Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oakes Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

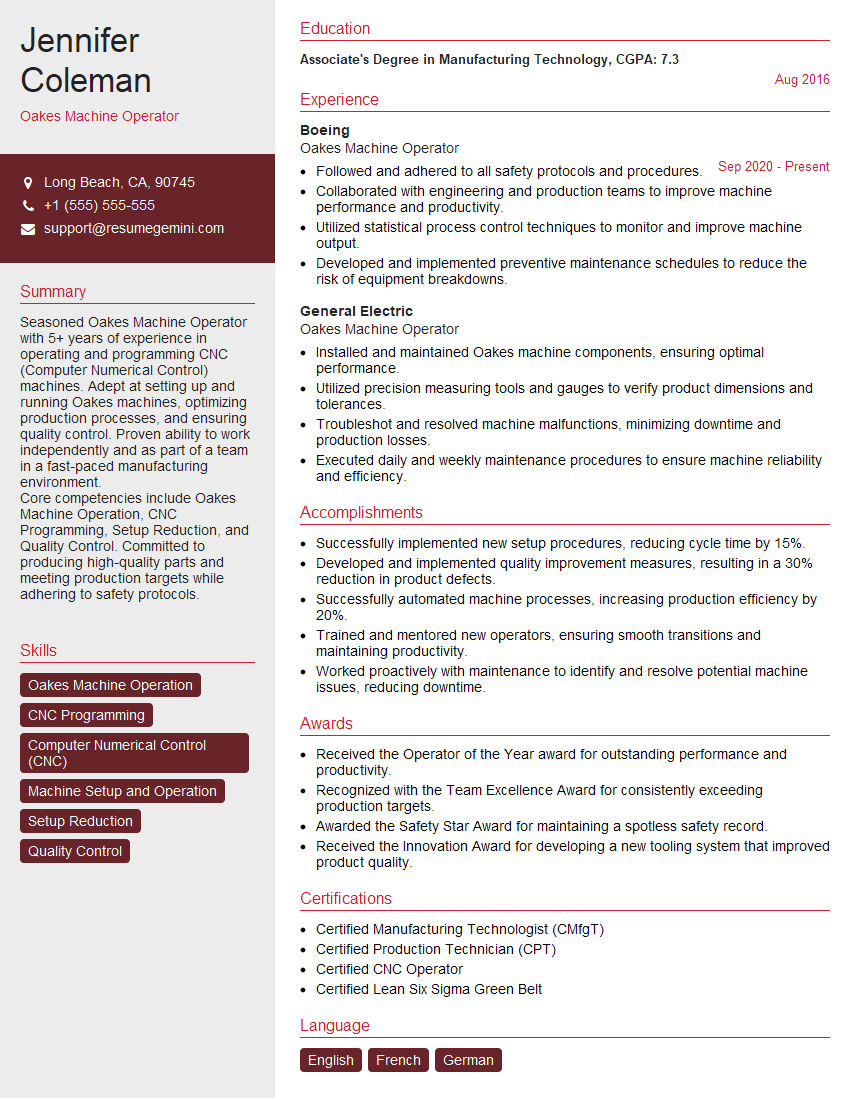

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oakes Machine Operator

1. Describe the process of setting up and operating an Oakes machine?

Sample Answer:

- Ensure the machine is properly calibrated and secured.

- Install the correct tooling and fixtures.

- Properly load the workpiece into the machine.

- Set the machine parameters (speed, feed, depth of cut).

- Initiate the machining process and monitor its progress.

- Unclamp and remove the finished workpiece from the machine.

2. Explain the different cutting tools used for Oakes machines and when each type is appropriate?

Types of Cutting Tools

- Turning Tools: Used for creating cylindrical shapes.

- Boring Tools: For enlarging existing holes or creating new ones.

- Facing Tools: For creating flat surfaces on the workpiece.

- Grooving Tools: To create grooves or channels on the workpiece.

Appropriate Applications

- Depending on the material and desired accuracy.

- For specific cuts, such as roughing or finishing operations.

- Based on tool geometry, which influences the chip formation and surface finish.

3. How do you maintain and troubleshoot an Oakes machine?

Sample Answer:

- Regularly clean and lubricate the machine components.

- Check for loose connections or worn parts.

- Inspect the cutting tools for wear or damage.

- Monitor the machine’s performance and identify any unusual noises or vibrations.

- Troubleshoot common issues, such as tool breakage, workpiece distortion, or control system errors.

4. Describe the safety precautions you take when operating an Oakes machine?

Sample Answer:

- Wear appropriate safety gear (safety glasses, gloves, earplugs).

- Ensure the machine is properly guarded.

- Never operate the machine with loose clothing or jewelry.

- Keep the work area clean and free of debris.

- Follow lockout/tagout procedures when servicing the machine.

5. What types of materials can be processed on an Oakes machine?

Sample Answer:

- Metals: Steel, aluminum, brass, copper

- Plastics

- Composite materials

- Wood

- Ceramics

6. Explain the difference between roughing and finishing cuts?

Roughing Cuts

- Remove excess material quickly.

- Use higher feed rates and depths of cut.

- Result in a rougher surface finish.

Finishing Cuts

- Refine the surface finish.

- Use lower feed rates and depths of cut.

- Produce a smoother, more accurate surface.

7. How do you calculate the correct cutting speed and feed rate?

Sample Answer:

- Consider the material being cut.

- Refer to manufacturer’s recommendations.

- Use empirical data from previous experience.

- Adjust the cutting parameters based on the desired surface finish and production rate.

8. Explain the importance of quality control in Oakes machine operation?

Sample Answer:

- Ensures the production of high-quality parts.

- Reduces scrap and rework.

- Maintains customer satisfaction.

- Improves overall productivity and efficiency.

9. Describe your experience with programming and operating CNC Oakes machines?

Sample Answer:

- Familiarity with G-code programming.

- Experience operating different CNC Oakes machines.

- Ability to set up and optimize CNC programs.

- Knowledge of CNC control systems.

- Troubleshooting and maintenance experience.

10. How do you handle tight tolerances and complex geometries when operating Oakes machines?

Sample Answer:

- Careful setup and alignment of the machine.

- Use of precision tooling and measuring instruments.

- Advanced programming techniques to optimize toolpaths and minimize errors.

- Regular calibration and maintenance of the machine.

- Close attention to detail and adherence to quality control procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oakes Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oakes Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oakes Machine Operators are responsible for operating and maintaining Oakes machines, which are specialized machines used in the production of metal components. These machines are complex and require a high level of skill and expertise to operate safely and efficiently. The key responsibilities of an Oakes Machine Operator include:

1. Operating Oakes machines

Oakes Machine Operators are responsible for operating Oakes machines in accordance with established procedures. This includes setting up the machine, loading and unloading materials, and monitoring the machine during operation.

2. Maintaining Oakes machines

Oakes Machine Operators are also responsible for maintaining Oakes machines. This includes cleaning and lubricating the machine, as well as performing minor repairs and adjustments.

3. Inspecting products

Oakes Machine Operators are responsible for inspecting products produced by Oakes machines. This includes checking for defects and ensuring that the products meet quality standards.

4. Following safety procedures

Oakes Machine Operators must follow all safety procedures when operating and maintaining Oakes machines. This includes wearing appropriate safety gear, and following lockout/tagout procedures.

Interview Tips

Preparing for an interview for an Oakes Machine Operator position can be a daunting task. However, by following these tips, you can increase your chances of success:

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and values, and what they are looking for in a candidate.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked. By practicing answering these questions, you can become more comfortable and confident during the interview.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes and shoes.

4. Be on time

Punctuality is important, so make sure to arrive for your interview on time. This shows the interviewer that you are respectful of their time.

5. Be prepared to talk about your experience

During the interview, you will be asked to talk about your experience and qualifications. Be prepared to discuss your experience operating and maintaining Oakes machines.

6. Be prepared to answer questions about safety

Safety is a top priority for Oakes Machine Operators. Be prepared to answer questions about your safety knowledge and experience.

7. Be enthusiastic and positive

Employers are looking for candidates who are enthusiastic and positive. Be sure to show the interviewer that you are excited about the opportunity to work for their company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oakes Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!