Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oil Rigger position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

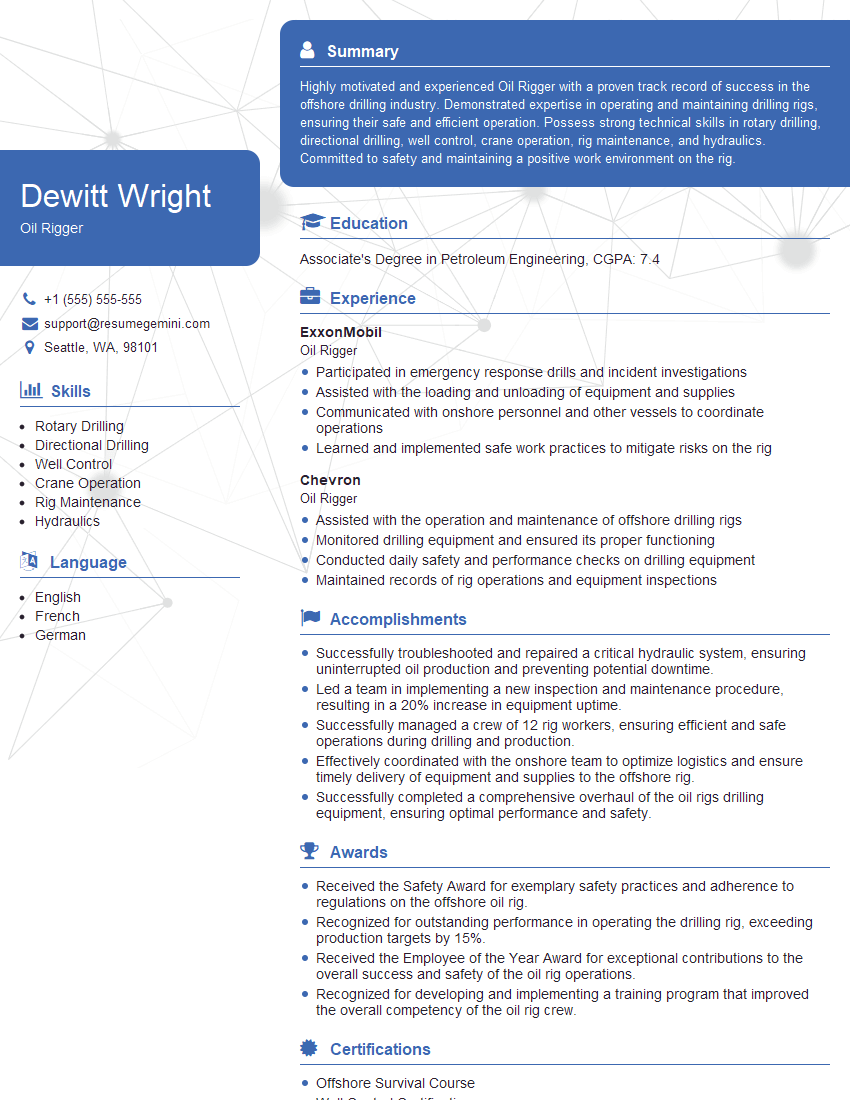

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Rigger

1. Describe the role and responsibilities of an Oil Rigger?

As an Oil Rigger, my primary responsibilities involve working on offshore oil rigs, performing various tasks related to drilling, maintenance, and operation of the equipment.

- Operate and maintain drilling rigs, pumps, and other equipment.

- Inspect and repair equipment to ensure optimal performance.

- Monitor drilling operations and maintain drilling records.

- Assist in the assembly and disassembly of drilling rigs.

- Follow safety protocols and regulations.

2. Explain the different types of drilling rigs used in the offshore industry?

Jackup Rigs

- Elevated on legs that can be raised or lowered.

- Used in shallow waters (less than 400 feet).

Semi-Submersible Rigs

- Partially submerged, with the drilling platform located above the waterline.

- Used in deeper waters (up to 6,000 feet).

Drillships

- Floating vessels that can drill in deep waters (over 6,000 feet).

- Equipped with advanced drilling systems.

3. What are the key safety measures and protocols followed on an oil rig?

- Wearing appropriate personal protective equipment (PPE).

- Following established work procedures and risk assessments.

- Maintaining clear communication and coordination with colleagues.

- Adhering to emergency response plans and evacuation procedures.

- Undergoing regular safety training and refresher courses.

4. Describe the process of drilling an offshore well?

- Planning and Preparation: Determine well location, design, and drilling plan.

- Rig Positioning: Position the drilling rig at the well site.

