Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Nylon Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

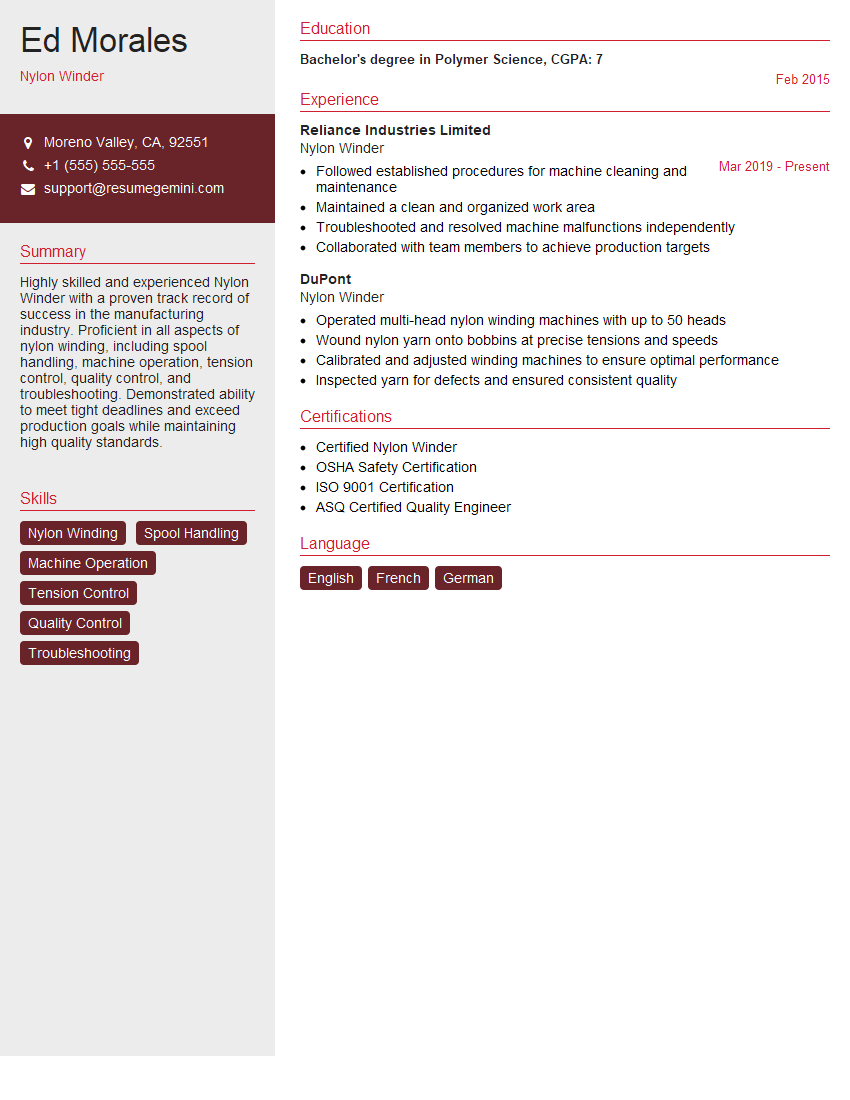

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Nylon Winder

1. Describe the process of winding nylon onto a bobbin?

- The first step is to select the correct nylon thread and bobbin for the job.

- Next, the nylon thread is passed through the tensioning device and wound onto the bobbin.

- The winding speed, tension, and traversing motion must be carefully controlled to ensure a uniform and evenly wound bobbin.

2. What are the different types of nylon winding machines available?

Automatic winding machines

- Fully automated machines that can handle large volumes of nylon thread.

- These machines are typically used in commercial and industrial settings.

Semi-automatic winding machines

- Require some manual operation, such as loading the nylon thread and starting the winding process.

- These machines are often used in smaller-scale operations or for specialized winding applications.

Manual winding machines

- Require the operator to manually wind the nylon thread onto the bobbin.

- These machines are typically used for small-scale or hobbyist applications.

3. What are the key factors that affect the quality of the wound nylon bobbins?

- The quality of the nylon thread

- The condition of the bobbin

- The winding speed and tension

- The traversing motion of the winding machine

- The operator’s skill and experience

4. How do you troubleshoot common problems that can occur during nylon winding?

- Nylon thread breakage

- Uneven winding

- Bobbin vibration

- Machine overheating

5. How do you ensure that the wound nylon bobbins meet the required specifications?

- Regularly calibrate the winding machine

- Inspect the wound bobbins for defects

- Test the wound bobbins to ensure they meet the required specifications

6. What safety precautions should be taken when operating a nylon winding machine?

- Wear appropriate safety gear, such as gloves and safety glasses.

- Keep the work area clean and free of debris.

- Be aware of the moving parts of the machine and keep hands and clothing away from them.

- Follow the manufacturer’s instructions for safe operation and maintenance.

7. What are the different types of nylon thread used in winding?

- Monofilament nylon

- Multifilament nylon

- Textured nylon

8. What are the different applications of nylon wound bobbins?

- Textile industry

- Fishing industry

- Construction industry

- Automotive industry

9. What are the advantages of using nylon wound bobbins over other types of bobbins?

- High strength and durability

- Resistance to abrasion and chemicals

- Lightweight and easy to handle

- Low moisture absorption

10. What are the latest trends in nylon winding technology?

- Increased automation

- Improved winding speed and efficiency

- Development of new nylon materials with enhanced properties

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Nylon Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Nylon Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Nylon Winder plays a crucial role in the manufacturing process of nylon products, operating advanced machinery to produce high-quality nylon threads and materials.

1. Operating Nylon Winding Machines

Expertly operate and maintain nylon winding machines, ensuring efficient and continuous production.

- Monitor machine parameters and adjust settings for optimal performance.

- Load and unload nylon spools, ensuring proper alignment and tension.

2. Quality Control and Inspection

Conduct thorough quality checks on nylon threads and materials, adhering to established standards.

- Inspect nylon threads for defects, breaks, or inconsistencies using visual inspection and measuring tools.

- Maintain detailed records and document any quality issues for further analysis and improvement.

3. Maintenance and Troubleshooting

Proactively maintain and troubleshoot nylon winding machines to minimize downtime and ensure smooth operations.

- Perform regular maintenance tasks, such as cleaning, lubrication, and calibration.

- Quickly identify and resolve machine malfunctions, minimizing production disruptions.

4. Material Handling and Inventory Management

Efficiently manage nylon materials and inventory to ensure seamless production.

- Receive and store nylon materials according to established procedures.

- Monitor inventory levels and replenish supplies as needed to prevent shortages.

Interview Tips

Preparing thoroughly for an interview is crucial. Here are some tips to help you ace your interview for a Nylon Winder position:

1. Research the Company and Position

Demonstrate your interest and knowledge by researching the company’s background, industry, and the specific Nylon Winder position.

- Visit the company’s website, social media pages, and industry publications.

- Identify the company’s mission, values, and products or services.

2. Practice Your Answers to Common Interview Questions

Prepare answers to typical interview questions related to your skills and experience as a Nylon Winder.

- Describe your experience in operating nylon winding machines and maintaining quality standards.

- Share an example of a time you successfully resolved a machine malfunction.

3. Highlight Your Technical Skills

Emphasize your proficiency in nylon winding techniques, machine operation, and quality control procedures.

- Showcase your knowledge of different types of nylon materials and their properties.

- Describe your ability to use measuring tools and inspection equipment.

4. Show Your Passion for Manufacturing

Express your enthusiasm for working in a manufacturing environment and your commitment to producing high-quality products.

- Share examples of how you have contributed to efficiency improvements or quality enhancements.

- Explain why you are interested in the Nylon Winder position specifically.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Nylon Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!