Feeling lost in a sea of interview questions? Landed that dream interview for Operations Logistics Analyst but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Operations Logistics Analyst interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

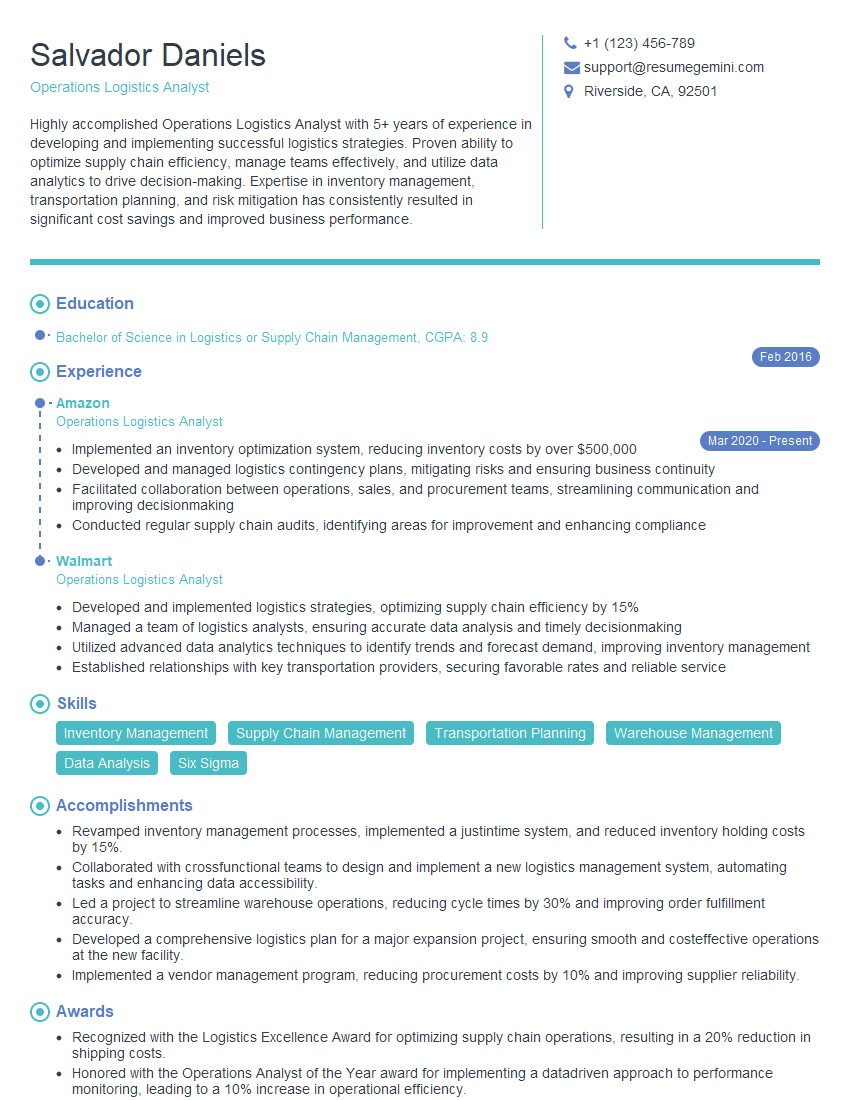

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Operations Logistics Analyst

1. What key metrics do you use to measure the efficiency of logistics operations?

The key metrics used to assess the effectiveness of logistics operations include:

- Order fulfillment rate: Percentage of orders delivered on time and in full.

- Inventory turnover: Measures how efficiently inventory is managed and utilized.

- Transportation costs: Total costs associated with transporting goods.

- Warehouse utilization: Percentage of warehouse space effectively utilized for storage.

- Customer satisfaction: Feedback on order accuracy, delivery timeliness, and overall experience.

2. How do you approach optimizing transportation routing and scheduling?

Real-time tracking and monitoring:

- Using GPS tracking devices to monitor vehicle locations and routes.

- Receiving live updates on traffic conditions and weather forecasts.

Route optimization algorithms:

- Employing mathematical models to determine the most efficient routes.

