Are you gearing up for a career in Oil Well Perforator Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Oil Well Perforator Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

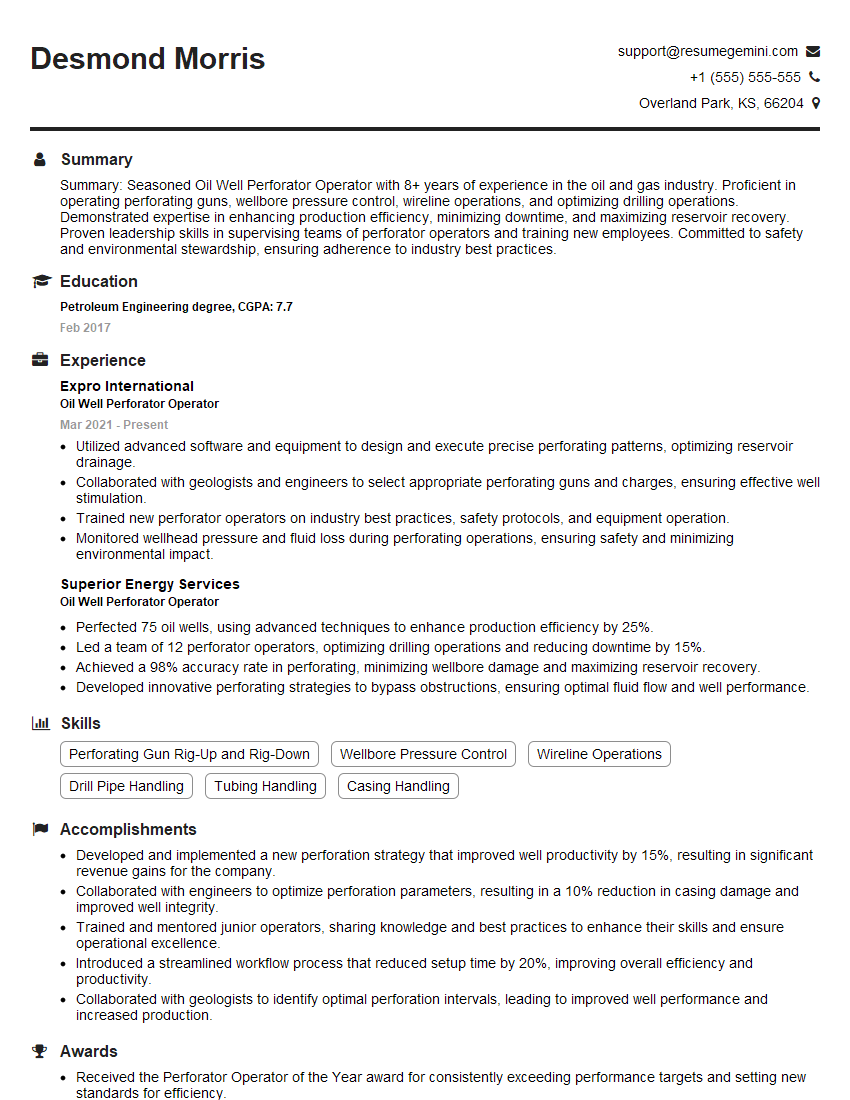

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oil Well Perforator Operator

1. What are the different types of perforating guns used in oil well perforation?

- Bullet guns: These are the most common type of perforating gun and use a shaped charge to create a perforation.

- Tubing-conveyed perforating guns: These guns are conveyed into the well on tubing and are used to perforate casing and tubing.

- Wireline-conveyed perforating guns: These guns are conveyed into the well on wireline and are used to perforate casing and tubing.

2. What are the key factors to consider when designing a perforation program?

- Wellbore conditions

- Formation characteristics

- Production goals

- Economic considerations

3. What are the different types of perforating fluids used, and what are their advantages and disadvantages?

- Oil-based fluids: These fluids are typically used in oil-bearing formations and have the advantage of providing good lubrication for the perforating gun.

- Water-based fluids: These fluids are typically used in water-bearing formations and have the advantage of being less expensive than oil-based fluids.

- Gas-based fluids: These fluids are typically used in gas-bearing formations and have the advantage of being able to penetrate deeper into the formation than other fluids.

4. What are the potential risks associated with perforation operations, and how can they be mitigated?

- Equipment failure

- Wellbore collapse

- Formation damage

- Blowouts

To mitigate these risks, it is important to:

- Use high-quality equipment

- Follow proper operating procedures

- Monitor the wellbore pressure and temperature closely

- Have a contingency plan in place in case of an emergency

5. How do you interpret well log data to determine the best perforation interval?

- First, I would look at the porosity and permeability logs to identify the zones that have the potential to produce hydrocarbons.

- Next, I would look at the gamma ray log to identify any shales or other impermeable zones that could act as barriers to flow.

- Finally, I would use the sonic log to determine the rock strength and select the perforation interval that is most likely to create a good connection between the wellbore and the formation.

6. How do you calculate the shot density and phasing for a perforation job?

- The shot density is the number of shots per foot of wellbore.

- The phasing is the spacing between the shots.

- The shot density and phasing are determined based on the formation characteristics, the production goals, and the type of perforating gun being used.

7. What are the different types of perforating charges, and what are their advantages and disadvantages?

- Shaped charges: These charges are designed to create a focused jet of high-pressure gas that penetrates the formation.

- Jet charges: These charges are designed to create a high-velocity jet of fluid that penetrates the formation.

- Gun charges: These charges are designed to create a large volume of gas that expands and fractures the formation.

Advantages and disadvantages:

- Shaped charges: High penetration, but can create a lot of formation damage.

- Jet charges: Lower penetration than shaped charges, but create less formation damage.

- Gun charges: Lowest penetration, but create the least formation damage.

8. How do you evaluate the success of a perforation job?

- The success of a perforation job is typically evaluated by the amount of hydrocarbons that are produced from the well.

- Other factors that can be used to evaluate the success of a perforation job include the penetration depth of the perforations, the number of perforations that were created, and the amount of formation damage that was created.

9. What are the latest trends in oil well perforation technology?

- The use of laser perforation

- The development of new perforating charges that create less formation damage

- The use of real-time monitoring to optimize perforation operations

10. What are the most important qualities of a successful Oil Well Perforator Operator?

- Attention to detail

- Strong technical skills

- Ability to work under pressure

- Teamwork skills

- Commitment to safety

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oil Well Perforator Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oil Well Perforator Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Oil Well Perforator Operator is a highly specialized individual responsible for operating perforating gun systems used to create perforations on oil well casings, allowing oil and gas to flow from the reservoir into the wellbore. Below are key job responsibilities of Oil Well Perforator Operator:

1. Well Perforation

Responsible for operating and maintaining equipment to perforate (create holes in) oil well casings to facilitate the inflow of oil or gas.

2. Gun Loading

Loads perforating guns with explosives and detonators, ensuring proper preparation and handling of sensitive materials.

3. Wellbore Inspection

Inspects oil wellbore equipment, such as drill bits, casing, and perforating guns, to ensure proper functioning and identify potential issues.

4. Pressure Maintenance

Monitors and adjusts pressure levels within the wellbore to ensure optimal flow rates without compromising safety.

5. Safety Management

Adheres strictly to all safety protocols, including the use of personal protective equipment, to maintain a safe work environment.

Interview Tips

To help candidates ace the interview for an Oil Well Perforator Operator position, here are some essential preparation tips:

1. Research the Company

Familiarize yourself with the company’s background, operations, and safety practices. This demonstrates your interest and preparedness.

2. Highlight Relevant Skills

Emphasize your proficiency in perforating gun systems, including loading, firing, and troubleshooting. Highlight your experience in handling explosives and maintaining wellbore pressure.

3. Showcase Safety Consciousness

Demonstrate your understanding of oilfield safety regulations and your commitment to maintaining a safe work environment. Share examples of your safety practices and certifications.

4. Practice Answering Common Questions

Prepare for common interview questions, such as “Describe your experience with perforating gun systems” and “How do you ensure wellbore safety during operations?” Research industry-specific terminology and demonstrate your technical knowledge.

5. Dress Professionally

Make a positive first impression by dressing professionally and adhering to company dress code guidelines. Wear appropriate safety gear if required.

6. Ask Informed Questions

Ask thoughtful questions that show your interest in the role and the company. Inquire about safety protocols, career advancement opportunities, or industry trends.

7. Be Confident and Enthusiastic

Display confidence and enthusiasm throughout the interview. Convey your passion for the oil and gas industry and your eagerness to contribute to the team’s success.

8. Showcase Your Physical Fitness

As the job requires physical exertion, emphasize your fitness and ability to work in demanding environments. Share examples of your physical endurance or training.

9. Network and Seek Endorsements

Connect with professionals in the oil and gas industry and seek endorsements from previous colleagues. Positive recommendations can strengthen your application.

10. Follow-Up

After the interview, send a thank-you note to the interviewers, reiterating your interest and key qualifications. Reiterate your commitment to safety and your eagerness to contribute to the company’s success.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Oil Well Perforator Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Oil Well Perforator Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.