Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Oil Well Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Oil Well Engineer so you can tailor your answers to impress potential employers.

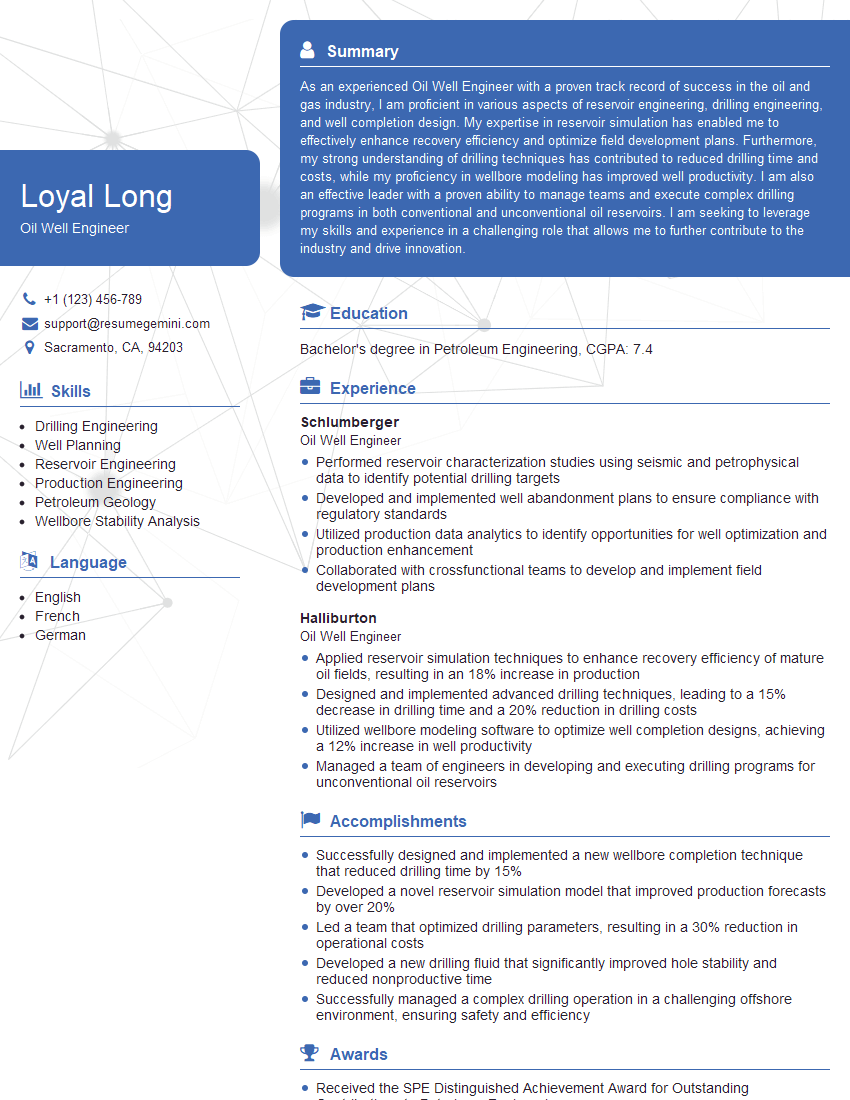

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Well Engineer

1. Describe the key elements of a successful well completion design.

The key elements of a successful well completion design include:

- Selecting the appropriate casing and tubing sizes and grades

- Designing the cementing program to ensure proper zonal isolation

- Selecting the appropriate production equipment, including the wellhead, Christmas tree, and artificial lift system

- Designing the completion to meet the specific requirements of the reservoir and the production goals

- Ensuring that the completion is safe and environmentally sound

2. How do you determine the optimum production rate for a given well?

The optimum production rate for a given well is determined by considering the following factors:

- The reservoir characteristics, including the porosity, permeability, and fluid properties

- The wellbore characteristics, including the casing size, tubing size, and artificial lift system

- The surface facilities, including the flowline, separator, and storage tanks

- The economic factors, including the operating costs and the desired rate of return

Factors affecting Optimum Production Rate

- Reservoir pressure

- Permeability of the reservoir

- Viscosity of the produced fluids

- Gas-oil ratio

- Water cut

- Artificial lift method

3. What are the different types of artificial lift systems, and when are they used?

The different types of artificial lift systems include:

- Gas lift: Used to lift fluids from the wellbore by injecting gas into the annulus

- Electric submersible pump (ESP): Used to lift fluids from the wellbore using a submersible pump driven by an electric motor

- Rod lift: Used to lift fluids from the wellbore using a sucker rod string connected to a surface pump

- Hydraulic lift: Used to lift fluids from the wellbore using a hydraulic pump driven by a surface power unit

- Plunger lift: Used to lift fluids from the wellbore using a plunger that is raised and lowered by a surface gas pressure

4. How do you design a cementing program for a given well?

To design a cementing program for a given well, the following steps are typically followed:

- Determine the objectives of the cementing job

- Select the appropriate cement slurry

- Calculate the volume of cement required

- Design the displacement program

- Prepare the well for cementing

- Pump the cement slurry

- Wait on cement (WOC)

- Drill out the cement

5. What are the different types of well testing methods, and when are they used?

The different types of well testing methods include:

- Drill stem test (DST): Used to evaluate the productivity of a reservoir

- Production test: Used to measure the production rate and fluid properties of a well

- Injection test: Used to evaluate the injectivity of a well

- Falloff test: Used to measure the reservoir pressure and permeability

- Buildup test: Used to measure the reservoir pressure and permeability

6. What are the different types of well logs, and what information do they provide?

The different types of well logs include:

- Open hole logs: Provide information about the formation lithology, porosity, and fluid content

- Cased hole logs: Provide information about the casing and cement bond

- Production logs: Provide information about the flow of fluids in the wellbore

- Geochemical logs: Provide information about the elemental composition of the formation

7. How do you interpret well log data to determine the formation properties?

To interpret well log data to determine the formation properties, the following steps are typically followed:

- Identify the different types of logs available

- Calibrate the logs to the appropriate depth

- Identify the different formations and lithologies

- Estimate the porosity and permeability of the formations

- Estimate the fluid content of the formations

- Identify any potential production zones

8. How do you design a workover program for a given well?

To design a workover program for a given well, the following steps are typically followed:

- Identify the objectives of the workover

- Select the appropriate equipment and materials

- Plan the workover procedure

- Prepare the well for workover

- Perform the workover

- Complete the well after workover

9. What are the different types of drilling fluids, and when are they used?

The different types of drilling fluids include:

- Water-based drilling fluids: Used in most drilling operations

- Oil-based drilling fluids: Used in drilling operations where water-based drilling fluids are not suitable

- Synthetic-based drilling fluids: Used in drilling operations where oil-based drilling fluids are not suitable

10. How do you design a drilling program for a given well?

To design a drilling program for a given well, the following steps are typically followed:

- Determine the objectives of the drilling program

- Select the appropriate drilling rig

- Select the appropriate drilling fluids

- Design the drilling procedure

- Prepare the well for drilling

- Drill the well

- Complete the well after drilling

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Well Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Well Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Oil Well Engineers are responsible for the design, construction, and maintenance of oil wells. They work closely with geologists and other engineers to identify potential drilling sites, develop drilling plans, and ensure that wells are drilled safely and efficiently. Some of the key job responsibilities of an Oil Well Engineer include:

1. Design and planning

Oil Well Engineers design and plan the construction of oil wells. They determine the optimal location for the well, the type of drilling rig to use, and the drilling methods to be employed.

- Designing and planning the construction of oil wells

- Determining the optimal location for the well

- Selecting the type of drilling rig to use

- Determining the drilling methods to be employed

2. Drilling and completion

Oil Well Engineers oversee the drilling and completion of oil wells. They work with drilling crews to ensure that the well is drilled according to plan and that it is completed safely and efficiently.

- Supervising the drilling and completion of oil wells

- Working with drilling crews to ensure that the well is drilled according to plan

- Ensuring that the well is completed safely and efficiently

3. Production and maintenance

Oil Well Engineers are responsible for the production and maintenance of oil wells. They monitor the performance of wells and make adjustments to ensure that they are producing oil and gas efficiently. They also perform maintenance on wells to keep them in good working condition.

- Monitoring the performance of wells

- Making adjustments to ensure that wells are producing oil and gas efficiently

- Performing maintenance on wells to keep them in good working condition

4. Safety and environmental compliance

Oil Well Engineers must ensure that their work is conducted in a safe and environmentally responsible manner. They must comply with all applicable safety and environmental regulations and they must take steps to minimize the impact of their work on the environment.

- Ensuring that work is conducted in a safe and environmentally responsible manner

- Complying with all applicable safety and environmental regulations

- Taking steps to minimize the impact of work on the environment

Interview Tips

Preparing for an interview for an Oil Well Engineer position can be daunting, but there are a few things that you can do to ace the interview:

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position that you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the position. You can also use this research to prepare questions to ask the interviewer.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

- Learn about the position you are applying for

2. Practice your answers to common interview questions

There are a number of common questions that you are likely to be asked in an interview for an Oil Well Engineer position. It is important to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- “Tell me about yourself.”

- “Why are you interested in this position?”

- “What are your strengths and weaknesses?”

- “What is your experience with oil well drilling and completion?”

- “What are your thoughts on the future of the oil and gas industry?”

3. Dress professionally and arrive on time

It is important to make a good first impression at your interview, so be sure to dress professionally and arrive on time. This shows the interviewer that you are serious about the position and that you respect their time.

- Wear a suit or business casual attire

- Arrive at the interview on time

- Be polite and respectful to everyone you meet

4. Be prepared to talk about your experience and skills

During the interview, you will be asked about your experience and skills. Be prepared to talk about your experience in oil well drilling and completion, as well as your other relevant skills. You should also be able to provide examples of your work.

- Be prepared to talk about your experience in oil well drilling and completion

- Provide examples of your work

- Highlight your skills and abilities

5. Be prepared to answer questions about the oil and gas industry

The interviewer may also ask you questions about the oil and gas industry. Be prepared to discuss your thoughts on the future of the industry and to provide your insights on current events.

- Be prepared to discuss your thoughts on the future of the oil and gas industry

- Provide your insights on current events

- Show that you are knowledgeable about the industry

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oil Well Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!