- Considering factors such as distance, travel time, and vehicle capacity.

Collaboration and communication:

- Coordinating with drivers and dispatchers to adjust routes as needed.

- Providing real-time updates on delivery schedules and any unexpected delays.

3. Describe your experience in implementing and managing a warehouse management system (WMS).

My experience with WMS implementation and management includes:

- Process mapping and analysis: Documenting and streamlining warehouse operations to identify areas for improvement.

- Vendor selection and integration: Evaluating and choosing WMS software that aligns with business requirements and seamlessly integrates with other systems.

- System configuration and optimization: Customizing the WMS to meet specific business needs and maximizing its functionality.

- User training and support: Providing comprehensive training to warehouse staff on WMS usage and providing ongoing support to ensure efficient adoption.

- Performance monitoring and reporting: Tracking key metrics to evaluate WMS effectiveness and identifying opportunities for further optimization.

4. How do you ensure the accuracy and timeliness of inventory data?

To maintain accurate and timely inventory data, I employ the following practices:

- Cycle counting: Regular physical verification of inventory levels to identify and correct discrepancies.

- Barcode scanning and RFID technology: Automating data entry and reducing errors in inventory tracking.

- Inventory management software: Centralizing inventory data and providing real-time visibility into stock levels.

- Collaboration with suppliers: Establishing clear communication channels to obtain timely updates on deliveries and stock availability.

- Standard operating procedures (SOPs): Implementing clear guidelines for inventory management practices to ensure consistency and accuracy.

5. Describe your approach to forecasting demand for logistics planning.

My approach to demand forecasting for logistics planning involves:

- Historical data analysis: Examining historical sales data, seasonality, and trends to identify patterns and project future demand.

- Market research: Conducting market research to understand industry trends, customer preferences, and competitive activity.

- Statistical modeling: Using statistical models, such as time series analysis or regression, to predict future demand based on historical data and external factors.

- Scenario planning: Developing multiple demand forecasts based on different assumptions to prepare for various business conditions.

- Collaboration with sales and marketing: Gathering insights from sales and marketing teams to align demand forecasts with business objectives.

6. How do you handle and resolve logistics-related exceptions or disruptions?

I approach logistics-related exceptions or disruptions by:

- Rapid response and assessment: Promptly identifying and evaluating the situation to understand its impact and potential consequences.

- Communication and coordination: Engaging with stakeholders, including customers, suppliers, and internal teams, to coordinate a response.

- Contingency planning: Utilizing pre-established contingency plans or developing alternative solutions to mitigate the impact of disruptions.

- Root cause analysis: Investigating the underlying causes of exceptions or disruptions to prevent recurrence.

- Continuous improvement: Implementing measures to enhance processes and systems to reduce the likelihood and severity of future disruptions.

7. Describe your experience in managing third-party logistics (3PL) providers.

My experience in managing 3PL providers includes:

- Vendor evaluation and selection: Assessing potential 3PL providers based on their capabilities, reliability, and alignment with business needs.

- Contract negotiation: Negotiating contracts that clearly define service levels, pricing, and performance expectations.

- Performance monitoring and management: Regularly evaluating 3PL providers against agreed-upon metrics and addressing any underperformance issues.

- Collaboration and communication: Establishing open communication channels to ensure effective coordination and alignment with business objectives.

- Continuous improvement: Working with 3PL providers to identify and implement opportunities for process optimization and cost reduction.

8. How do you stay updated on industry best practices and technological advancements in logistics?

I stay updated on industry best practices and technological advancements in logistics through:

- Attending industry conferences and webinars: Participating in professional events to learn about emerging trends and innovative solutions.

- Reading industry publications and research: Regularly reviewing industry magazines, white papers, and other resources to stay informed about new developments.

- Networking with professionals: Connecting with industry experts, thought leaders, and peers to exchange knowledge and insights.

- Exploring online resources: Utilizing online platforms, such as industry blogs and forums, to access valuable content and engage in discussions.

- Continuous learning: Pursuing further education, certifications, or training programs to enhance my knowledge and skills.

9. How do you contribute to continuous improvement and innovation in logistics operations?

I contribute to continuous improvement and innovation in logistics operations by:

- Process analysis and optimization: Identifying inefficiencies in current processes and developing solutions to improve efficiency and reduce costs.

- Technology adoption: Evaluating and implementing new technologies to automate tasks, enhance visibility, and improve decision-making.

- Benchmarking and best practice sharing: Comparing performance to industry benchmarks and sharing best practices with colleagues to drive innovation.

- Collaboration and idea generation: Encouraging teamwork and fostering an environment where employees are encouraged to contribute ideas for improvement.

- Data analytics: Utilizing data analysis to identify trends, patterns, and areas for optimization in logistics operations.

10. Describe your approach to risk management in logistics operations.

My approach to risk management in logistics operations involves:

- Risk identification and assessment: Identifying potential risks and assessing their likelihood and impact on logistics operations.

- Mitigation strategies: Developing and implementing strategies to minimize or eliminate identified risks, such as contingency plans, supplier diversification, or safety protocols.

- Monitoring and review: Regularly monitoring risks and reviewing mitigation strategies to ensure their effectiveness and make adjustments as needed.

- Communication and training: Communicating risk management plans and training employees on risk identification and prevention measures.

- Continuous improvement: Regularly evaluating and improving risk management practices to enhance resilience and protect logistics operations from potential disruptions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Operations Logistics Analyst.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Operations Logistics Analyst‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Operations Logistics Analyst, you will be responsible for analyzing, designing, and implementing logistics solutions to improve operational efficiency and customer satisfaction. Your primary tasks will include:

1. Supply Chain Management

Analyze and optimize supply chain operations to reduce lead times, minimize costs, and improve inventory management.

- Conduct thorough assessments of supply chain processes and identify areas for improvement.

- Develop and implement supply chain strategies to enhance efficiency and customer satisfaction.

2. Data Analysis and Reporting

Collect, analyze, and interpret data to identify trends, patterns, and opportunities for optimization. Prepare comprehensive reports and present findings to stakeholders.

- Utilize data analysis tools and techniques to extract insights from complex data sets.

- Create compelling visualizations and reports that clearly communicate data-driven recommendations.

3. Process Improvement and Optimization

Identify and implement process improvements to enhance operational efficiency, reduce waste, and improve customer outcomes.

- Use lean principles and Six Sigma methodologies to identify and eliminate bottlenecks and inefficiencies.

- Collaborate with cross-functional teams to streamline processes and improve communication.

4. Project Management

Lead and manage logistics projects from initiation to completion, ensuring timely delivery and successful implementation.

- Develop project plans, budgets, and timelines.

- Monitor project progress and make necessary adjustments to ensure successful outcomes.

Interview Tips

To prepare for your interview as an Operations Logistics Analyst, here are some tips:

1. Research the Company and Industry

Demonstrate your understanding of the company’s logistics operations and the industry landscape. Research the company’s recent initiatives, challenges, and key players.

- Visit the company’s website to learn about their products, services, and logistics strategies.

- Read industry publications and news articles to stay informed about current trends and best practices.

2. Practice Your Technical Skills

Be prepared to discuss your technical skills, such as data analysis, process improvement, and supply chain management.

- Review your resume and highlight your relevant experiences and qualifications.

- Practice answering common technical questions, such as your understanding of inventory optimization techniques or your experience with specific data analysis tools.

3. Emphasize Your Communication and Problem-Solving Abilities

Logistics analysts must be able to effectively communicate their findings and recommendations. Prepare to discuss your communication style and how you would approach problem-solving in a fast-paced environment.

- Provide examples of presentations or reports you have created that clearly communicated complex information.

- Share instances where you have successfully identified and resolved operational challenges.

4. Prepare Questions for the Interviewers

Prepare a few thoughtful questions to ask the interviewers. This shows your engagement and interest in the role and the company.

- Ask about the company’s future plans for logistics operations and technology.

- Inquire about the specific challenges and opportunities facing the logistics team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Operations Logistics Analyst interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.