Feeling lost in a sea of interview questions? Landed that dream interview for Oil Treater but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Oil Treater interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

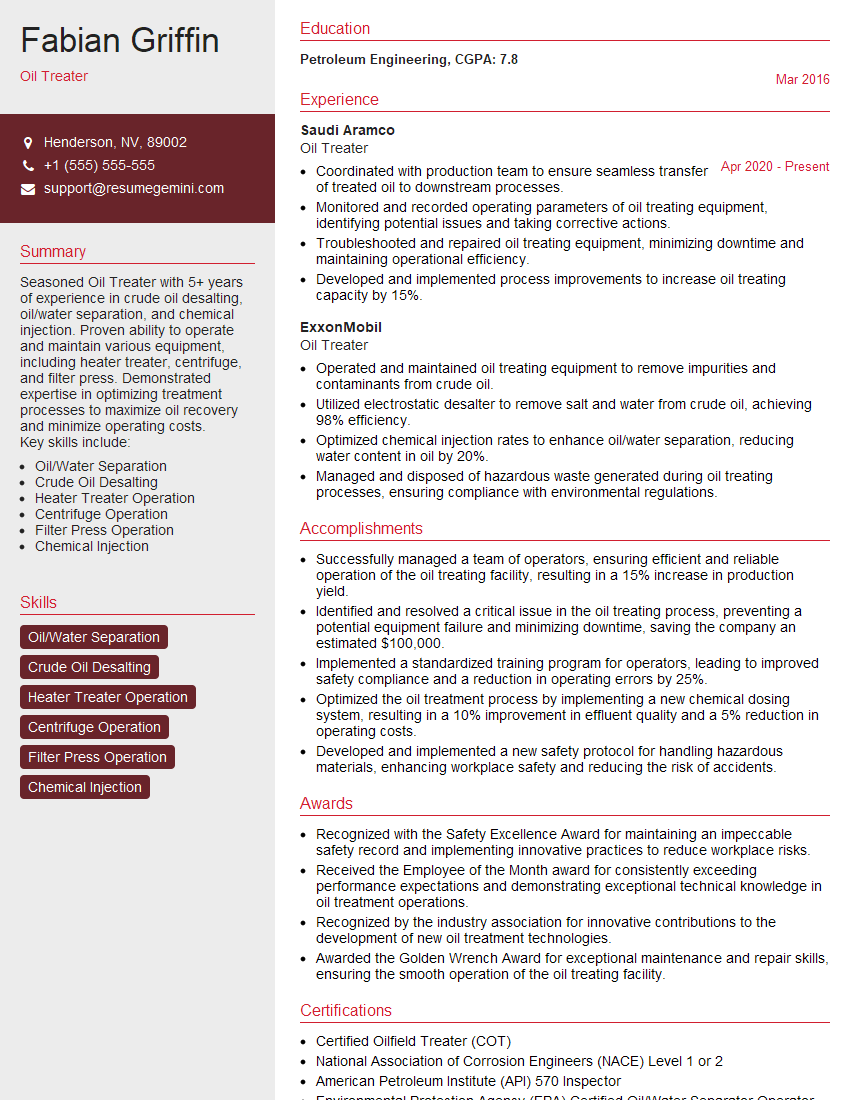

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Treater

1. What is the purpose of an oil treater?

The primary purpose of an oil treater is to separate oil from water and solids, removing impurities and contaminants to produce clean oil that meets industry standards. It is widely used in the oil and gas industry as a crucial step in oil processing and refining.

2. Describe the different types of oil treaters.

Gravity-Based Separators

- Horizontal separators: Utilize gravity to separate oil and water based on density difference.

- Vertical separators: Similar to horizontal separators, but with an upright configuration.

Electrostatic Separators

- Electrostatic coalescers: Apply an electric field to enhance the coalescence of small oil droplets into larger ones.

- Electrostatic precipitators: Employ a high-voltage electric field to remove fine solids and water droplets from oil.

Chemical Separators

- Chemical demulsifiers: Utilize chemicals to break down emulsions and promote oil-water separation.

- Chemical flocculants: Add chemicals to agglomerate small solids and aid in their removal.

3. How do you determine the optimum operating conditions for an oil treater?

- Analyze the characteristics of the crude oil, including its composition, viscosity, and temperature.

- Conduct pilot tests or rely on empirical data to establish optimal flow rates, inlet pressures, and chemical dosages.

- Monitor the treated oil quality and adjust operating parameters as needed to achieve desired specifications.

4. What are the common problems encountered in oil treater operations and how do you troubleshoot them?

- Emulsion formation: Address by adjusting chemical dosages, optimizing flow rates, or introducing additional mixing devices.

- Incomplete separation: Check for proper operating conditions, verify chemical compatibility, and consider adjusting the treater’s internals.

- Fouling: Implement regular cleaning and maintenance schedules, optimize chemical dosages, and inspect for any blockages or restrictions.

5. Describe the safety precautions that need to be taken when working with oil treaters.

- Wear appropriate personal protective equipment (PPE) including gloves, safety glasses, and protective clothing.

- Handle chemicals carefully, follow manufacturer’s instructions, and dispose of them properly.

- Be aware of potential hazards such as fire, explosion, and chemical spills.

- Receive proper training on safe operating procedures and emergency response protocols.

6. How do you maintain and calibrate an oil treater to ensure its optimal performance?

- Regularly clean and inspect the treater, its internals, and associated equipment.

- Calibrate instrumentation, such as pressure gauges and flow meters, to ensure accurate readings.

- Monitor and adjust chemical injection systems to optimize performance.

- Maintain proper operating conditions and troubleshoot any issues promptly.

7. What is the importance of monitoring and recording treater performance data?

- Process optimization: Track operating parameters and oil quality data to identify areas for improvement and fine-tune treater settings.

- Troubleshooting: Analyze historical data to diagnose problems and identify trends that may indicate potential issues.

- Compliance: Maintain records of treater operations to meet regulatory requirements and industry best practices.

8. What are the emerging technologies in oil treater design and operation?

- Advanced control systems: Utilize automation and data analytics to optimize treater performance and reduce manual intervention.

- Membrane separation: Employ semi-permeable membranes to remove dissolved solids and enhance oil-water separation.

- Nano-based technologies: Explore the use of nanomaterials to improve emulsion breaking and separation efficiency.

9. How do you stay up-to-date with the latest advancements and best practices in oil treater technology?

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Consult with experts and vendors in the field.

- Participate in professional organizations.

10. How do you prioritize and manage multiple responsibilities as an oil treater operator?

- Prioritize tasks: Identify critical activities and focus on completing them first.

- Time management: Utilize scheduling techniques and task lists to allocate time effectively.

- Delegate responsibilities: Assign tasks to other team members when appropriate to distribute workload.

- Effective communication: Keep supervisors and colleagues informed of progress and any challenges encountered.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Treater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Treater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oil Treaters are responsible for operating and maintaining equipment that separates oil, water, and solids from produced fluids. They ensure that the treated fluids meet environmental regulations and company specifications.

1. Operate and Maintain Equipment

Operate and maintain oil treating equipment, such as separators, filters, and pumps.

- Monitor equipment performance and make adjustments as needed.

- Troubleshoot and repair equipment malfunctions.

2. Test and Analyze Fluids

Collect and test fluid samples to determine their composition and properties.

- Analyze test results and make recommendations for treatment adjustments.

- Ensure that treated fluids meet environmental regulations and company specifications.

3. Manage Chemicals

Manage the use of chemicals in the oil treating process.

- Order and store chemicals.

- Mix and apply chemicals according to specifications.

4. Maintain Records

Maintain accurate records of oil treating operations.

- Record equipment operating parameters and fluid test results.

- Prepare reports on oil treating operations.

Interview Tips

Preparing for an interview for an Oil Treater position can help you make a good impression and increase your chances of getting the job. Here are some tips to help you ace the interview:

1. Research the Company

Before the interview, take some time to research the company you are applying to. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website.

- Read news articles and press releases about the company.

- Follow the company on social media.

2. Practice Your Answers

Take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Think about your experience and skills.

- Identify your strengths and weaknesses.

- Prepare examples of your work.

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing excessive jewelry or perfume/cologne.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Avoid wearing excessive jewelry or perfume/cologne.

4. Be On Time

Punctuality is important, so make sure to arrive for your interview on time. If you are running late, be sure to call or email the interviewer to let them know.

- Plan your route ahead of time.

- Allow extra time for traffic or unexpected delays.

- If you are running late, be sure to call or email the interviewer to let them know.

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not.

- Be honest about your experience and skills.

- Show your personality and enthusiasm.

- Be confident in your abilities.

Additional Tips

- Bring a copy of your resume and portfolio.

- Be prepared to answer questions about your experience, skills, and goals.

- Ask questions about the position and the company.

- Thank the interviewer for their time.

- Follow up with a thank-you note after the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oil Treater interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.