspect materials for any defects or damage before tightening.

3. Quality Control

Inspect and verify that nuts are tightened correctly, meeting both product and industry standards.

- Use measuring tools to ensure that nuts meet specified torque and tension requirements.

- Identify and rectify any errors or defects in the tightening process.

4. Safety and Compliance

Adhere to safety regulations and guidelines to ensure a safe working environment.

- Wear appropriate safety gear, including gloves, goggles, and earplugs.

- Follow established procedures for handling and storing hazardous materials.

Interview Tips

Preparing for a Nut Tightener interview requires a combination of technical knowledge and an understanding of the hiring manager’s expectations. Here are some tips to help you ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing. Understand the specific responsibilities of the Nut Tightener role and how it aligns with your skills and experience.

- Visit the company’s website.

- Read industry publications and news articles.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in operating nut tightening machinery, as well as your experience in materials handling and quality control. Quantify your accomplishments whenever possible, using specific examples to demonstrate your abilities.

- “I consistently achieved a 99% accuracy rate in tightening nuts to the required torque specifications.”

- “I developed and implemented a new procedure for inspecting nuts for defects, which reduced the rejection rate by 15%.”

3. Demonstrate Safety Consciousness

Safety is paramount in manufacturing environments. Highlight your understanding of safety protocols and your commitment to following them. Mention any relevant certifications or training you have completed.

- “I am OSHA-certified in machine safety and hazardous materials handling.”

- “I consistently wear appropriate safety gear and follow all established safety procedures.”

4. Be Prepared for Technical Questions

Expect questions about your knowledge of nut tightening machines, including their operation, maintenance, and calibration. You may also be asked about your understanding of quality control techniques and industry standards.

- “Explain the different types of nut tightening machines and their applications.”

- “Describe the steps involved in calibrating a nut tightening machine.”

5. Practice Your Answers

Rehearse your answers to common interview questions to build confidence and deliver clear and concise responses. Consider using the STAR method (Situation, Task, Action, Result) to структурировать your answers and highlight your skills.

- Example: “Tell me about a time you faced a challenge in tightening nuts.” (STAR method)

- Situation: “I was working on a large assembly project with a tight deadline.”

- Task: “I needed to tighten a large number of nuts to precise specifications.”

- Action: “I carefully calibrated the nut tightening machine and used a torque wrench to ensure accuracy.”

- Result: “I completed the task on time and to the required standards, contributing to the successful completion of the project.”

Next Step:

Now that you’re armed with the knowledge of Nut Tightener interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Nut Tightener positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini