Are you gearing up for a career in Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

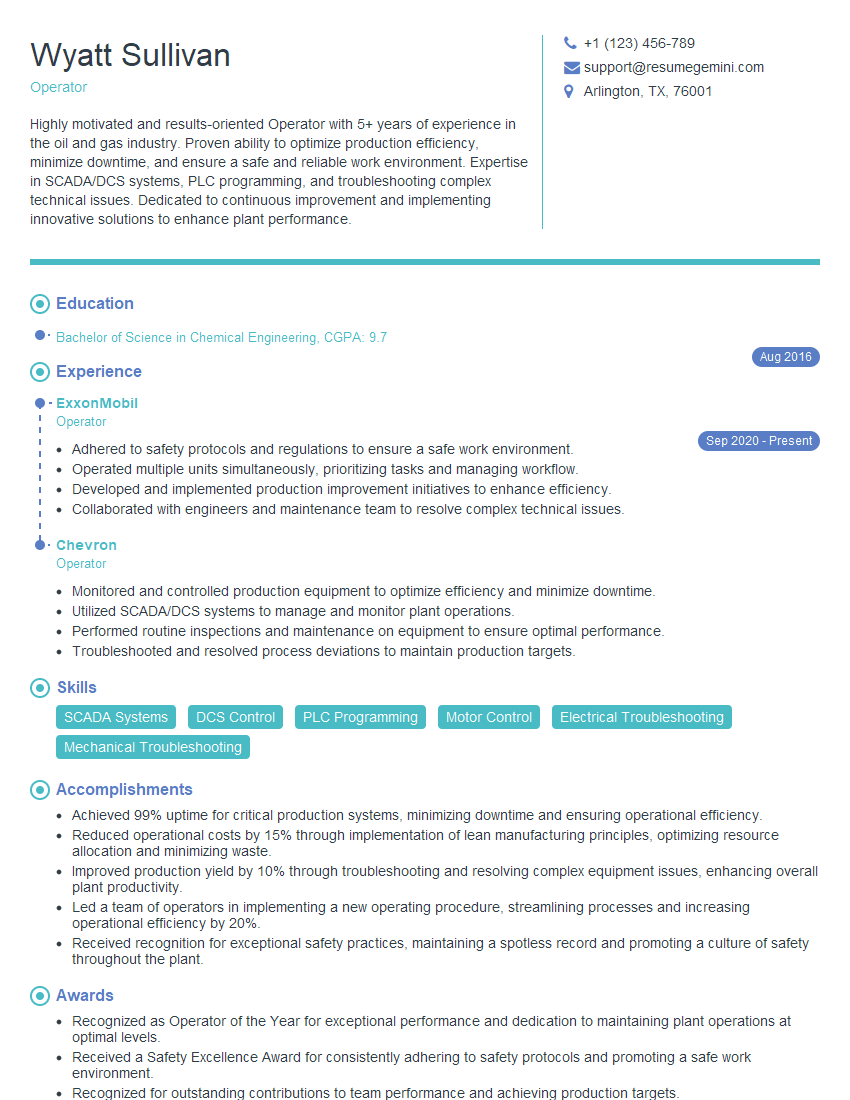

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Operator

1. What are the key responsibilities of an Operator?

As an Operator, my key responsibilities are to ensure the smooth and efficient operation of production processes, monitor equipment, and make necessary adjustments to maintain optimal performance. I am also responsible for troubleshooting and resolving technical issues, adhering to safety protocols, and implementing quality control measures.

2. Describe your experience in operating and maintaining production equipment.

Equipment Operation

- Proficient in operating a wide range of production machinery, including automated lines, CNC machines, and assembly equipment.

- Skilled in calibrating and adjusting equipment to achieve precise operating parameters and ensure optimal output.

Maintenance and Repair

- Conduct regular preventive maintenance tasks to minimize downtime and extend equipment lifespan.

- Troubleshoot and diagnose equipment malfunctions, perform repairs, and replace faulty components.

3. How do you monitor and optimize production processes?

I monitor production processes using real-time dashboards, control panels, and process data. By observing trends and identifying deviations from target values, I can make timely adjustments to process parameters, such as temperature, pressure, and feed rate, to maintain efficiency and quality. I also use statistical process control techniques to identify areas for improvement and implement optimization strategies.

4. What steps do you take to ensure product quality?

I implement a comprehensive quality control program that includes:

- Regular inspection and testing of products at various stages of production.

- Adhering to established quality standards and protocols.

- Monitoring customer feedback and analyzing data to identify areas for improvement.

- Collaborating with quality assurance personnel to ensure compliance with regulations and industry best practices.

5. How do you handle production emergencies and unexpected events?

In the event of a production emergency or unexpected event, I take the following steps:

- Assess the situation and identify the root cause of the issue.

- Implement immediate corrective actions to minimize downtime and production loss.

- Communicate the situation to supervisors and other relevant personnel.

- Document the incident and the actions taken to resolve it.

- Conduct a thorough investigation to identify systemic issues and implement preventive measures.

6. What is your experience in using data analysis and reporting tools?

I have experience in using data analysis and reporting tools, such as Microsoft Excel, Power BI, and Tableau, to:

- Monitor production trends and identify areas for improvement.

- Generate reports on production efficiency, downtime, and quality metrics.

- Analyze data to identify root causes of problems and develop solutions.

- Create visualizations to communicate insights and recommendations to stakeholders.

7. How do you stay up-to-date with advancements in manufacturing processes and technologies?

I stay up-to-date with advancements in manufacturing processes and technologies by:

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and discussions.

- Collaborating with experts and thought leaders in the field.

8. What are the safety protocols that you follow in the workplace?

I am committed to maintaining a safe work environment and strictly adhere to all established safety protocols, including:

- Wearing appropriate personal protective equipment (PPE).

- Following lockout/tagout procedures.

- Using equipment properly and as intended.

- Reporting any hazards or unsafe conditions immediately.

- Participating in safety training and drills.

9. How do you prioritize and manage multiple tasks while ensuring quality and efficiency?

I prioritize and manage multiple tasks by:

- Using a task management system to keep track of assignments and deadlines.

- Breaking down complex tasks into smaller, manageable steps.

- Delegating tasks to others when appropriate.

- Focusing on completing urgent and important tasks first.

- Monitoring progress and making adjustments as needed to ensure timelines and quality standards are met.

10. What is your understanding of the principles of lean manufacturing?

Lean manufacturing is a production philosophy that focuses on eliminating waste and improving efficiency. I understand the key principles of lean manufacturing, including:

- Identifying and eliminating waste in all forms.

- Creating a continuous flow of value-added activities.

- Empowering employees to improve processes and solve problems.

- Using data to drive decision-making and continuous improvement.

- Building a culture of respect and teamwork.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Operators play a crucial role in various industries, including manufacturing, transportation, and customer service. Their responsibilities encompass a wide range of tasks essential for the smooth and efficient functioning of organizations.

1. Monitoring and Controlling Equipment

- Operate and monitor equipment such as machinery, vehicles, or computer systems.

- Ensure that equipment is functioning properly and make necessary adjustments to maintain optimal performance.

2. Maintaining Equipment

Conduct routine maintenance and repairs on equipment to prevent breakdowns and ensure longevity.

- Clean, inspect, and lubricate equipment as per established schedules.

- Identify and resolve minor issues promptly to prevent escalation into major problems.

3. Quality Control

Monitor and ensure the quality of products or services produced by the equipment they operate.

- Inspect products for defects and adherence to specifications.

- Implement quality control measures and report any deviations to supervisors.

4. Communication and Coordination

Communicate effectively with supervisors, colleagues, and customers as required.

- Provide status updates and report any issues or concerns.

- Coordinate with other departments to ensure smooth workflow and resolve problems.

Interview Tips

Preparing for an Operator interview requires careful planning and execution. By following these tips, you can increase your chances of making a positive impression and securing the job.

1. Research the Company and Role

- Visit the company website to gather information about its industry, products or services, and culture.

- Thoroughly review the job description to understand the specific responsibilities and requirements of the role.

2. Practice Your Answers

Prepare for common interview questions related to your skills, experience, and knowledge of the industry.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

- Consider practicing with a friend or family member for constructive feedback.

3. Highlight Relevant Skills and Experience

Emphasize your technical skills, such as equipment operation, maintenance, and quality control.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- If you have experience in a similar industry or role, highlight the transferable skills that are relevant to the position.

4. Demonstrate Your Commitment

Express your enthusiasm for the role and the industry. Explain how your values and career aspirations align with the company’s goals.

- Share examples of your dedication to quality and efficiency.

- Demonstrate your willingness to learn and grow within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!