Are you gearing up for an interview for a Oil Refinery Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Oil Refinery Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

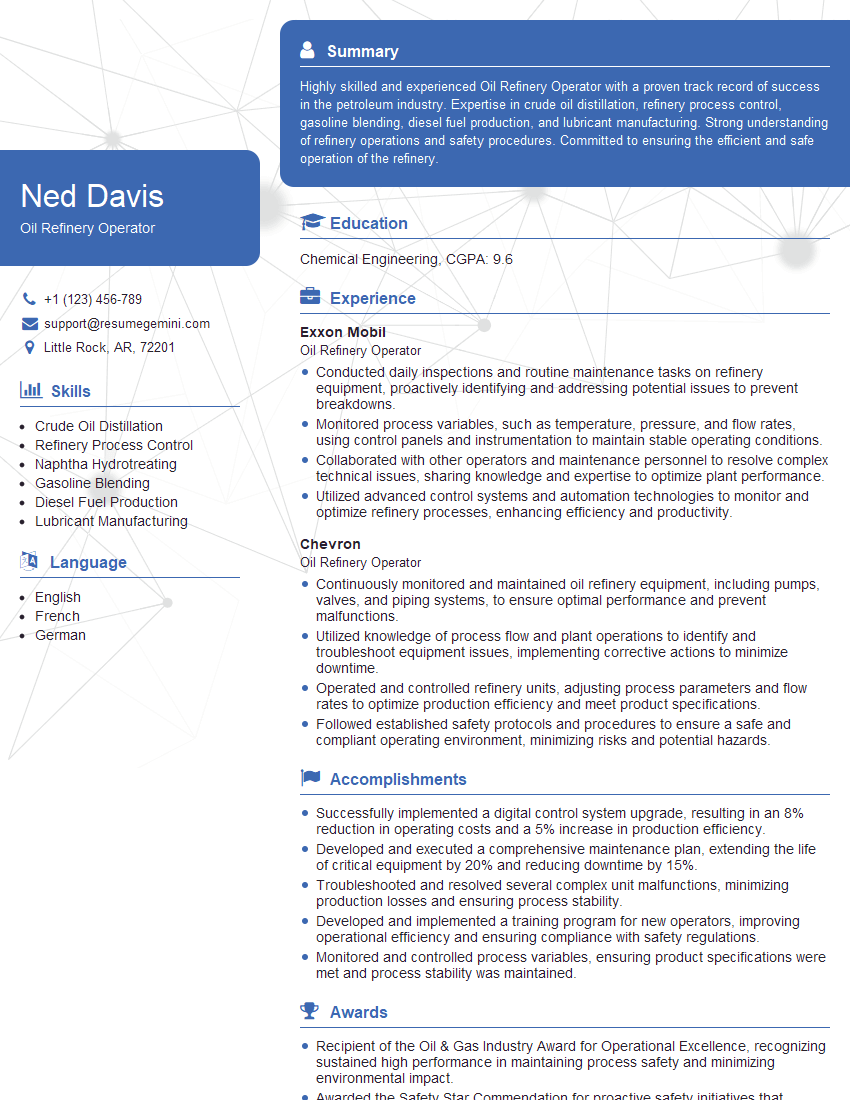

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Refinery Operator

1. Describe the process of distillation in an oil refinery?

Distillation is a process used in oil refineries to separate different components of crude oil based on their boiling points. Here’s an overview of the process:

- Preheating: Crude oil is preheated to reduce its viscosity and facilitate separation.

- Distillation Column: The preheated oil is fed into a distillation column, a vertical vessel with multiple trays or plates.

- Boiling Point Separation: As the oil rises through the column, different components vaporize at different temperatures. Lighter components, such as gases and light hydrocarbons, rise to the top, while heavier components, such as diesel and fuel oil, condense at lower levels.

- Fractionation: The trays in the column are designed to provide multiple contact points between the rising vapors and descending condensed liquids. This promotes further separation, ensuring that components with similar boiling points are grouped together.

- Distillate Collection: The separated components are collected at different levels of the column. Lighter fractions, such as gasoline and kerosene, are taken off from the top, while heavier fractions, such as diesel and fuel oil, are drawn off from the bottom.

2. How do you ensure the safe operation of equipment and systems in an oil refinery?

Safety Protocols:

- Adhering to established safety procedures and guidelines.

- Wearing appropriate personal protective equipment (PPE).

- Following lockout/tagout procedures during maintenance or repairs.

Equipment Monitoring:

- Regularly inspecting equipment for leaks, corrosion, and other potential hazards.

- Using sensors and alarms to monitor pressure, temperature, and fluid levels.

- Performing preventive maintenance to minimize equipment failures.

Emergency Preparedness:

- Being familiar with emergency response plans and procedures.

- Participating in regular drills and training exercises.

- Knowing the location and operation of safety equipment, such as fire extinguishers and spill containment kits.

3. How do you handle process upsets or abnormal conditions in a refinery?

- Remain Calm and Assess the Situation: Maintain composure and gather information about the upset, including its cause and potential impact.

- Follow Established Procedures: Refer to written procedures or consult with supervisors for guidance on appropriate actions.

- Isolate the Affected Area: Take steps to isolate the affected process or equipment to prevent the upset from spreading.

- Implement Corrective Actions: Determine the root cause of the upset and implement corrective measures to restore normal operation.

- Communicate with Others: Inform supervisors, maintenance personnel, and other relevant parties about the upset and the actions being taken.

- Document the Event: Record details of the upset, including its cause, the actions taken, and the lessons learned.

4. Describe the role of instrumentation and control systems in an oil refinery?

- Process Monitoring: Instrumentation provides real-time data on process parameters such as temperature, pressure, flow rate, and fluid levels.

- Control and Automation: Control systems use the information from instrumentation to automatically adjust valves, pumps, and other equipment to maintain desired process conditions.

- Safety Interlocks: Instrumentation and control systems can be integrated with safety interlocks to automatically shut down processes in the event of abnormal conditions.

- Data Analysis and Optimization: Control systems collect and analyze data to identify areas for improvement and optimize process efficiency.

5. How do you maintain and troubleshoot electrical systems in a refinery?

Maintenance:

- Regularly inspecting electrical equipment for damage or wear.

- Cleaning and lubricating components to prevent corrosion and ensure smooth operation.

- Performing insulation resistance tests and other preventive measures to identify potential issues.

Troubleshooting:

- Using electrical diagrams and schematics to identify the source of a fault.

- Testing circuits and components with specialized tools.

- Replacing faulty components and repairing damaged wiring.

6. What experience do you have with process control techniques?

- PID Control: Tuning and optimizing PID (Proportional-Integral-Derivative) controllers to regulate process variables.

- Advanced Control Strategies: Implementing advanced control techniques such as model predictive control (MPC) and fuzzy logic.

- Process Simulation: Using process simulation software to model and analyze process dynamics and control strategies.

7. How do you ensure the quality and consistency of products in an oil refinery?

- Sampling and Testing: Regular sampling and testing of products to verify their compliance with specifications.

- Quality Control Procedures: Implementation of quality control procedures to monitor and adjust processes to meet quality standards.

- Statistical Process Control (SPC): Using statistical techniques to analyze product quality data and identify areas for improvement.

8. What are the different types of pumps used in an oil refinery?

- Centrifugal Pumps: Used for transferring large volumes of fluids at low to medium pressures.

- Positive Displacement Pumps: Used for precise metering or transferring fluids against high pressures.

- Reciprocating Pumps: Used for high-pressure applications, such as boiler feed pumps.

- Submersible Pumps: Used for pumping fluids from underground tanks or wells.

9. How do you protect pipelines and storage tanks from corrosion?

- Corrosion Inhibitors: Adding chemical inhibitors to pipelines and tanks to reduce corrosion rates.

- Cathodic Protection: Using an electrical current to protect metal surfaces from corrosion.

- Protective Coatings: Applying protective coatings, such as paint or epoxy, to create a barrier between the metal and corrosive substances.

- Regular Inspection and Maintenance: Regularly inspecting pipelines and tanks for signs of corrosion and performing maintenance as needed.

10. What are the environmental regulations that apply to oil refineries?

- Clean Air Act: Regulates air emissions from refineries, including particulate matter, sulfur dioxide, and nitrogen oxides.

- Clean Water Act: Regulates water discharges from refineries, including wastewater treatment and spill prevention.

- Resource Conservation and Recovery Act (RCRA): Manages hazardous waste generated by refineries, including spent catalysts and solvents.

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA): Addresses the cleanup of contaminated sites, including oil spills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Refinery Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Refinery Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oil Refinery Operators are responsible for the safe and efficient operation of oil refineries. They monitor and control the flow of oil and gas through the refinery, ensuring that the products meet quality specifications. They also perform maintenance and repairs on refinery equipment.

1. Monitor and Control Refinery Operations

Operators monitor and control the flow of oil and gas through the refinery using a variety of instruments and controls. They make adjustments to the process to ensure that the products meet quality specifications.

- Monitor the flow of oil and gas through the refinery.

- Control the temperature, pressure, and flow rate of the oil and gas.

- Ensure that the products meet quality specifications.

2. Perform Maintenance and Repairs

Operators perform maintenance and repairs on refinery equipment to ensure that the refinery is operating safely and efficiently.

- Inspect and repair refinery equipment.

- Replace worn or damaged parts.

- Lubricate and maintain equipment.

3. Work with Other Employees

Operators work with other employees in the refinery to ensure that the refinery is operating safely and efficiently.

- Communicate with other employees.

- Coordinate activities with other employees.

- Assist other employees with tasks.

4. Follow Safety Procedures

Operators must follow safety procedures to ensure the safety of themselves and others. They must be aware of the hazards associated with working in a refinery and take steps to protect themselves and others from injury.

- Follow safety procedures.

- Wear personal protective equipment.

- Be aware of the hazards associated with working in a refinery.

Interview Tips

Preparing for an interview can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before the interview, take some time to research the company and the position. This will help you understand the company’s culture and the specific requirements of the job.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. Practice your answers to these questions so that you can deliver them confidently and concisely.

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or business casual attire.

4. Arrive on Time

Punctuality is important, so make sure you arrive on time for your interview. If you are running late, call the interviewer to let them know.

5. Be Polite and Respectful

Be polite and respectful to everyone you meet during your interview, from the receptionist to the interviewer. This will show that you are a professional and that you are interested in the job.

6. Ask Questions

At the end of the interview, ask the interviewer questions about the job and the company. This will show that you are interested in the job and that you are eager to learn more about the company.

7. Follow Up

After the interview, send a thank-you note to the interviewer. This will show that you appreciate the opportunity to interview and that you are still interested in the job.

Next Step:

Now that you’re armed with the knowledge of Oil Refinery Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Oil Refinery Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini