Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oil Derrick Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

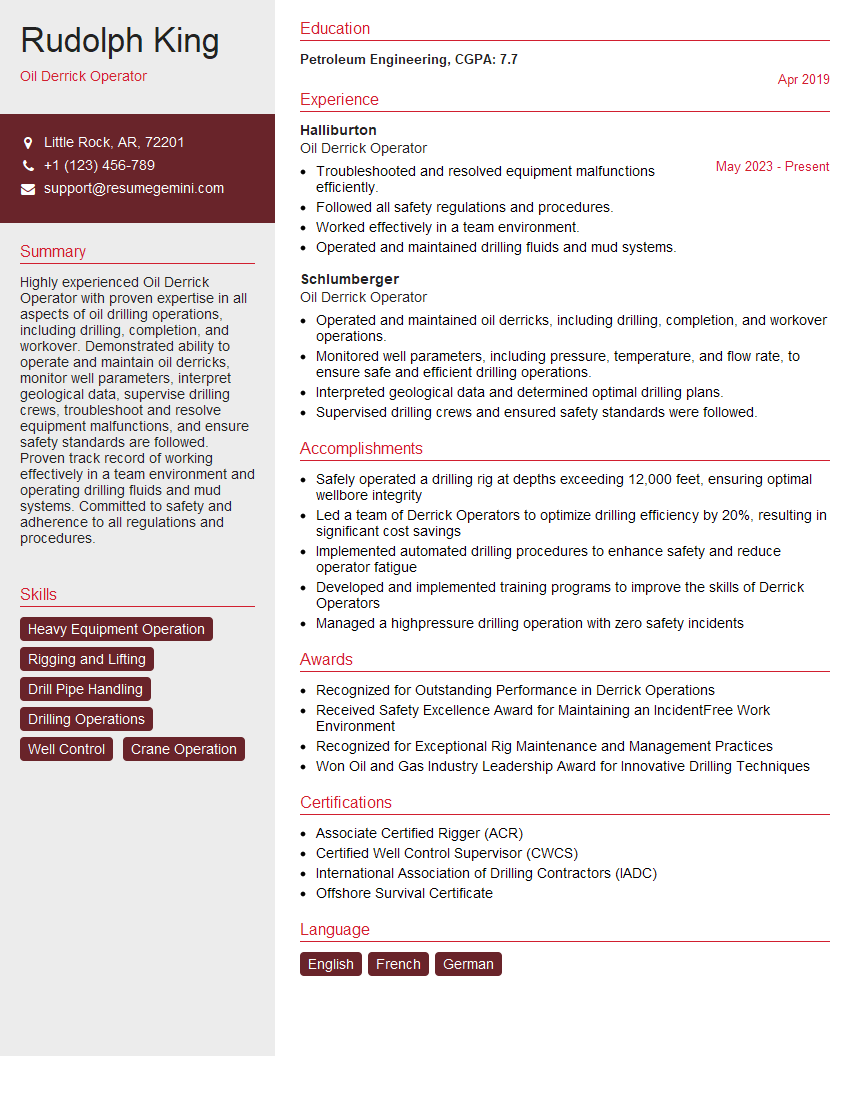

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Derrick Operator

1. Describe the key responsibilities of an Oil Derrick Operator.

As an Oil Derrick Operator, my primary responsibilities would include:

- Operating and maintaining oil drilling equipment, including derricks, draw works, and rotary tables.

- Monitoring drilling operations and ensuring adherence to safety protocols.

- Troubleshooting and resolving operational issues to ensure uninterrupted drilling.

- Working closely with other members of the drilling crew, including roughnecks and drillers.

- Maintaining a clean and organized work area, ensuring the proper storage and handling of materials and equipment.

2. Explain the importance of safety in oil derrick operations.

Risk Assessment and Mitigation

- Recognizing and assessing potential hazards in drilling operations.

- Implementing appropriate control measures to minimize risks.

Emergency Preparedness

- Understanding emergency procedures and evacuation plans.

- Being able to respond quickly and effectively to emergencies.

Compliance with Regulations

- Adhering to industry standards and government regulations.

- Ensuring that all equipment and procedures meet safety requirements.

3. Discuss the different types of drilling rigs used in oil and gas operations.

- Land Rigs: Used for drilling onshore, characterized by large structures and high power.

- Offshore Rigs: Used for drilling at sea, including jack-up rigs, semi-submersible rigs, and drill ships.

- Mobile Rigs: Compact and easily transportable, designed for quick deployment in various locations.

- Slim Hole Rigs: Used for drilling narrow boreholes in exploration or tight formations.

- Coiled Tubing Rigs: Utilizing continuous tubing for drilling, interventions, and wellbore maintenance.

4. Describe the role of mud in oil drilling operations.

- Lubrication and Cooling: Reduces friction between drill bit and borehole walls, preventing overheating.

- Wellbore Stability: Maintains hydrostatic pressure to prevent collapse and fluid influx.

