Are you gearing up for an interview for a Oil Burner Servicer and Installer Helper position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Oil Burner Servicer and Installer Helper and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

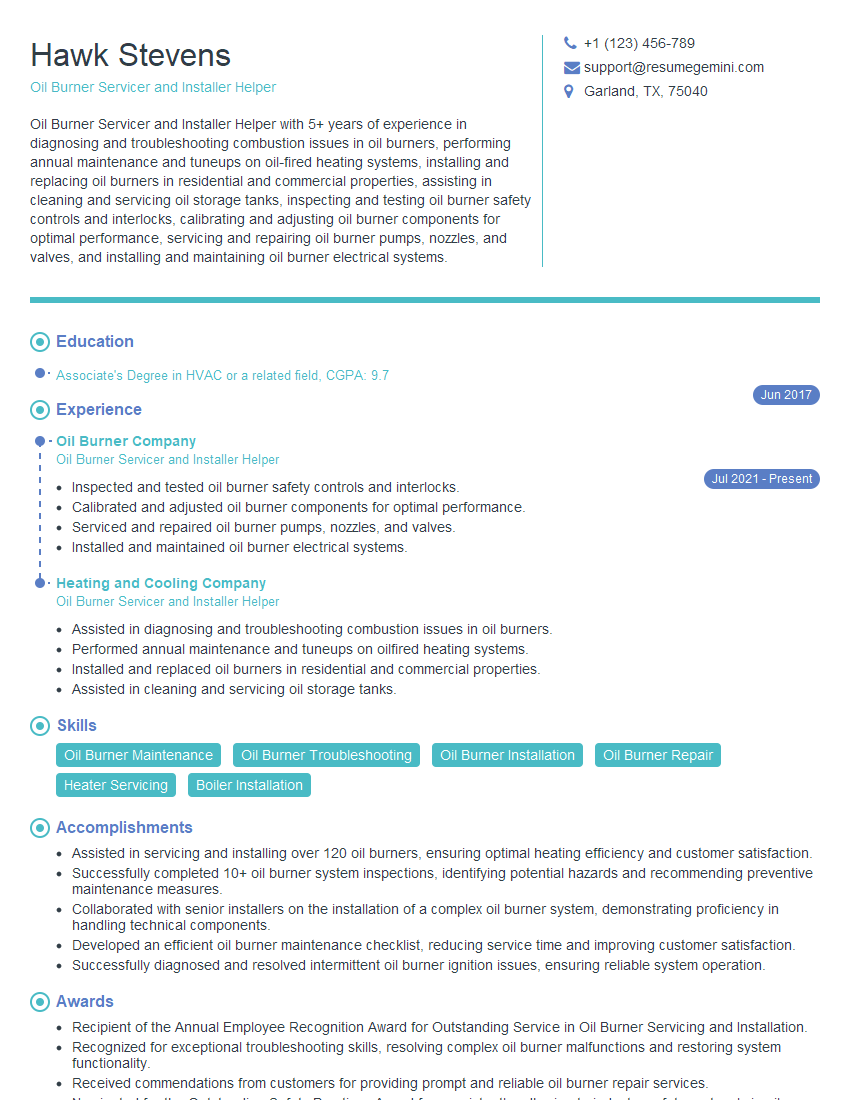

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Burner Servicer and Installer Helper

1. What are the common types of oil burners, and how do they differ in operation?

There are two main types of oil burners: pressure burners and rotary cup burners.

- Pressure burners use a pump to create a high-pressure stream of oil that is sprayed into the combustion chamber. This type of burner is commonly used in large commercial and industrial applications.

- Rotary cup burners use a spinning cup to atomize the oil and mix it with air before it is burned. This type of burner is often used in residential applications.

2. What are the key components of an oil burner, and what is the function of each component?

Fuel pump

- Delivers oil from the storage tank to the burner.

- Maintains a constant fuel pressure.

Oil filter

- Removes impurities from the oil.

- Protects the burner from damage.

Nozzle

- Atomizes the oil into a fine spray.

- Produces a proper air-fuel mixture.

Combustion chamber

- Where the oil and air are mixed and burned.

- Produces heat that is transferred to the heating system.

Flue pipe

- Carries combustion gases out of the building.

- Prevents carbon monoxide poisoning.

3. What are the most common problems that occur with oil burners, and how can they be diagnosed and fixed?

Some of the most common problems that occur with oil burners include:

- Nozzle clogging: This can be caused by impurities in the oil or by a worn nozzle. To fix this problem, the nozzle should be cleaned or replaced.

- Dirty flame sensor: This can cause the burner to shut off prematurely. To fix this problem, the flame sensor should be cleaned.

- Faulty ignition system: This can prevent the burner from starting. To fix this problem, the ignition system should be inspected and repaired or replaced.

- Leaking fuel lines: This can be a safety hazard. To fix this problem, the fuel lines should be inspected and repaired or replaced.

4. What safety precautions should be taken when working on oil burners?

When working on oil burners, it is important to take the following safety precautions:

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and a respirator.

- Work in a well-ventilated area.

- Keep a fire extinguisher nearby.

- Do not smoke or use open flames around oil burners.

- Follow all manufacturer’s instructions carefully.

5. What are the different types of oil burner nozzles, and how do they affect the performance of the burner?

There are two main types of oil burner nozzles: hollow cone nozzles and solid cone nozzles.

- Hollow cone nozzles produce a hollow cone-shaped spray pattern. This type of nozzle is often used in residential applications because it provides a good mixture of air and fuel.

- Solid cone nozzles produce a solid cone-shaped spray pattern. This type of nozzle is often used in commercial and industrial applications because it provides a more intense flame.

6. How do you troubleshoot an oil burner that is not starting?

If an oil burner is not starting, there are a few things that you can troubleshoot:

- Check the power supply to the burner.

- Check the fuel supply to the burner.

- Check the ignition system.

- Check the flame sensor.

- Check the nozzle for clogging.

7. How do you adjust the air-fuel ratio on an oil burner?

The air-fuel ratio on an oil burner can be adjusted by changing the size of the nozzle or by adjusting the air damper.

- To increase the air-fuel ratio, use a smaller nozzle or open the air damper.

- To decrease the air-fuel ratio, use a larger nozzle or close the air damper.

8. What are the different types of oil burner controls, and how do they work?

There are two main types of oil burner controls: manual controls and automatic controls.

- Manual controls require the operator to manually start and stop the burner.

- Automatic controls use a thermostat to automatically turn the burner on and off as needed.

9. What are the benefits of using an oil burner instead of other heating systems?

Oil burners offer a number of benefits over other heating systems, including:

- High efficiency: Oil burners are very efficient at converting fuel into heat.

- Reliability: Oil burners are very reliable and can provide years of trouble-free operation.

- Affordability: Oil is a relatively affordable fuel source.

- Convenience: Oil burners are convenient to use and require minimal maintenance.

10. What are the challenges of working as an oil burner servicer and installer helper?

There are a number of challenges associated with working as an oil burner servicer and installer helper, including:

- Working in confined spaces

- Working with hazardous materials

- Working in all weather conditions

- Being on call for emergencies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Burner Servicer and Installer Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Burner Servicer and Installer Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Oil Burner Servicer and Installer Helper plays a crucial role in maintaining and installing oil-fired heating systems, ensuring optimal performance and safety. Key responsibilities include:

1. Assisting in Oil Burner Servicing

Inspecting, cleaning, and adjusting oil burners to ensure efficient operation.

2. Assisting in Oil Burner Installation

Installing new oil burners, connecting them to fuel tanks and chimneys, and testing for proper functionality.

3. Troubleshooting and Repair

Identifying and resolving issues with oil burners, including ignition problems, flame stability, and fuel delivery.

4. Maintenance and Inspection

Performing routine inspections and preventive maintenance on oil burners and related systems, ensuring peak performance and preventing breakdowns.

Interview Preparation Tips

To ace your interview for the Oil Burner Servicer and Installer Helper role, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, services, and industry reputation. Understand the specific responsibilities and qualifications required for the role.

2. Highlight Relevant Experience and Skills

Emphasize your hands-on experience in servicing or installing oil burners. Quantify your accomplishments and provide specific examples of your troubleshooting abilities.

3. Demonstrate Safety Awareness

Stress your understanding of safety regulations and protocols related to handling oil burners and working with fuel systems. Mention any relevant certifications or safety training you have received.

4. Show Mechanical Aptitude

Explain your familiarity with the components and workings of oil burners. Discuss your ability to diagnose and repair mechanical issues, including tracing wiring diagrams.

5. Prepare for Technical Questions

Expect questions about common oil burner problems and troubleshooting techniques. Be ready to explain your approach to diagnosing and solving specific issues.

6. Be Enthusiastic and Professional

Convey your passion for working with oil burners and your commitment to providing exceptional customer service. Maintain a professional demeanor throughout the interview.

7. Practice Interview Questions

Prepare for potential interview questions by using online resources or seeking feedback from a mentor. This will enhance your confidence and articulation during the actual interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oil Burner Servicer and Installer Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.