Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Offset Printing Pressmen position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

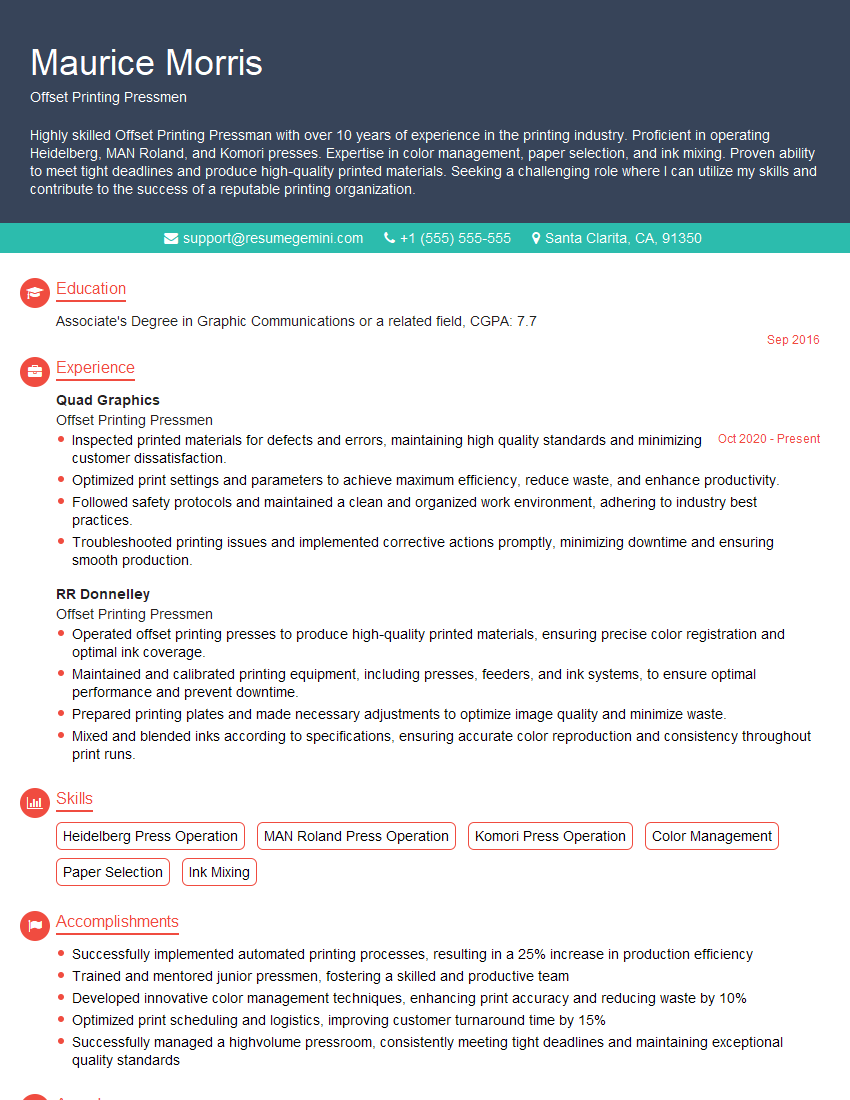

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Offset Printing Pressmen

1. what is the purpose of impression cylinder?

- Transfers the inked image from the plate cylinder to the paper.

- Controls the amount of pressure applied to the paper, which affects the quality of the printed image.

- Ensures that the paper is fed through the press smoothly and without wrinkles.

2. How do you adjust the ink-water balance on an offset printing press?

Adjusting Ink

- Check the density of the ink using a densitometer.

- Adjust the ink flow by turning the ink key or using the ink fountain controls.

- Monitor the printed output and make further adjustments as needed.

Adjusting Water

- Check the pH level of the fountain solution using a pH meter.

- Adjust the water flow by turning the water valve or using the fountain controls.

- Monitor the printed output and make further adjustments as needed.

3. what are the different types of printing plates used in offset printing?

- Presensitized Plates: Coated with a light-sensitive emulsion, exposed to light, and developed to create the image.

- Computer-to-Plate (CTP): Images are directly transferred from a computer to the plate using a laser or thermal process.

- Thermal Plates: Heat-sensitive plates that are imaged using a thermal laser or inkjet printer.

4. what are the key factors that affect the quality of an offset printed image?

- Plate quality and preparation

- Ink-water balance

- Press settings (pressure, speed, etc.)

- Paper quality and characteristics

- Environmental conditions (temperature, humidity, etc.)

5. how do you troubleshoot common printing problems such as ghosting, slurring, and banding?

Ghosting

- Check the ink-water balance.

- Inspect the printing plates for defects.

- Clean the blankets and impression cylinder.

Slurring

- Adjust the impression pressure.

- Check the paper feed system.

- Clean the printing plates.

Banding

- Inspect the rollers and replace any that are worn or damaged.

- Check the ink flow and adjust as needed.

- Clean the ink fountain and ink duct.

6. what are the safety precautions that must be followed when operating an offset printing press?

- Wear appropriate safety gear (gloves, safety glasses, etc.).

- Keep hands and loose clothing away from moving parts.

- Lock out and tag out equipment before performing maintenance or repairs.

- Follow proper chemical handling procedures when working with inks and solvents.

- Maintain a clean and organized work area.

7. what are the different types of paper used in offset printing?

- Coated Paper: Smooth, glossy surface that produces high-quality images.

- Uncoated Paper: Rough, absorbent surface that is suitable for everyday printing.

- Specialty Papers: Include textured, metallic, and translucent papers for unique effects.

8. what are the advantages and disadvantages of using different printing inks?

Advantages and Disadvantages of Different Inks

Petroleum-Based Inks:- Advantages: Durable, cost-effective, wide range of colors.

- Disadvantages: Can be slow to dry, prone to smudging.

- Advantages: Environmentally friendly, faster drying, less smudging.

- Disadvantages: More expensive, narrower color range.

- Advantages: Fast drying, vibrant colors, resistant to fading.

- Disadvantages: Specialized equipment required, can be more expensive.

9. what is the role of the prepress department in offset printing?

- Creates and prepares digital files for printing.

- Proofs and approves the final artwork before sending it to the press.

- Calibrates and maintains equipment used in prepress operations.

- Collaborates with the pressroom to ensure accurate color reproduction.

10. what are the key differences between offset printing and digital printing?

Offset Printing

- Uses printing plates to transfer ink to paper.

- Produces high-quality images with precise color reproduction.

- Suitable for long print runs and high-volume jobs.

Digital Printing

- Prints directly from digital files to paper.

- Faster and more cost-effective for short print runs.

- Offers variable data printing and personalization capabilities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Offset Printing Pressmen.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Offset Printing Pressmen‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Offset Printing Pressmen operate, maintain, and repair offset printing presses to produce high-quality printed materials. They have a strong understanding of printing processes and equipment, including color matching, paper handling, and press mechanics. Their primary responsibilities include:

1. Press Operation

Setting up and operating offset printing presses, ensuring proper ink flow, paper feeding, and print quality.

2. Color Matching

Matching colors accurately according to specifications, using color measurement tools and techniques.

3. Paper Handling

Selecting and loading different types of paper, adjusting tension and moisture levels to achieve optimal printing results.

4. Press Maintenance

Performing routine maintenance on printing presses, including cleaning, lubrication, and minor repairs.

5. Troubleshooting

Identifying and resolving printing problems, such as ink smudging, misalignment, or color issues.

Interview Tips

Preparing for an interview for an Offset Printing Pressmen position requires a combination of technical knowledge, industry experience, and professional presentation. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, thoroughly research the printing company and the specific role you’re applying for. This will demonstrate your interest in the position and help you tailor your answers to the company’s needs.

2. Review Printing Processes and Equipment

Brush up on your knowledge of offset printing processes, press mechanics, and color matching techniques. Review any industry-specific jargon or technical terms that may come up during the interview.

3. Showcase Your Experience

Highlight your relevant experience in operating and maintaining printing presses. Quantify your accomplishments whenever possible, using specific examples to demonstrate your skills and expertise.

4. Prepare for Technical Questions

Be prepared for technical questions related to press operation, troubleshooting, and color matching. Practice answering these questions clearly and concisely, providing practical examples from your experience.

5. Dress Professionally and Arrive Punctually

Make a good impression by dressing appropriately for the interview and arriving on time. Professionalism and punctuality reflect your respect for the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Offset Printing Pressmen interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!