Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted OD Grinder Operator (Outer Diameter Grinder Operator) position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

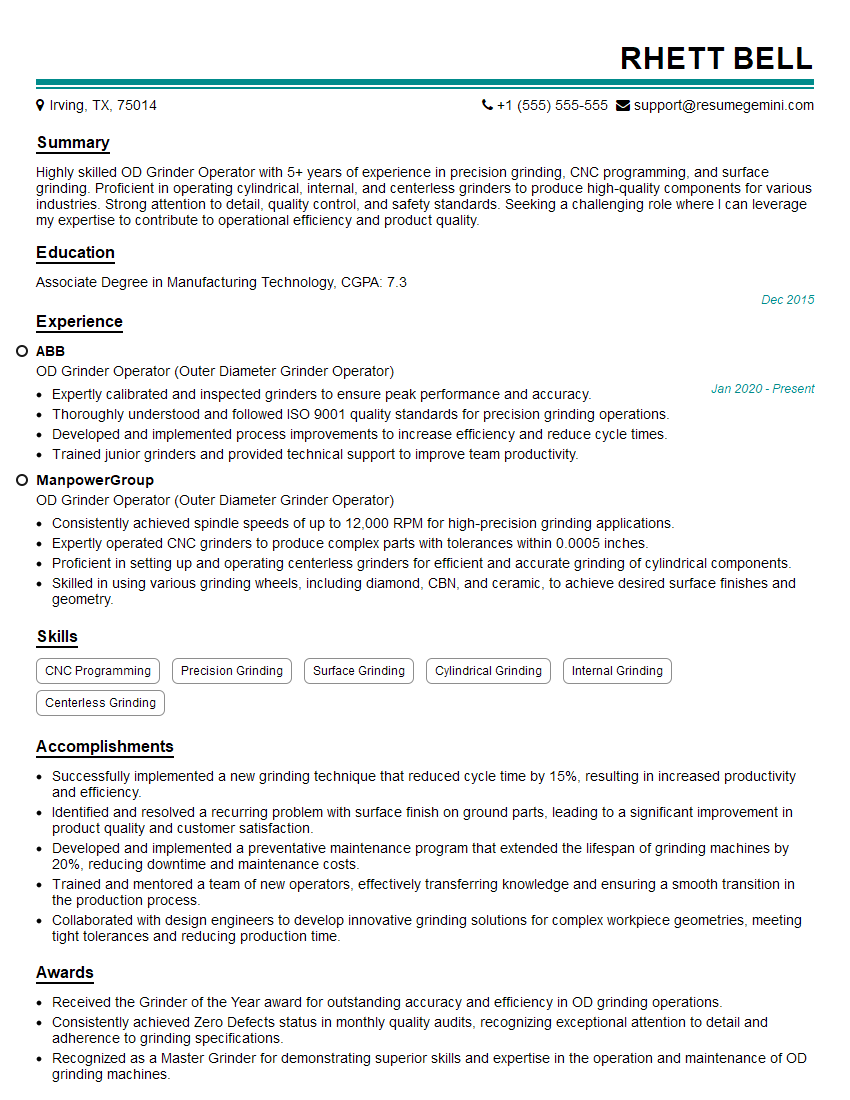

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For OD Grinder Operator (Outer Diameter Grinder Operator)

1. Explain the process of OD grinding in detail?

Answer:

- OD grinding, or outer diameter grinding, is a grinding process that involves the removal of material from the outer diameter of a cylindrical workpiece.

- The process is typically performed on a cylindrical grinder, which consists of a grinding wheel that rotates at high speeds and a table that holds the workpiece.

- The workpiece is fed into the grinding wheel, and the grinding wheel removes material from the outer diameter of the workpiece.

- The process is typically used to achieve precise dimensions, improve surface finish, or remove burrs from the workpiece.

2. What are the different types of OD grinding wheels?

Answer:

Types of OD Grinding Wheels:

- Conventional grinding wheels: These wheels are made of abrasive grains that are bonded together with a resin or ceramic bond.

- CBN grinding wheels: These wheels are made of cubic boron nitride (CBN) grains that are bonded together with a metal bond.

- Diamond grinding wheels: These wheels are made of diamond grains that are bonded together with a metal bond.

3. What are the factors that affect the surface finish of OD grinding?

Answer:

- The grit size of the grinding wheel

- The speed of the grinding wheel

- The feed rate of the workpiece

- The depth of cut

- The type of coolant used

4. What are the safety precautions that must be taken when operating an OD grinder?

Answer:

- Wear appropriate safety gear, including eye protection, ear protection, and gloves.

- Ensure that the grinding wheel is properly mounted and balanced.

- Use a wheel guard to protect yourself from flying debris.

- Keep the work area clean and free of debris.

- Never operate an OD grinder under the influence of drugs or alcohol.

5. What is the difference between plunge grinding and traverse grinding?

Answer:

- Plunge grinding: In this method, the grinding wheel is fed into the workpiece in a straight line.

- Traverse grinding: In this method, the grinding wheel is moved across the workpiece in a back-and-forth motion.

6. What are the different types of coolants used in OD grinding?

Answer:

- Water-based coolants: These coolants are made of water and a soluble oil.

- Oil-based coolants: These coolants are made of oil and a variety of additives.

- Synthetic coolants: These coolants are made of synthetic fluids and a variety of additives.

7. What is the purpose of using a dressing tool in OD grinding?

Answer:

- A dressing tool is used to shape the grinding wheel and to remove any glazed or loaded material from the wheel.

- Dressing the grinding wheel helps to maintain the wheel’s cutting efficiency and to improve the surface finish of the workpiece.

8. What are the common problems that can occur during OD grinding?

Answer:

- Chatter: This is a vibration that can occur during grinding, which can cause the workpiece to have a poor surface finish.

- Burn: This is a condition that occurs when the grinding wheel becomes too hot and damages the workpiece.

- Loading: This is a condition that occurs when the grinding wheel becomes clogged with workpiece material.

9. What are the different types of OD grinders?

Answer:

- Cylindrical grinders: These grinders are used to grind the outer diameter of cylindrical workpieces.

- Centerless grinders: These grinders are used to grind the outer diameter of workpieces without the use of centers.

- Surface grinders: These grinders are used to grind the flat surfaces of workpieces.

10. What is the importance of maintaining proper lubrication in an OD grinder?

Answer:

- Proper lubrication is essential for the smooth operation of an OD grinder.

- Lubrication helps to reduce friction and wear on the moving parts of the grinder, which can extend the life of the machine.

- Lubrication also helps to prevent the formation of rust and corrosion.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for OD Grinder Operator (Outer Diameter Grinder Operator).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the OD Grinder Operator (Outer Diameter Grinder Operator)‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Outer Diameter Grinder Operator (OD Grinder Operator) plays a critical role in the manufacturing process by operating and maintaining outer diameter grinding machines. Their key responsibilities include:

1. Machine Operation

- Setting up and operating outer diameter grinding machines according to specifications.

- Monitoring and adjusting machine parameters, such as speed, feed, and temperature.

- Ensuring optimal grinding conditions to achieve required part dimensions and surface finish.

2. Material Handling

- Loading and unloading workpieces into and out of the grinding machine.

- Inspecting workpieces before and after grinding to ensure they meet quality standards.

- Maintaining a clean and organized work area.

3. Tool Management

- Selecting and installing the appropriate grinding wheels and other tooling.

- Dressing and sharpening grinding wheels to maintain optimal cutting performance.

- Performing preventive maintenance on grinding machines and tooling.

4. Quality Control

- Measuring and inspecting ground workpieces using precision measuring instruments.

- Identifying and correcting any deviations from specifications.

- Documenting grinding parameters and inspection results.

Interview Tips

1. Research the Company and Industry

- Learn about the company’s business, products, and culture.

- Research the industry to understand current trends and best practices.

- This knowledge will help you tailor your answers and demonstrate your interest in the position.

2. Practice Your Answers

- Prepare responses to common interview questions, such as “Tell me about yourself” and “Why are you interested in this job?”

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your skills.

- Practice your answers out loud to improve your delivery and confidence.

3. Emphasize Your Skills and Experience

- Highlight your proficiency in operating outer diameter grinding machines.

- Quantify your results when possible, such as “Increased production output by 15% through optimized grinding parameters.”

- Demonstrate your understanding of grinding techniques, tool management, and quality control.

4. Ask Thoughtful Questions

- Show your interest and engagement by asking questions about the company, the position, and the industry.

- This demonstrates your proactive nature and desire to learn more.

- Consider asking about the company’s growth plans, safety procedures, or the opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the OD Grinder Operator (Outer Diameter Grinder Operator) interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.