Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Open Hearth Helper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Open Hearth Helper so you can tailor your answers to impress potential employers.

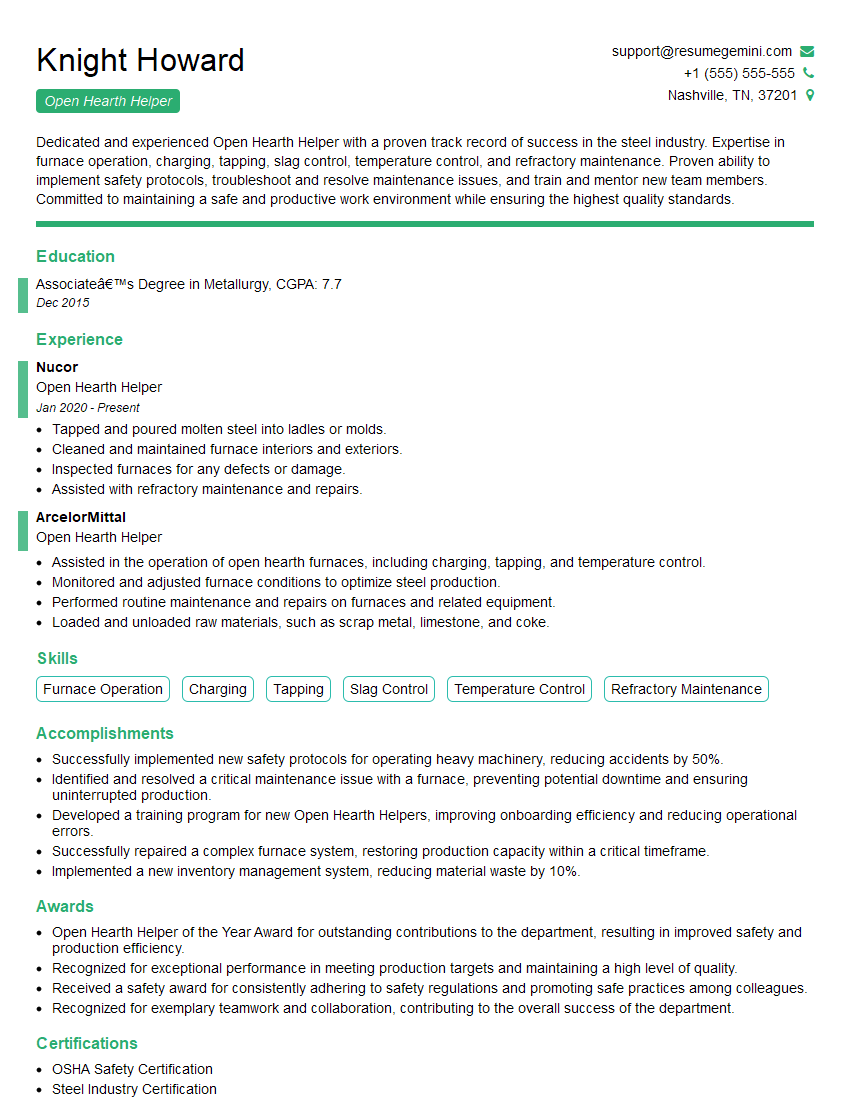

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Open Hearth Helper

1. Explain the role of an Open Hearth Helper in the steel-making process?

- Assists the Steelmaker in charging and operating the open-hearth furnace, including adding raw materials, adjusting temperature, and tapping the furnace.

- Monitors the furnace and controls operating conditions, ensuring that the steel is produced according to specifications.

- Performs maintenance and repairs on the furnace and related equipment, including replacing refractory lining, cleaning burners, and adjusting valves.

- Adheres to all safety regulations and procedures to ensure a safe work environment.

- May perform other tasks as assigned by the Steelmaker or supervisor.

2. What are the key skills and qualities required to be an effective Open Hearth Helper?

Technical Skills

- Knowledge of open-hearth furnace operations and metallurgy.

- Ability to operate and maintain furnace equipment.

- Experience in refractory maintenance and repair.

- Understanding of safety protocols and procedures.

Qualities

- Strong work ethic and attention to detail.

- Ability to work independently and as part of a team.

- Good communication and interpersonal skills.

- Physical stamina and ability to work in a hot and demanding environment.

3. Describe the typical work environment for an Open Hearth Helper?

- Works in a steel mill environment, which is typically hot, noisy, and dusty.

- May work in confined spaces and at heights.

- Operates heavy machinery and equipment.

- May be exposed to hazardous materials and fumes.

- Works in shifts, including nights, weekends, and holidays.

4. What are the career advancement opportunities for an Open Hearth Helper?

- Steelmaker

- Supervisor

- Metallurgist

- Quality Control Inspector

- Safety Manager

5. What are the challenges and rewards of being an Open Hearth Helper?

Challenges

- Working in a demanding and hazardous environment.

- Performing physically demanding tasks.

- Working in shifts, including nights, weekends, and holidays.

Rewards

- Job security in a stable industry.

- Opportunity to learn and develop skills in metallurgy and steelmaking.

- Competitive salary and benefits package.

- Sense of accomplishment from contributing to the production of steel.

6. What is your understanding of refractory materials and their importance in the open-hearth process?

- Refractory materials are non-metallic materials that can withstand high temperatures without melting or decomposing.

- They are used to line the open-hearth furnace to protect it from the corrosive effects of molten steel and slag.

- Proper selection and maintenance of refractory materials are critical to the efficient and safe operation of the furnace.

7. How do you ensure the safety of yourself and others while working in the open-hearth environment?

- Wear appropriate personal protective equipment, including a hard hat, safety glasses, gloves, and flame-resistant clothing.

- Follow all safety protocols and procedures, including lockout/tagout procedures.

- Be aware of your surroundings and potential hazards.

- Communicate clearly with coworkers and supervisors about potential hazards and safety concerns.

8. Describe your experience in troubleshooting and resolving issues that may arise during the open-hearth process?

- Example 1: Identified and repaired a leak in the furnace refractory, preventing further damage.

- Example 2: Adjusted burner settings to optimize combustion and reduce fuel consumption.

- Example 3: Assisted in troubleshooting and resolving a problem with the slag removal system, ensuring smooth furnace operation.

9. How do you maintain and calibrate the equipment used in the open-hearth process, such as temperature sensors and flow meters?

- Regularly inspect and clean sensors and flow meters to ensure accuracy and reliability.

- Follow calibration procedures and use appropriate calibration tools and standards.

- Document calibration results and maintain records for traceability.

- Identify and report any equipment malfunctions or calibration issues promptly.

10. What role does teamwork play in the successful operation of the open-hearth process?

- Teamwork is essential for safe and efficient furnace operation.

- Open Hearth Helpers must communicate effectively with each other, the Steelmaker, and other team members.

- They must be able to work together to solve problems and respond to unexpected situations.

- A strong team environment fosters a sense of trust and support among team members.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Open Hearth Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Open Hearth Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities for Open Hearth Helper

Open Hearth Helpers play a crucial role in the steel-making process by assisting in various operations within the Open Hearth Furnace (OHF) area.

1. Furnace Maintenance and Operation

Assist in maintaining and operating the OHF equipment, including burners, tapping systems, and refractory lining.

- Monitor furnace conditions and make adjustments as needed to ensure optimal operating efficiency.

- Perform inspections and minor repairs to furnace components to prevent breakdowns and maintain safety.

2. Material Handling

Assist in the handling of raw materials, such as scrap metal, limestone, and ore, used in the steel-making process.

- Operate cranes and other heavy equipment to move materials into and out of the OHF.

- Maintain inventory of materials and ensure sufficient supply for production.

3. Quality Control

Assist in monitoring and maintaining product quality by performing tests and inspections throughout the steel-making process.

- Collect samples and conduct basic quality checks on raw materials and finished steel products.

- Report any deviations from specifications to ensure timely corrective actions.

4. Safety and Housekeeping

Ensure a safe and clean work environment by adhering to established safety protocols and maintaining proper housekeeping.

- Wear appropriate protective gear and follow all safety procedures.

- Clean and maintain work areas to minimize hazards and prevent accidents.

Interview Tips for Acing the Open Hearth Helper Interview

To ace your interview for the Open Hearth Helper position, follow these tips and prepare thoroughly.

1. Research the Company and Position

Understand the company’s history, operations, and industry standing.

- Research the Open Hearth Furnace (OHF) process and its importance in steel-making.

- Familiarize yourself with the specific responsibilities outlined in the job description.

2. Highlight Relevant Experience and Skills

Emphasize your prior experience in operating furnaces, handling heavy equipment, or performing quality control tasks.

- Even if your previous experience was outside the steel industry, draw parallels and explain how your transferable skills apply to the role.

- Quantify your accomplishments with data or specific examples to demonstrate your impact.

3. Demonstrate Safety Awareness

Safety is paramount in the steel industry.

- Explain your understanding of industry-specific hazards and best practices.

- Highlight your commitment to adhering to safety procedures and maintaining a safe work environment.

4. Practice Your Answers

Prepare thoughtful responses to common interview questions.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Seek feedback from others to refine your answers and improve your delivery.

5. Dress Professionally and Arrive Punctually

Make a positive first impression by dressing appropriately and arriving on time.

- Wear clean, business-casual attire that reflects the professional nature of the role.

- Plan your route and allow ample time to account for traffic or unexpected delays.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Open Hearth Helper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.