- Drilling: Use a drill bit to create a hole in the earth, circulating drilling fluid to remove cuttings.

- Casing and Cementing: Insert steel casing into the hole and secure it with cement to stabilize the wellbore.

- Completion: Install production tubing, downhole equipment, and safety systems to prepare the well for production.

5. What are the different types of drilling fluids used and their functions?

Water-Based Fluids

- Used in most drilling operations.

- Cool and lubricate the drill bit.

- Carry cuttings to the surface.

Oil-Based Fluids

- Provide lubrication and stability.

- Inhibit corrosion.

- Reduce formation damage.

Synthetic Fluids

- High-performance fluids with specific properties.

- Designed for challenging drilling conditions, such as high temperatures or corrosive environments.

6. Explain the principles of directional drilling and its applications?

- Deviation: Intentional deviation from a vertical path.

- Techniques: Motor-driven drilling, rotary steerable systems, and whipstocks.

- Applications: Reaching targets below obstacles, accessing multiple reservoirs, and enhancing production.

7. Describe the methods for maintaining and repairing oil rig equipment?

- Preventive Maintenance: Regular inspections, lubrication, and adjustments to prevent breakdowns.

- Corrective Maintenance: Repairing or replacing faulty equipment.

- Overhaul and Refurbishment: Major repairs or upgrades to extend the lifespan of equipment.

8. How do you ensure the accuracy and integrity of drilling data and records?

- Calibration of Equipment: Ensuring measuring devices are accurate.

- Data Verification: Cross-checking data from multiple sources.

- Documentation and Reporting: Maintaining detailed records of drilling parameters and observations.

- Quality Control: Implementing processes to ensure data accuracy and integrity.

9. What are the environmental hazards associated with offshore drilling operations?

- Oil Spills: Potential release of oil during drilling or transportation.

- Chemical Discharges: Use and disposal of drilling fluids and other chemicals.

- Noise Pollution: Noise generated by drilling equipment and support vessels.

- Waste Management: Handling and disposal of drilling cuttings and solid waste.

10. How do you prioritize safety and environmental protection on an oil rig?

- Risk Assessment: Identifying potential hazards and implementing controls.

- Emergency Preparedness: Developing and practicing emergency response plans.

- Training and Awareness: Providing training to personnel on safety procedures and environmental best practices.

- Continuous Improvement: Regularly reviewing and updating safety and environmental management systems.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Rigger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Rigger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oil Riggers play a crucial role in the operation and maintenance of oil rigs, ensuring the safe and efficient extraction of oil and gas from offshore wells. Their key responsibilities include:

1. Rig Setup and Dismantling

Assisting in the assembly, installation, and dismantling of drilling rigs and associated equipment, including derricks, drilling platforms, and mud systems.

2. Maintenance and Inspection

Performing routine maintenance and inspections of rig components, such as pumps, valves, and electrical systems, to ensure optimal functioning and prevent breakdowns.

3. Equipment Operation

Operating and controlling various rig equipment, including cranes, winches, and drilling machinery, to facilitate drilling and production operations.

4. Drilling Support

Supporting drilling crews by assisting with pipe handling, mud circulation, and monitoring drilling parameters, ensuring safety and efficiency during drilling operations.

5. Emergency Response

Responding promptly to emergencies and hazardous situations, such as fires, spills, or equipment failures, and implementing appropriate safety protocols.

6. Compliance and Safety

Adhering to safety regulations and industry standards, maintaining a clean and organized work environment, and ensuring the well-being of fellow crew members.

Interview Tips

To ace the interview for an Oil Rigger position, candidates should prepare thoroughly and demonstrate their knowledge, skills, and commitment to safety and teamwork.

1. Essential Skills

Highlight your proficiency in relevant skills, such as rig equipment operation, maintenance, and emergency response procedures. Provide specific examples from your previous experience to illustrate your capabilities.

2. Safety and Compliance

Emphasize your commitment to safety and compliance with industry regulations. Discuss your understanding of safety protocols and your role in maintaining a safe work environment.

3. Teamwork and Communication

Oil Riggers work closely with a diverse team in a demanding and often hazardous environment. Showcase your ability to collaborate effectively, communicate clearly, and foster a positive team atmosphere.

4. Physical Fitness and Endurance

Highlight your physical fitness and endurance, as Oil Riggers often work long hours in physically demanding conditions. Describe your experience working in challenging environments and your ability to maintain focus and productivity under pressure.

5. Career Goals and Motivation

Explain your reasons for pursuing an Oil Rigger position and how it aligns with your career goals. Express your passion for the industry and your desire to contribute to the safe and efficient production of oil and gas.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Oil Rigger role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.