- Cutting Removal: Carries cuttings away from the drill bit and up the annulus.

- Formation Evaluation: Provides information about subsurface formations through analysis of cuttings and mud logs.

5. Explain the principles of directional drilling.

- Deviation Control: Using steerable drilling assemblies to deviate the wellbore from vertical.

- Kick-off Point: The depth at which the wellbore begins to deviate from vertical.

- Build Rate: The rate at which the angle of deviation increases with depth.

- Hold Section: Maintaining a constant angle of deviation for a specific interval.

6. Describe the process of running casing in an oil well.

- Casing Design: Selecting the appropriate casing size, weight, and grade for the well conditions.

- Casing Running: Lowering the casing into the wellbore using a casing crew and rig equipment.

- Casing Cementing: Pumping cement slurry into the annulus between the casing and the borehole to provide structural support.

- Casing Perforating: Creating perforations in the casing to allow fluid flow from the formation into the wellbore.

7. Explain the different methods of artificial lift used in oil and gas production.

- Gas Lift: Injecting gas into the wellbore to reduce fluid density and enhance flow.

- Electrical Submersible Pump (ESP): Submersible pump placed downhole to lift fluids.

- Hydraulic Submersible Pump (HSP): Powered by hydraulic fluid from the surface.

- Sucker Rod Pump: Surface-operated pump connected to the downhole plunger by sucker rods.

- Progressive Cavity Pump (PCP): Positive displacement pump that operates with a helical stator and rotor.

8. Discuss the importance of well logging in oil and gas exploration.

- Formation Evaluation: Providing information about rock properties, fluid content, and reservoir characteristics.

- Wellbore Integrity Assessment: Identifying potential problems with the wellbore or casing.

- Hydrocarbon Detection: Identifying zones containing oil and gas.

- Reservoir Monitoring: Tracking changes in reservoir conditions over time.

9. Explain the role of blowout preventers (BOPs) in oil drilling operations.

- Primary Control: Preventing uncontrolled flow of fluids from the wellbore during drilling and completion operations.

- Secondary Control: Providing backup in case of failure of the primary control system.

- Types of BOPs: Annular BOPs, ram BOPs, and shear rams.

- Routine Testing: Regular testing to ensure proper functionality and reliability.

10. Describe the environmental regulations and best practices followed in oil derrick operations.

- Spill Prevention and Control: Implementing measures to prevent and mitigate oil spills.

- Waste Management: Managing drilling fluids, cuttings, and other waste materials responsibly.

- Air Quality Control: Minimizing emissions and implementing measures to reduce air pollution.

- Noise Reduction: Using noise-reducing technologies and implementing operational measures to minimize noise levels.

- Habitat Protection: Minimizing disturbance to wildlife and ecosystems in drilling areas.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Derrick Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Derrick Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oil Derrick Operators perform a wide range of physically demanding tasks associated with the operation and maintenance of oil drilling equipment on offshore oil rigs and platforms. Their primary responsibilities include:

1. Equipment Operation

Operate and maintain oil drilling equipment such as derricks, drawworks, mud pumps, and rotary tables. Monitor gauges, screens, and other instruments to ensure proper operation.

- Control the raising and lowering of the drill pipe.

- Operate blowout preventers to control well pressure.

2. Rig Maintenance

Perform routine maintenance and repairs on drilling equipment, including lubrication, cleaning, and inspection. Troubleshoot and resolve mechanical issues.

- Inspect and maintain drilling tools and equipment.

- Replace worn or damaged parts.

3. Safety Management

Follow safety protocols and procedures to ensure a safe work environment. Monitor for potential hazards and take appropriate actions to mitigate risks.

- Conduct safety inspections and drills.

- Enforce safety regulations and protocols.

4. Teamwork and Communication

Work effectively as part of a team to complete tasks efficiently and safely. Communicate clearly and effectively with other crew members, supervisors, and engineers.

- Coordinate with other team members to ensure smooth operations.

- Provide feedback and report on equipment performance.

Interview Tips

Preparing thoroughly for an Oil Derrick Operator interview can significantly increase your chances of success. Here are a few key tips to consider:

1. Research the Company and Position

Familiarize yourself with the specific oil company, its operations, and the role you are applying for. This will demonstrate your interest and enthusiasm for the opportunity.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating and maintaining oil drilling equipment. Showcase your knowledge of safety protocols and your ability to work as part of a team.

3. Demonstrate Physical Fitness and Endurance

Oil Derrick Operators perform physically demanding tasks. Be prepared to discuss your physical fitness and how you can meet the rigors of the job.

4. Practice Behavioral Interview Questions

Interviewers often ask behavioral questions to assess your problem-solving abilities and teamwork skills. Prepare examples of situations where you successfully handled challenges or worked effectively with others.

Next Step:

Now that you’re armed with the knowledge of Oil Derrick Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Oil Derrick Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini