Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Operations and Maintenance Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

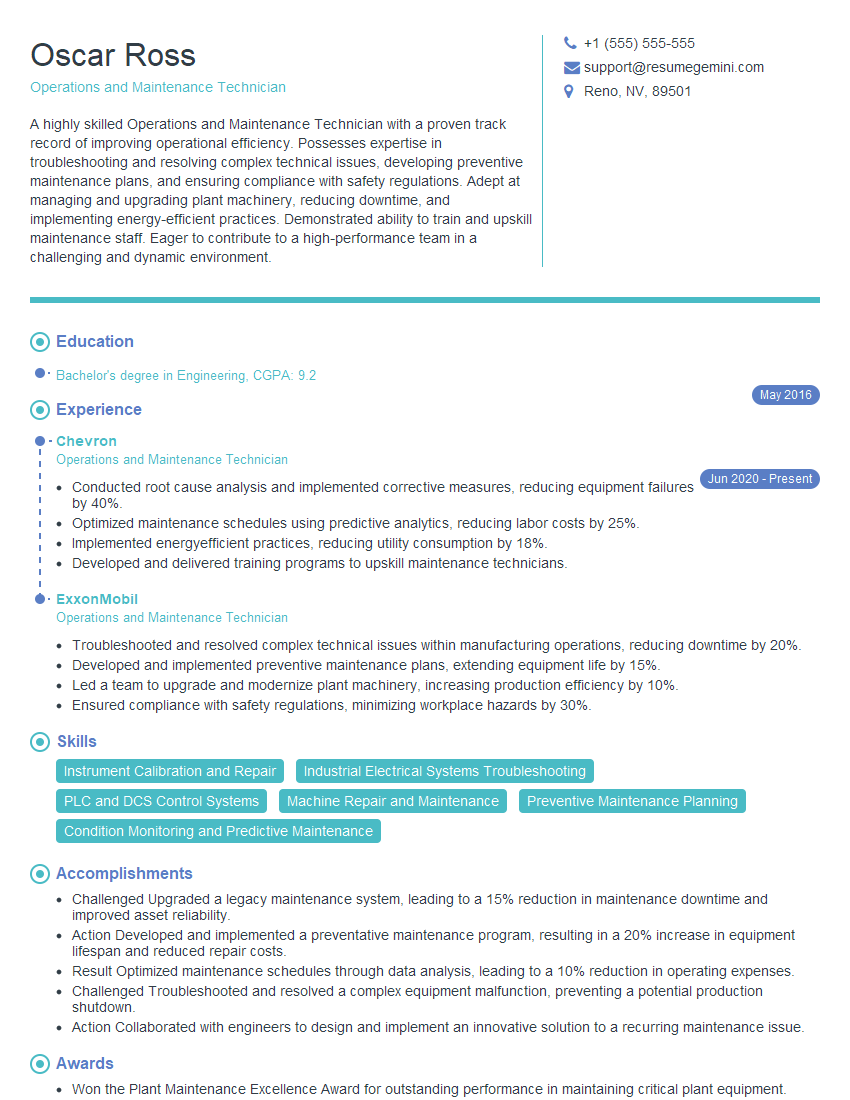

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Operations and Maintenance Technician

1. Describe the key responsibilities of an Operations and Maintenance Technician?

- Responsible for maintaining and repairing plant equipment, machinery, and facilities.

- Conducting preventive and corrective maintenance, troubleshooting, and repairs.

- Performing regular inspections, monitoring equipment performance, and identifying potential issues.

- Ensuring equipment is operating safely and efficiently.

- Coordinating with other departments to ensure smooth operation and maintenance of the facility.

2. What are the essential technical skills for an Operations and Maintenance Technician?

Electrical Skills

- Troubleshooting and repairing electrical systems, motors, and controls.

- Understanding electrical diagrams, schematics, and blueprints.

- Safe handling and testing of electrical equipment.

Mechanical Skills

- Disassembling, repairing, and assembling mechanical equipment.

- Understanding mechanical principles, such as hydraulics, pneumatics, and lubrication.

- Using precision measuring tools and instruments.

Instrumentation Skills

- Understanding the principles of instrumentation and control systems.

- Troubleshooting and calibrating sensors, transmitters, and controllers.

- Interpreting instrument readings and data.

3. How do you prioritize maintenance tasks when dealing with multiple issues?

- Assess the severity and urgency of each issue.

- Determine the potential impact on production or operations.

- Consider the availability of resources and the required expertise.

- Communicate with stakeholders to prioritize tasks and manage expectations.

- Delegate tasks to ensure timely completion.

4. Describe your experience in implementing preventive maintenance programs.

- Developed and implemented a comprehensive preventive maintenance schedule.

- Established equipment inspection and monitoring procedures.

- Trained staff on preventive maintenance techniques.

- Analyzed maintenance data to identify areas for improvement.

- Collaborated with suppliers to optimize spare parts inventory and ensure timely delivery.

5. How do you ensure that equipment is operating safely and efficiently?

- Conducting regular inspections and monitoring equipment performance.

- Following manufacturer’s guidelines and specifications.

- Enforcing safety protocols and procedures.

- Performing preventive maintenance to prevent breakdowns.

- Identifying and addressing potential hazards.

6. What are your strategies for troubleshooting and repairing complex equipment?

- Analyzing symptoms and identifying potential causes.

- Using diagnostic tools and techniques.

- Consulting with technical manuals and experts.

- Replacing or repairing faulty components.

- Testing and verifying repairs to ensure functionality.

7. Describe your experience in using computerized maintenance management systems (CMMS).

- Proficient in using CMMS software to track maintenance tasks.

- Managing work orders, scheduling, and tracking progress.

- Generating reports and analyzing maintenance data.

- Customizing CMMS to meet specific requirements.

- Training staff on CMMS usage.

8. How do you stay up-to-date with the latest industry trends and technologies?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and discussion groups.

- Collaborating with other professionals and vendors.

- Pursuing professional development opportunities.

9. What is your approach to working in a team environment?

- Collaborating with colleagues to achieve common goals.

- Sharing knowledge and expertise.

- Providing support and assistance to team members.

- Resolving conflicts and issues professionally.

- Maintaining a positive and productive work environment.

10. What are your strengths and weaknesses as an Operations and Maintenance Technician?

Strengths

- Strong technical skills in electrical, mechanical, and instrumentation systems.

- Proficient in troubleshooting and repairing complex equipment.

- Excellent problem-solving and analytical abilities.

- Ability to work independently and as part of a team.

- Committed to safety and efficiency.

Weaknesses

- Limited experience with specific industry-specific equipment.

- Desire to enhance leadership and management skills.

- Working on multiple projects simultaneously can sometimes be challenging.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Operations and Maintenance Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Operations and Maintenance Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Operations and Maintenance Technicians are responsible for ensuring the smooth and efficient operation of a wide range of systems, equipment, and facilities. Key job responsibilities include:

1. Maintenance and Repairs

Performing scheduled and unscheduled maintenance on equipment and systems to prevent breakdowns and ensure optimal performance.

- Inspecting equipment for potential problems and performing preventive maintenance tasks, such as cleaning, lubrication, and adjustments.

- Diagnosing and repairing equipment failures, including electrical, mechanical, and hydraulic systems.

2. Troubleshooting and Problem Solving

Identifying and resolving operational issues in a timely and efficient manner.

- Analyzing data and monitoring systems to identify potential problems before they become major issues.

- Troubleshooting equipment malfunctions and implementing corrective actions.

3. Operations and Monitoring

Ensuring the safe and efficient operation of equipment and systems.

- Monitoring equipment performance and operating parameters.

- Adjusting controls and settings to optimize performance.

4. Record Keeping and Documentation

Maintaining accurate records of maintenance activities and repairs.

- Documenting all maintenance and repair work performed.

- Maintaining an inventory of equipment and parts.

Interview Tips

To ace an interview for an Operations and Maintenance Technician position, candidates should consider the following tips:

1. Research the Company and Position

Before the interview, research the company and the specific position you’re applying for. This will help you understand the company’s culture, goals, and what they expect from their Operations and Maintenance Technicians.

- Visit the company’s website.

- Read industry news and articles.

- Connect with the company on social media.

2. Prepare Your Experience and Skills

Highlight your relevant experience and skills that match the job requirements. Quantify your accomplishments whenever possible using specific examples.

- Review the job description carefully.

- Identify the key skills and experience that the company is looking for.

- Prepare examples of your work that demonstrate your skills.

3. Practice Common Interview Questions

Practice answering common interview questions, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?”

- Prepare your answers to these questions in advance.

- Practice your answers out loud.

- Have a friend or family member ask you these questions.

4. Dress Professionally

First impressions matter, so dress professionally for your interview. This means wearing a suit or business casual attire.

- Choose clothes that are clean and pressed.

- Make sure your shoes are polished.

- Avoid wearing strong perfumes or colognes.

5. Be Confident and Enthusiastic

Confidence and enthusiasm will go a long way in an interview. Maintain eye contact, speak clearly, and project a positive attitude.

- Smile and greet the interviewer with a firm handshake.

- Answer questions confidently and enthusiastically.

- Ask questions about the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Operations and Maintenance Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!