Feeling lost in a sea of interview questions? Landed that dream interview for Oil Well Gun Perforator Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Oil Well Gun Perforator Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

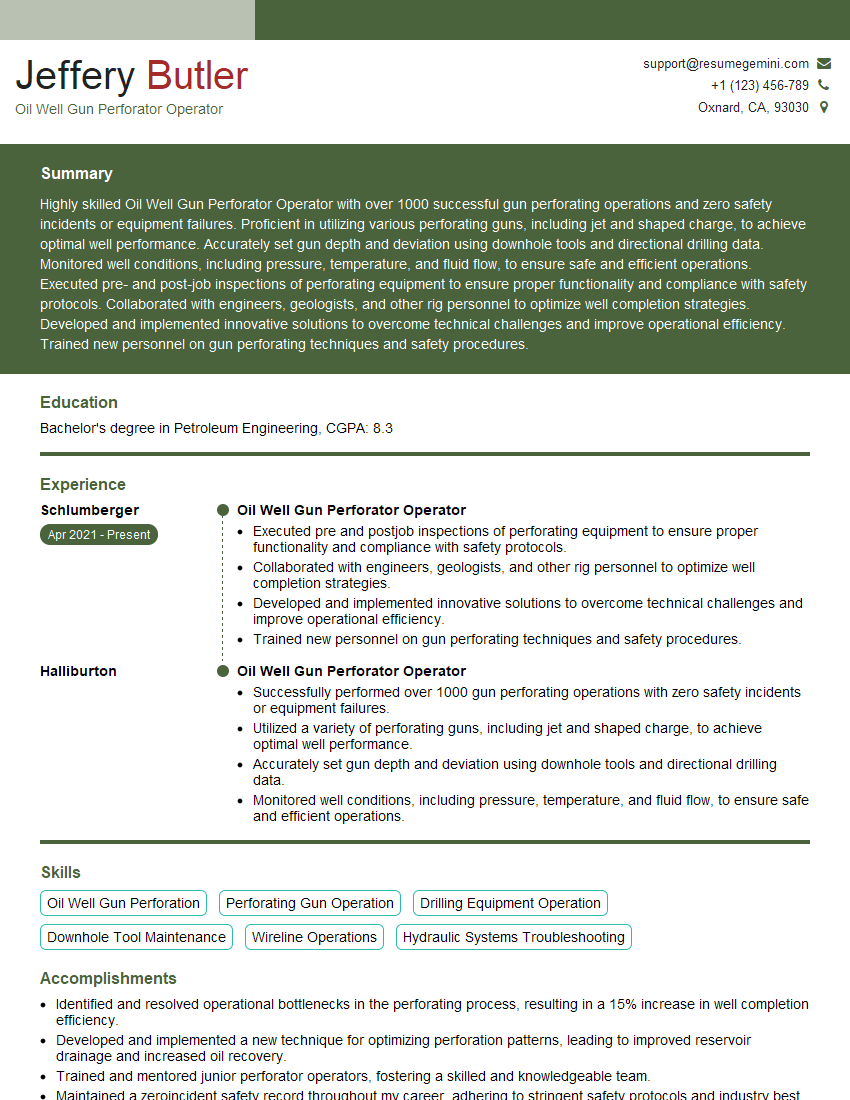

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Well Gun Perforator Operator

1. What is the purpose of a gun perforator in oil well operations?

- To create perforations in the casing and/or formation to allow fluid flow into the wellbore

- To enhance production or injection by establishing communication between the wellbore and the reservoir

2. Describe the components and principles of operation of a typical gun perforator.

- Contains the shaped charges and serves as a protection against explosion, pressure, and debris

- Explosive devices designed to create focused and high-energy jets to perforate the target

- Orientation and geometry of shaped charges can be adjusted for different perforation patterns

- Electrical or hydraulic system that initiates the detonation of shaped charges

- Ensures proper sequencing and timing of explosions

- Surface equipment that monitors and controls the perforating operation

- Provides communication between the operator and the downhole gun

Gun Housing:

Shaped Charges:

Initiation System:

Control Panel:

3. What factors influence the selection of the perforating system for a specific well?

- Wellbore conditions (pressure, temperature, fluid properties)

- Target formation characteristics (lithology, thickness)

- Perforation objectives (density, penetration depth)

- Wellbore trajectory (vertical, horizontal, deviated)

- Drilling and completion equipment

4. How do you determine the proper perforation pattern and shot density for a given application?

- Consider the reservoir characteristics, well completion strategy, and desired production/injection rate

- Use software or engineering models to calculate shot density, perforation depth, and spacing

- Take into account factors such as well spacing, reservoir thickness, and fluid viscosity

5. Describe the safety precautions that should be followed during perforating operations.

- Proper training and certification of personnel

- Use of appropriate personal protective equipment (PPE)

- Thorough well planning and risk assessment

- Careful handling and storage of explosives

- Communication and coordination with all involved parties

6. What are the potential complications that can occur during perforating operations?

- Premature detonation

- Misfiring or incomplete detonation

- Projectile debris in the wellbore

- Damage to the casing or formation

- Loss of borehole integrity

7. How do you troubleshoot and resolve perforating failures?

- Review wellbore data, gun performance, and operational procedures

- Analyze detonation logs and pressure measurements

- Consult with engineering and technical experts

- Consider alternative perforating methods or re-design of the perforation program

8. Describe the advancements and trends in gun perforating technology.

- Development of advanced shaped charges for increased penetration and perforation efficiency

- Use of downhole sensors and data acquisition for real-time monitoring and control

- Integration of perforation data with reservoir modeling and simulation

- Development of perforating systems for unconventional reservoirs, such as horizontal wells

9. What are the environmental considerations associated with gun perforating?

- Controlled detonation to minimize environmental impact

- Proper disposal of spent charges and explosive materials

- Compliance with environmental regulations and industry best practices

10. What are the personal qualities and skills required to be a successful Oil Well Gun Perforator Operator?

- Technical knowledge and understanding of perforating principles

- Strong attention to detail and safety awareness

- Ability to work independently and as part of a team

- Excellent communication and documentation skills

- Physical fitness and ability to work in challenging conditions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Well Gun Perforator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Well Gun Perforator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Oil Well Gun Perforator Operator plays a vital role in the oil and gas industry. Here are some key job responsibilities:

1. Rig Inspections and Equipment Setup

The operator is responsible for conducting thorough inspections of the oil rig and its equipment before any perforation operations commence. This includes checking the condition of the drilling rig, the gun perforator, and other associated tools to ensure they are in good working order.

- Inspect drilling rig and equipment for any potential hazards or malfunctions.

- Assemble and set up the gun perforator according to the well plan and safety protocols.

2. Gun Perforation Operations

The operator is responsible for carrying out gun perforation operations as per the well plan. This involves carefully positioning the gun perforator inside the wellbore and activating it to create perforations in the casing and formation.

- Control and monitor the gun perforator during the perforation process.

- Ensure accurate placement and depth of perforations to optimize well production.

3. Equipment Maintenance and Troubleshooting

The operator is responsible for maintaining the gun perforator and related equipment in good working condition. This involves performing regular maintenance checks, identifying and troubleshooting any issues, and making necessary repairs or adjustments.

- Conduct routine maintenance and inspections on the gun perforator and associated equipment.

- Troubleshoot any equipment malfunctions or operational issues and implement solutions.

4. Safety and Compliance

The operator is responsible for adhering to all safety regulations and industry standards while performing gun perforation operations. This includes following proper safety protocols, wearing appropriate personal protective equipment (PPE), and maintaining a clean and organized work area.

- Strictly adhere to safety protocols and regulations during all perforation operations.

- Wear appropriate PPE and maintain a safe work environment at all times.

Interview Tips

To ace an interview for an Oil Well Gun Perforator Operator position, candidates should consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, safety record, and industry reputation. Research the latest trends and technologies in oil and gas perforation to demonstrate your knowledge and interest in the field.

- Visit the company’s website and social media pages to gather information about their culture, values, and recent projects.

- Stay updated on industry news and advancements through trade publications and online resources.

2. Highlight Relevant Experience and Skills

Emphasize your experience in operating gun perforators, conducting well inspections, and maintaining oilfield equipment. Showcase your technical skills, such as proficiency in perforation techniques, equipment troubleshooting, and safety protocols.

- Quantify your accomplishments and provide specific examples of successful perforation operations you have conducted.

- Discuss your expertise in handling different types of gun perforators and equipment, and your ability to work independently and as part of a team.

3. Demonstrate Safety Consciousness and Compliance

Oil well perforation operations require strict adherence to safety protocols. Highlight your commitment to safety by discussing your experience in following industry regulations, maintaining a clean and organized work area, and using PPE.

- Explain your understanding of the potential hazards associated with perforation operations and your strategies for mitigating risks.

- Share examples of your proactive approach to safety, such as conducting thorough inspections, identifying potential issues, and implementing corrective actions.

4. Be Enthusiastic and Ask Questions

Show your enthusiasm for the position and the oil and gas industry. Ask thoughtful questions about the company’s operations, the specific role, and the opportunities for growth and development. This demonstrates your interest in the job and your desire to learn more.

- Express your passion for the field and your eagerness to contribute to the company’s success.

- Inquire about the company’s safety initiatives, training programs, and career advancement opportunities.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Oil Well Gun Perforator Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Oil Well Gun Perforator Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.