Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oil Separator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

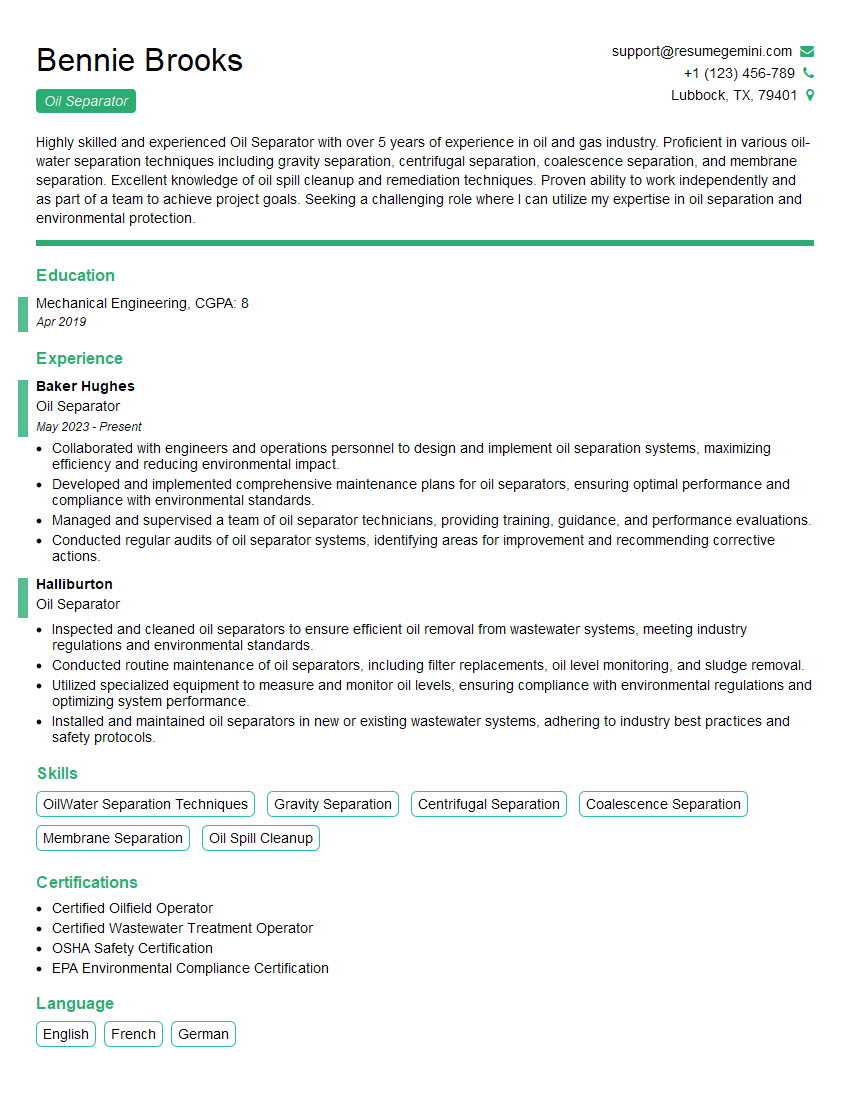

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Separator

1. Explain the working principle of an oil separator?

An oil separator works on the principle of gravity separation. The mixture of oil and water is introduced into the separator, where it is allowed to settle due to gravity. The oil, being lighter than water, rises to the top of the separator, while the water settles at the bottom. The separated oil can then be collected from the top of the separator, while the water is drained from the bottom.

2. What are the different types of oil separators?

Gravity Separators

- API Separators

- Parallel Plate Separators

- Tilted Plate Separators

Coalescing Separators

- Media Coalescers

- Electrostatic Coalescers

3. What are the factors that affect the efficiency of an oil separator?

- Oil droplet size

- Specific gravity of oil and water

- Flow rate

- Temperature

- Separator design

4. What are the applications of oil separators?

- Industrial wastewater treatment

- Oil spill cleanup

- Automotive industry

- Food processing industry

- Oil and gas industry

5. What are the maintenance requirements for an oil separator?

- Regular inspection and cleaning

- Replacement of coalescing media or electrostatic grids

- Monitoring of oil and water levels

- Calibration of alarms and controls

6. What are the common problems associated with oil separators and how can they be resolved?

- Oil carryover: This can be caused by high flow rates, small oil droplets, or poor maintenance. Possible solutions include increasing the separator size, using coalescing media, or optimizing the operating conditions.

- Water carryover: This can be caused by low flow rates, large oil droplets, or poor design. Possible solutions include reducing the separator size, using gravity separators, or installing a coalescer.

- Sludge accumulation: This can be caused by high solids content in the influent or poor maintenance. Possible solutions include regular cleaning, using a sludge removal system, or optimizing the influent conditions.

7. What are the latest advancements in oil separator technology?

- Dissolved air flotation (DAF): This technology uses air bubbles to float oil droplets to the surface, which are then skimmed off.

- Electrocoagulation: This technology uses an electrical current to destabilize oil droplets and promote coalescence.

- Membrane filtration: This technology uses a semi-permeable membrane to separate oil from water.

8. How do you determine the size of an oil separator that is required for a specific application?

- Determine the flow rate of the influent.

- Determine the concentration of oil in the influent.

- Select a separator that has a removal efficiency that is sufficient for the required application.

- Calculate the required separator volume based on the flow rate and removal efficiency.

9. What are the environmental regulations that apply to oil separators?

- Clean Water Act (CWA): This act regulates the discharge of pollutants into surface waters, including oil.

- Resource Conservation and Recovery Act (RCRA): This act regulates the handling and disposal of hazardous waste, including oil.

- National Pollutant Discharge Elimination System (NPDES): This program regulates the discharge of pollutants from industrial facilities into surface waters.

10. What are the career opportunities for oil separator professionals?

- Oil separator design engineer

- Oil separator sales engineer

- Oil separator maintenance technician

- Oil separator inspector

- Oil separator researcher

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Separator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Separator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oil Separators are responsible for ensuring that oil and water are separated before being discharged into the environment. Their duties include monitoring and maintaining oil-water separators, identifying and resolving separator issues, and ensuring compliance with environmental regulations.

1. Monitoring and Maintaining Oil-Water Separators

Oil Separators monitor and maintain oil-water separators to ensure they are operating efficiently and effectively.

- Conduct regular inspections and maintenance of oil-water separators

- Check and adjust separator levels and flows

- Clean and replace separator components as needed

2. Troubleshooting and Resolving Separator Issues

Oil Separators troubleshoot and resolve separator issues to ensure they are operating correctly.

- Identify and diagnose separator issues

- Repair or replace faulty separator components

- Adjust separator settings to optimize performance

3. Ensuring Compliance with Environmental Regulations

Oil Separators ensure compliance with environmental regulations to protect the environment.

- Monitor and report on separator performance

- Maintain records of separator maintenance and inspections

- Coordinate with regulatory agencies as needed

4. Other Duties

Oil Separators may also perform other duties as assigned, such as:

- Conducting training on separator operation and maintenance

- Participating in spill response and cleanup activities

- Maintaining a clean and safe work area

Interview Tips

Preparing for an Oil Separator interview can help you present yourself confidently and increase your chances of success. Here are some tips to help you prepare:

1. Research the Company and Position

Before the interview, research the company and the specific Oil Separator position you are applying for. This will help you understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website

- Read industry news and articles

- Connect with current or former employees on LinkedIn

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” Practicing your answers to these questions will help you feel more confident and prepared during the interview.

- Use the STAR method to answer behavioral questions

- Tailor your answers to the specific job requirements

- Be prepared to talk about your experience and skills

3. Highlight Your Relevant Experience and Skills

In your interview, be sure to highlight your relevant experience and skills that make you a good fit for the Oil Separator position. This includes your experience with oil-water separators, your troubleshooting skills, and your knowledge of environmental regulations.

- Quantify your accomplishments whenever possible

- Use specific examples to demonstrate your skills

- Be enthusiastic and positive about your experience

4. Ask Questions

At the end of the interview, be sure to ask questions to show your interest in the position and the company. This is also an opportunity to learn more about the company and the role.

- Ask about the company’s culture and values

- Ask about the specific responsibilities of the Oil Separator position

- Ask about the company’s plans for the future

Next Step:

Now that you’re armed with the knowledge of Oil Separator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Oil Separator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini