Are you gearing up for an interview for a Oil Burner Installer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Oil Burner Installer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

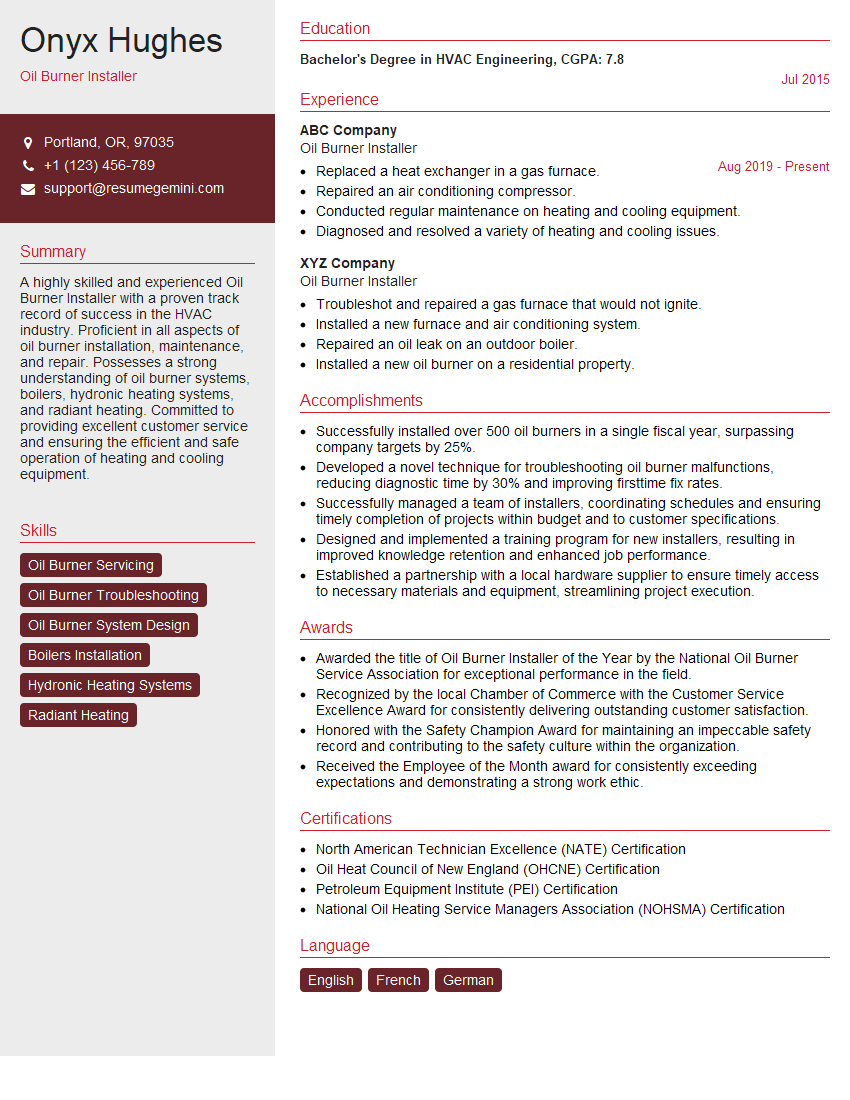

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Burner Installer

1. What are the key safety precautions you take when working on an oil burner system?

- Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Inspect the system for any potential hazards before starting work.

- Follow proper lockout/tagout procedures to prevent accidental energization.

- Handle combustible materials carefully and avoid any open flames or sparks.

- Be aware of the location of emergency shutoffs and know how to use them in case of an emergency.

2. Describe the process of diagnosing a faulty oil burner.

Troubleshooting Burner Issues

- Check the power supply to the burner.

- Inspect the fuel lines and connections for any leaks or blockages.

- Check the ignition system and flame sensor for proper operation.

- Measure the oil pressure and verify that it meets the specifications for the burner.

- Evaluate the fan motor and ensure that it is providing adequate airflow.

Troubleshooting Combustion Issues

- Analyze the flue gases to identify any combustion inefficiencies.

- Inspect the combustion chamber and burner nozzle for any soot or carbon buildup.

- Adjust the air-to-fuel ratio based on the combustion analysis results.

- Ensure that the burner is properly sized for the application.

3. Explain the importance of proper nozzle selection for an oil burner system.

- Selecting the correct nozzle size ensures efficient combustion and prevents issues such as sooting, flame instability, and incomplete burning.

- Proper nozzle selection minimizes fuel consumption and optimizes heating performance.

- The nozzle spray pattern and flow rate must be compatible with the burner design and fuel type.

- Using an incorrect nozzle can lead to poor combustion, reduced efficiency, and increased wear on the burner components.

4. Describe the steps involved in performing an annual maintenance on an oil burner system.

- Clean and inspect the burner nozzle and combustion chamber.

- Check and adjust the ignition system and flame sensor.

- Inspect the fuel lines and connections for any leaks or blockages.

- Measure the oil pressure and verify that it meets the specifications for the burner.

- Evaluate the fan motor and ensure that it is providing adequate airflow.

- Analyze the flue gases and adjust the air-to-fuel ratio if necessary.

- Lubricate moving parts and check belts for wear or damage.

- Perform safety checks and ensure that all components are operating properly.

5. Explain the different types of oil burner nozzles and their applications.

- Used in residential and commercial burners

- Produce a hollow cone spray pattern

- Available in various sizes and capacities

- Used in large commercial and industrial burners

- Produce a solid cone spray pattern

- Provide higher turndown ratios and can handle heavier fuels

- Used in large industrial burners

- Mix fuel with air to create a fine mist

- Provide excellent combustion efficiency and low emissions

Pressure Atomizing Nozzles

Rotary Atomizing Nozzles

Air Atomizing Nozzles

6. What are the advantages and disadvantages of using an oil burner system compared to other heating systems?

Advantages

- High efficiency and fuel economy

- Reliable and long-lasting

- Can be used with different types of oil

- Easy to maintain and service

Disadvantages

- Higher upfront costs compared to some other systems

- Requires a storage tank for fuel

- Can produce soot and emissions if not properly maintained

7. Describe the process of installing a new oil burner in a residential property.

- Obtain necessary permits and inspections.

- Remove the old burner and components.

- Install the new burner and connect it to the fuel lines and electrical system.

- Adjust the air-to-fuel ratio and perform combustion analysis.

- Test the system for proper operation and safety.

- Schedule regular maintenance and provide instructions to the homeowner.

8. Explain the importance of maintaining proper oil pressure in an oil burner system.

- Ensures efficient atomization and combustion

- Prevents damage to the burner nozzle and other components

- Optimizes fuel consumption and heating performance

- Improves the overall safety and reliability of the system

9. How do you troubleshoot a burner that is not igniting?

- Check for power supply and proper electrical connections.

- Inspect the ignition system and flame sensor.

- Ensure that there is a sufficient fuel supply and that the fuel lines are not blocked.

- Verify that the air-to-fuel ratio is set correctly.

- Clean the burner nozzle and combustion chamber.

- Check for any safety interlocks or lockout conditions that may be preventing ignition.

10. What are the environmental regulations and safety codes that apply to oil burner installations and maintenance?

- National Fire Protection Association (NFPA) 31: Installation of Oil-Burning Equipment

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) 15: Safety Code for Mechanical Refrigeration

- Local building codes and fire safety regulations

- Environmental Protection Agency (EPA) regulations on emissions and fuel efficiency

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Burner Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Burner Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oil Burner Installers are responsible for the installation, maintenance, and repair of oil burners. These skilled professionals ensure that oil-burning heating systems operate safely and efficiently, providing warmth to residential, commercial, and industrial buildings.

1. Installation

Install oil burners into heating systems, ensuring proper alignment and connection to fuel lines, electrical systems, and exhaust vents.

- Read and interpret blueprints and specifications to determine installation requirements.

- Assemble and install oil burner components, including pumps, nozzles, and igniters.

- Test and adjust burners to optimize combustion and efficiency.

2. Maintenance

Perform regular maintenance on oil burners to prevent breakdowns and ensure optimal performance.

- Clean and inspect burners, nozzles, and combustion chambers.

- Replace worn or damaged parts, such as filters and gaskets.

- Calibrate and adjust burners to maintain proper air-fuel ratios.

3. Repair

Diagnose and repair malfunctioning oil burners, restoring them to proper working condition.

- Troubleshoot electrical, mechanical, and combustion issues.

- Replace or repair damaged components, such as pumps, motors, and igniters.

- Test and verify repairs to ensure safety and functionality.

4. Safety

Adhere to safety regulations and industry standards to prevent accidents and ensure the safe operation of oil burners.

- Follow manufacturer’s instructions and observe proper handling and storage procedures for oil and other flammable materials.

- Inspect and maintain safety devices, such as flame sensors and over-temperature switches.

- Report any safety concerns or potential hazards to supervisors and customers.

Interview Tips

Preparing for an interview for an Oil Burner Installer position requires a combination of research, practice, and confidence. Here are some tips to help you ace the interview:

1. Research the Company and Role

Familiarize yourself with the company’s website, industry reputation, and the specific requirements of the job. This knowledge will help you tailor your answers and demonstrate your interest in the position.

- Example: By researching the company’s website, you may discover they prioritize sustainability. During the interview, you can emphasize your experience in installing energy-efficient oil burners that align with their values.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Practice delivering your answers clearly and confidently.

- Example: Prepare for questions such as “Describe your experience troubleshooting oil burner malfunctions” or “How do you ensure the safety of your work while handling flammable materials?”

3. Highlight Relevant Skills and Experience

Connect your skills and experience to the key responsibilities of the job. Provide specific examples that demonstrate your abilities.

4. Emphasize Safety and Regulations

Safety is paramount in this role. Highlight your understanding of industry regulations and your commitment to safe work practices.

- Example: You could mention your experience in adhering to National Fire Protection Association (NFPA) standards or your involvement in safety training programs.

5. Show Enthusiasm and Motivation

Express your passion for the industry and your desire to contribute to the company’s success. Your enthusiasm will leave a positive impression on the interviewer.

- Example: You could share your interest in renewable energy technologies and how you see oil burners as a transitional solution in the shift towards sustainable heating systems.

Next Step:

Now that you’re armed with the knowledge of Oil Burner Installer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Oil Burner Installer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini