Are you gearing up for a career in Oil Spreader Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Oil Spreader Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

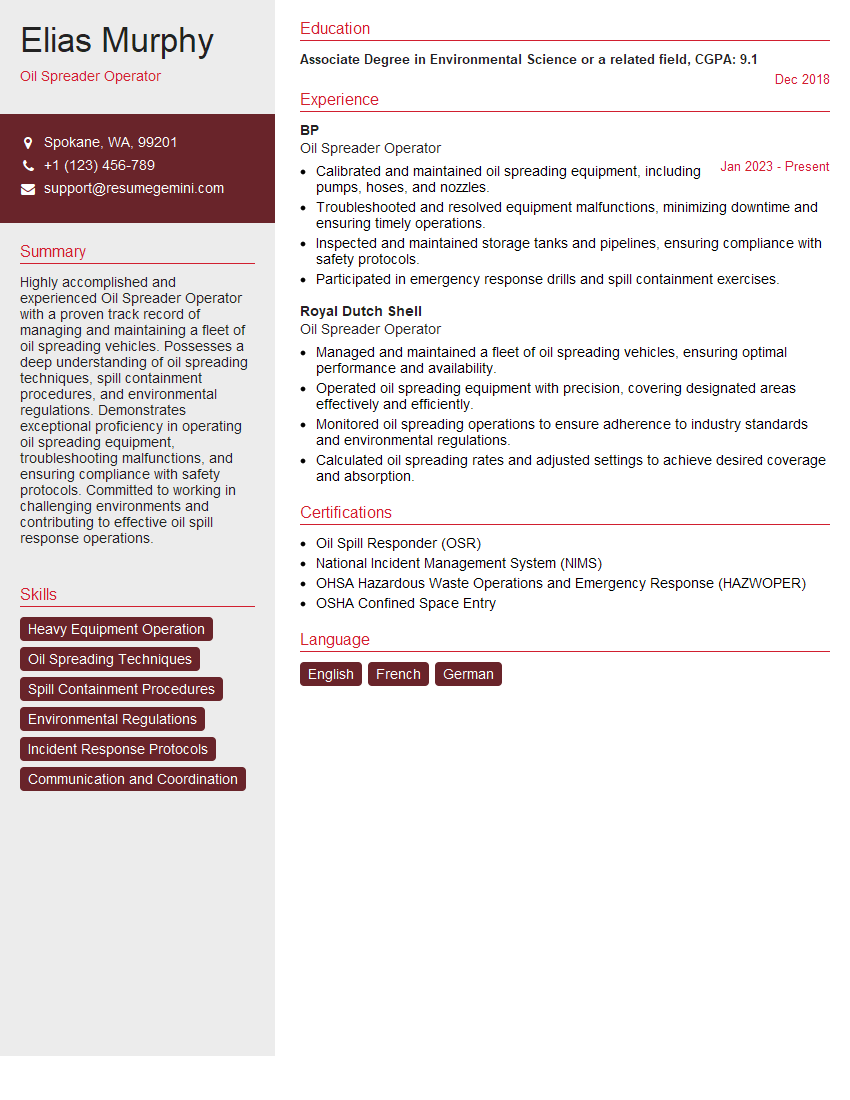

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Spreader Operator

1. What are the key responsibilities of an Oil Spreader Operator?

As an Oil Spreader Operator, I would be responsible for the safe and efficient operation of the oil spreading equipment. This would include:

- Setting up and calibrating the equipment according to specifications.

- Monitoring the spreading process and making adjustments as needed.

- Cleaning and maintaining the equipment.

- Following all safety procedures.

2. How do you ensure the accuracy of the oil spread rate?

Calibration and Maintenance

- Regularly calibrating the spreader according to the manufacturer’s specifications.

- Inspecting and maintaining the equipment to prevent any malfunctions or inaccuracies.

Monitoring and Adjustments

- Continuously monitoring the spreading process to ensure the desired spread rate is being achieved.

- Making necessary adjustments to the equipment or application parameters to maintain accuracy.

3. What are the different types of oils that can be spread using the equipment?

The type of oil that can be spread using the equipment will depend on the specific make and model of the spreader. However, some common types of oils that can be spread include:

- Asphalt

- Emulsions

- Sealers

- Tack coats

4. What safety precautions should be taken when operating oil spreading equipment?

- Wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a respirator.

- Ensuring the equipment is in good working order and properly maintained.

- Following all manufacturer’s instructions and safety guidelines.

- Being aware of the surrounding environment and potential hazards.

- Never operating the equipment under the influence of drugs or alcohol.

5. How do you troubleshoot common problems that may arise with oil spreading equipment?

- Identifying the source of the problem by observing symptoms and checking equipment components.

- Consulting the manufacturer’s manual or seeking guidance from experienced operators.

- Performing basic troubleshooting steps such as checking fluid levels, inspecting hoses, and cleaning filters.

- Reporting major issues to a supervisor or qualified mechanic for further assistance.

6. What is the importance of proper nozzle selection and adjustment for oil spreading?

- Ensuring the desired spread pattern and droplet size for the specific application.

- Optimizing the efficiency and effectiveness of the oil spreading process.

- Preventing over-application or uneven distribution of oil.

- Reducing waste and minimizing environmental impact.

7. How do you calculate the volume of oil required for a given spreading area?

- Determining the desired spread rate in gallons per square yard.

- Measuring or estimating the area to be covered in square yards.

- Multiplying the spread rate by the area to calculate the total volume of oil required.

- Considering factors such as application method, soil conditions, and weather conditions.

8. What are the environmental regulations and best practices related to oil spreading operations?

- Understanding and complying with local, state, and federal regulations regarding oil handling and disposal.

- Minimizing spills and leaks by following proper storage and transportation procedures.

- Using environmentally friendly oils and additives when possible.

- Properly disposing of waste oil and cleaning materials.

9. How do you maintain a clean and organized work area while operating oil spreading equipment?

- Regularly cleaning the equipment, including nozzles, hoses, and tanks.

- Storing equipment and materials in a designated and organized area.

- Preventing spills and leaks by using proper containment measures.

- Disposing of waste materials properly and in accordance with regulations.

10. How do you prioritize tasks and manage your time effectively when operating oil spreading equipment?

- Assessing the importance and urgency of tasks.

- Creating a work plan and allocating time accordingly.

- Delegating tasks to others when appropriate.

- Monitoring progress and making adjustments as needed.

- Communicating effectively with supervisors and colleagues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Spreader Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Spreader Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Oil Spreader Operator plays a vital role in optimizing pavement quality and ensuring road safety. Their key responsibilities include:

1. Oil Spreading

Controlling and operating equipment to spread oil evenly and precisely on designated road surfaces

2. Equipment Maintenance

Performing regular inspections, maintenance, and repairs on all assigned equipment, including trucks, pumps, and spreaders

3. Safety Compliance

Adhering to strict safety regulations and operating protocols to minimize risks and ensure the safety of themselves and others

4. Recordkeeping

Maintaining accurate records of oil quantities, spread rates, and equipment performance for compliance and quality control purposes

Interview Tips

To ace an interview for an Oil Spreader Operator position, it’s crucial to demonstrate your technical expertise, safety consciousness, and attention to detail. Here are some tips to help you prepare:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and industry trends to showcase your interest and knowledge

2. Highlight Your Technical Skills

Emphasize your proficiency in oil spreading equipment operation, maintenance, and troubleshooting

3. Demonstrate Safety Awareness

Discuss your understanding of safety regulations and your commitment to ensuring a safe work environment

4. Show Attention to Detail

Provide examples of your meticulousness and accuracy in performing tasks, such as maintaining records or calibrating equipment

Next Step:

Now that you’re armed with the knowledge of Oil Spreader Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Oil Spreader Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini