Feeling lost in a sea of interview questions? Landed that dream interview for Oil Recovery Unit Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Oil Recovery Unit Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

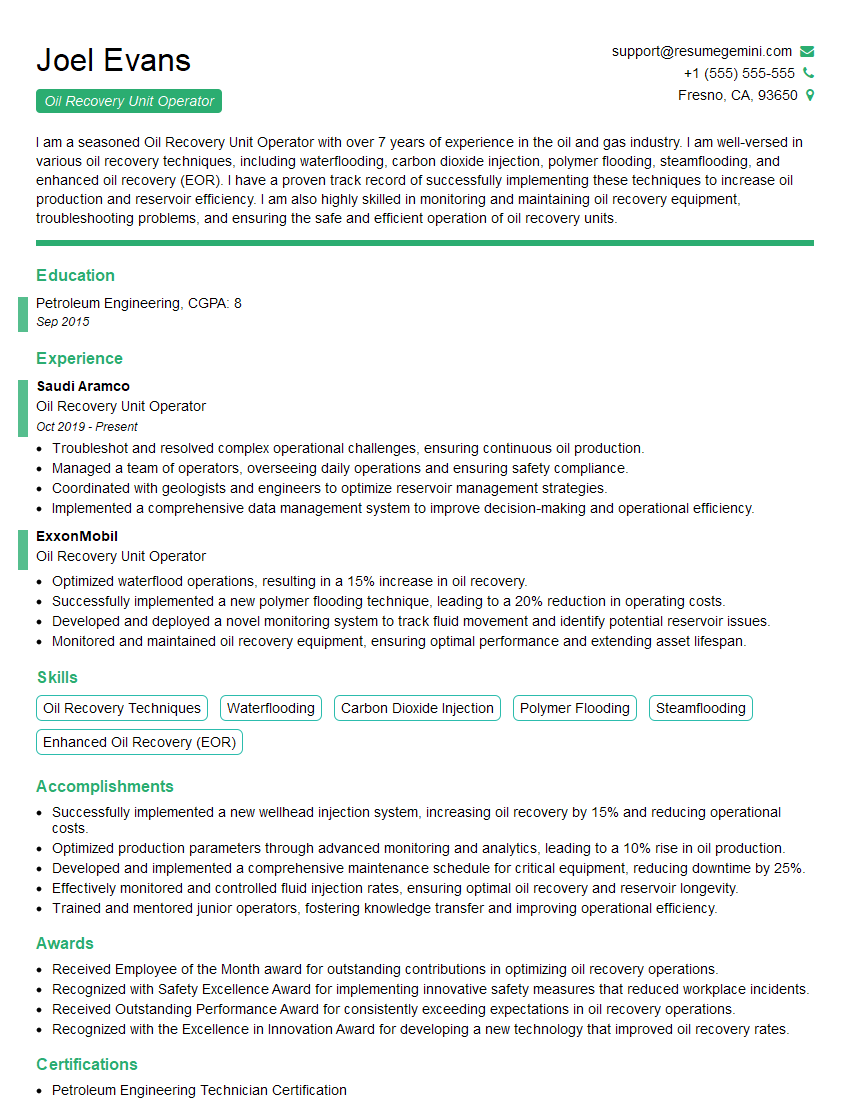

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Recovery Unit Operator

1. What are the different types of oil recovery methods?

- Primary recovery: This involves using natural energy sources, such as pressure from the reservoir to push oil to the surface.

- Secondary recovery: This involves injecting fluids, such as water or gas, into the reservoir to increase pressure and force oil to the surface.

- Tertiary recovery: This involves using more advanced techniques, such as chemical flooding or thermal methods, to recover oil that cannot be recovered using primary or secondary methods.

2. What are the key performance indicators (KPIs) for an oil recovery unit?

- Production rate: The amount of oil produced per day or month.

- Recovery factor: The percentage of oil that is recovered from the reservoir.

- Operating costs: The cost of operating the oil recovery unit.

- Environmental performance: The impact of the oil recovery unit on the environment.

3. What are the safety procedures that must be followed when operating an oil recovery unit?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a hard hat.

- Follow all operating procedures and safety protocols.

- Be aware of the location of all safety equipment and know how to use it.

- Report any unsafe conditions or incidents to your supervisor immediately.

4. What are the environmental regulations that apply to oil recovery operations?

- The Clean Air Act.

- The Clean Water Act.

- The Resource Conservation and Recovery Act.

- The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA).

5. What are the different types of pumps used in oil recovery operations?

- Positive displacement pumps: These pumps use a piston or diaphragm to move fluid through the pump.

- Centrifugal pumps: These pumps use a rotating impeller to move fluid through the pump.

- Axial flow pumps: These pumps use a propeller to move fluid through the pump.

6. What are the different types of separators used in oil recovery operations?

- Gravity separators: These separators use the difference in density between oil and water to separate the two fluids.

- Centrifugal separators: These separators use centrifugal force to separate oil and water.

- Electrostatic separators: These separators use an electrical charge to separate oil and water.

7. What are the different types of treatment processes used in oil recovery operations?

- Desalting: This process removes salt from oil.

- Dehydration: This process removes water from oil.

- Stabilization: This process stabilizes the oil to prevent it from forming emulsions.

8. What are the different types of storage tanks used in oil recovery operations?

- Atmospheric storage tanks: These tanks are open to the atmosphere.

- Pressure storage tanks: These tanks are closed to the atmosphere and are pressurized.

- Underground storage tanks: These tanks are buried underground.

9. What are the different types of transportation methods used in oil recovery operations?

- Pipelines: This is the most common method of transporting oil.

- Trucks: This is a more expensive method of transporting oil, but it is used when pipelines are not available.

- Rail cars: This is a less common method of transporting oil, but it is used when pipelines and trucks are not available.

- Ships: This is the most expensive method of transporting oil, but it is used when pipelines, trucks, and rail cars are not available.

10. What are the different types of maintenance tasks that are performed on oil recovery equipment?

- Preventive maintenance: This is maintenance that is performed on a regular basis to prevent equipment from breaking down.

- Corrective maintenance: This is maintenance that is performed to repair equipment that has broken down.

- Predictive maintenance: This is maintenance that is performed to predict when equipment is likely to break down and to prevent it from happening.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Recovery Unit Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Recovery Unit Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oil Recovery Unit Operators are responsible for operating and maintaining machinery such as oil pumps and separators to extract oil from oil and gas wells. Their main job duties include:

1. Equipment Operation

Operate and maintain machinery such as oil pumps, separators, and related equipment to extract oil from oil and gas wells.

- Monitor and adjust equipment settings to ensure optimal performance.

- Troubleshoot and resolve equipment malfunctions and breakdowns.

2. Production Monitoring

Monitor production data, including flow rates, pressure, and temperature, to ensure that oil and gas production meets targets.

- Identify and address any production issues promptly.

- Implement corrective actions to improve production efficiency.

3. Health and Safety

Ensure that all operations are conducted safely and in compliance with established health and safety regulations.

- Conduct regular safety checks and maintenance on equipment.

- Follow established safety protocols and procedures.

4. Maintenance and Repair

Perform routine maintenance and repairs on equipment to ensure its optimal operation.

- Replace worn or broken parts and components.

- Lubricate and adjust equipment as needed.

Interview Tips

To excel in an Oil Recovery Unit Operator interview, consider these effective preparatory strategies:

1. Research the Company and Position

Thoroughly research the oil and gas industry, the company’s operations, and the specific role you’re applying for. This knowledge will demonstrate your interest and enthusiasm for the position.

- Visit the company website and explore their annual reports, press releases, and sustainability initiatives.

- Review industry publications and articles to stay updated on the latest advancements and trends in oil recovery techniques.

2. Practice Common Interview Questions

Below is a set of common interview questions and sample answers to guide your preparation. Tailor your responses to highlight your relevant experience and align with the job description:

Example Outline:

Question: Tell me about your experience in operating oil recovery equipment. Answer: In my previous role at [Company Name], I was responsible for operating and maintaining oil pumps, separators, and other equipment used to extract oil from wells. I ensured optimal performance by monitoring flow rates, pressure, and temperature, and promptly addressed any production issues. Question: How do you ensure that operations are conducted safely? Answer: Safety is paramount in my work. I strictly adhere to established health and safety regulations. I conduct regular safety checks on equipment, follow safety protocols, and ensure that all personnel are aware of potential hazards and emergency procedures.3. Highlight Transferable Skills

Emphasize transferable skills that are relevant to the role, even if they were gained in different industries or positions. For instance, if you have experience in operating and maintaining industrial machinery, highlight your ability to troubleshoot and resolve technical issues.

- Communication and interpersonal skills: Demonstrate your ability to communicate effectively with colleagues, supervisors, and clients.

- Problem-solving and analytical skills: Showcase your ability to identify and solve problems, analyze data, and make informed decisions.

4. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive punctually for your interview. This demonstrates respect for the interviewer and the company.

Next Step:

Now that you’re armed with the knowledge of Oil Recovery Unit Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Oil Recovery Unit Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini