Are you gearing up for an interview for a Open Die Inspector position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Open Die Inspector and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

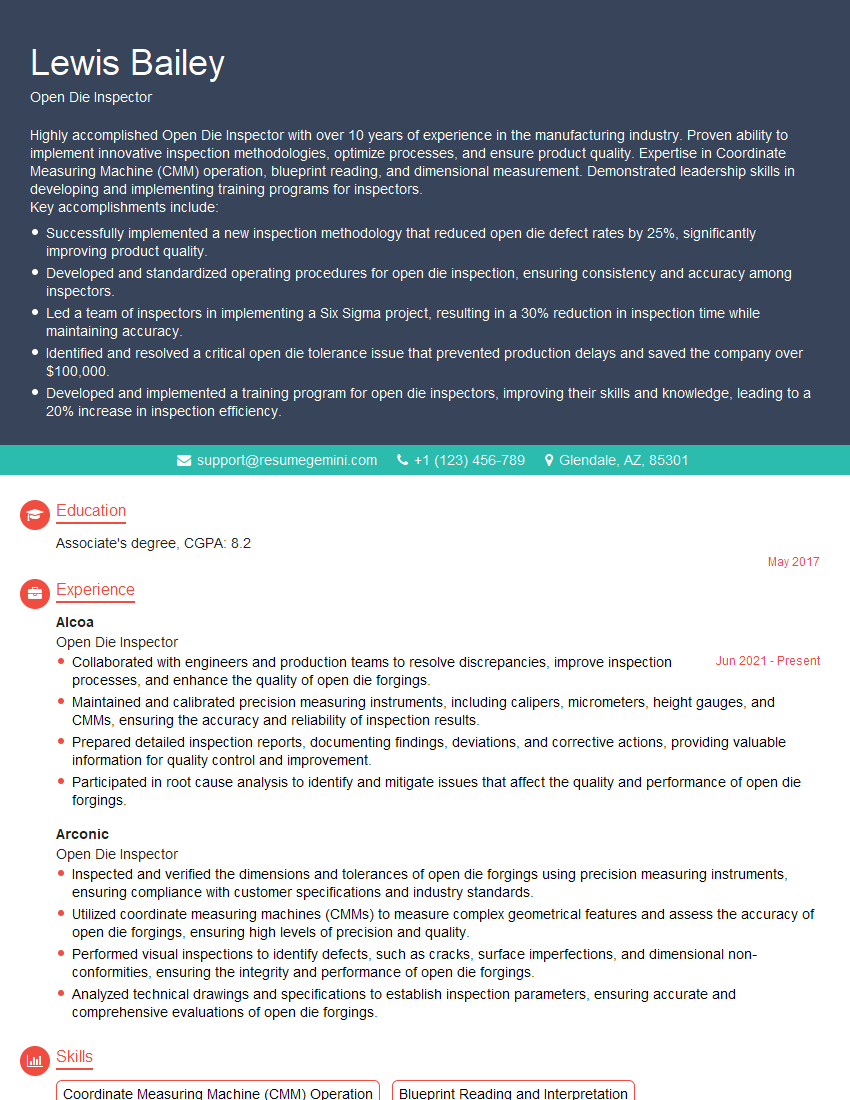

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Open Die Inspector

1. How do you perform visual inspection of open die forgings?

I begin by reviewing the engineering drawings and specifications to identify the critical dimensions and tolerances.

I use a magnifying glass, micrometers, and other precision measuring tools to inspect the forgings for:

- Dimensional accuracy

- Surface finish

- Cracks, porosity, and other defects

I also check for die wear and make recommendations for die maintenance or replacement.

2. What techniques do you use to measure the dimensions of open die forgings?

Manual Measurement

- Using micrometers, calipers, and rulers

- Measuring to the nearest thousandth of an inch or as specified in the drawing

Coordinate Measuring Machine (CMM)

- Using a CMM to measure complex shapes and features

- Collecting data points to create a 3D model of the forging

3. How do you ensure the accuracy of your measurements?

I follow established calibration procedures to ensure the accuracy of my measuring tools.

I use certified reference materials to verify the accuracy of my measurements.

I record all measurements in a traceable manner and maintain detailed inspection reports.

4. What types of defects can you identify during open die forging inspection?

- Dimensional errors

- Surface defects (e.g., cracks, porosity, scratches)

- Internal defects (e.g., inclusions, voids)

- Die wear

- Material non-conformities

5. How do you prioritize the severity of defects?

I prioritize defects based on the following criteria:

- Criticality of the component

- Size and location of the defect

- Potential impact on the performance or safety of the component

- Repairability of the defect

6. How do you report and document your findings?

I prepare detailed inspection reports that include:

- A description of the inspection methods used

- The inspection results, including measurements and defect identification

- Recommendations for corrective actions (if necessary)

I submit these reports to the appropriate personnel for review and action.

7. What is your experience with non-destructive testing (NDT) methods?

I have experience with the following NDT methods:

- Ultrasonic testing

- Magnetic particle testing

- Liquid penetrant testing

I use these methods to detect internal and surface defects in open die forgings.

8. What is your understanding of the American Society for Nondestructive Testing (ASNT) standards?

I am familiar with the ASNT standards for NDT personnel qualification and certification. I understand the importance of following these standards to ensure the accuracy and reliability of NDT inspections.

9. How do you stay up-to-date with the latest inspection techniques and technologies?

I attend industry conferences and seminars.

I read technical journals and articles.

I participate in training programs offered by equipment manufacturers.

10. What is your experience with quality management systems, such as ISO 9001?

I have experience working in organizations that are ISO 9001 certified.

I am familiar with the requirements of ISO 9001 and how they apply to the inspection process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Open Die Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Open Die Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Open Die Inspectors are responsible for ensuring that the open die forging process is carried out in accordance with specifications. Their duties are crucial for maintaining the quality of the forged products and preventing safety hazards.

1. Verifying raw materials and finished products

Inspectors examine the incoming raw materials, such as metal bars and billets, to ensure that they meet the required specifications in terms of dimensions, composition, and surface quality. They also inspect finished products to ensure that they conform to the customer’s requirements and industry standards. Inspectors use a variety of measuring instruments and testing equipment to perform these inspections.

2. Monitoring the forging process

Inspectors monitor the forging process to ensure that it is carried out in accordance with the established parameters. They observe the operation of the forging equipment, such as the presses, hammers, and dies, and make adjustments as needed to maintain optimal performance. Inspectors also monitor the temperature of the metal during forging to ensure that it is within the specified range.

3. Identifying and resolving defects

Inspectors identify and resolve defects in the forged products. They use their knowledge of the forging process and their experience in identifying defects to determine the cause of the problem and recommend corrective actions. Inspectors may also perform repairs on defective products if necessary.

4. Maintaining records and documentation

Inspectors maintain records and documentation related to the forging process, including inspection reports, quality control data, and maintenance records. They also participate in quality control meetings and training programs to stay up-to-date on the latest industry standards and best practices.

Interview Tips

Preparing for an interview for an Open Die Inspector position requires a combination of technical knowledge, industry experience, and interview skills. Here are some tips to help candidates ace their interview and land the job:

1. Research the company and the position

Before the interview, candidates should research the company and the specific Open Die Inspector position they are applying for. This includes learning about the company’s history, products, and services, as well as the specific responsibilities and requirements of the inspector position. Candidates should also review the company’s website, LinkedIn page, and other online resources to gain insights into the company’s culture and values.

2. Practice answering common interview questions

Candidates should practice answering common interview questions, such as “Tell me about yourself,” “Why are you interested in this position,” and “What are your strengths and weaknesses.” They should also prepare questions to ask the interviewer, which demonstrates their interest in the position and the company.

3. Highlight relevant skills and experience

In the interview, candidates should highlight their relevant skills and experience in open die forging. This includes their knowledge of the forging process, their experience in identifying and resolving defects, and their ability to maintain records and documentation. Candidates should also emphasize their attention to detail, their ability to work independently and as part of a team, and their commitment to quality.

4. Dress professionally and arrive on time

Candidates should dress professionally for the interview and arrive on time. This shows respect for the interviewer and the company. Candidates should also bring copies of their resume and references to the interview.

5. Follow up after the interview

After the interview, candidates should follow up with the interviewer by sending a thank-you note. This is an opportunity to reiterate their interest in the position and to thank the interviewer for their time.

Next Step:

Now that you’re armed with the knowledge of Open Die Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Open Die Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini