Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Optical Coating Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Optical Coating Technician so you can tailor your answers to impress potential employers.

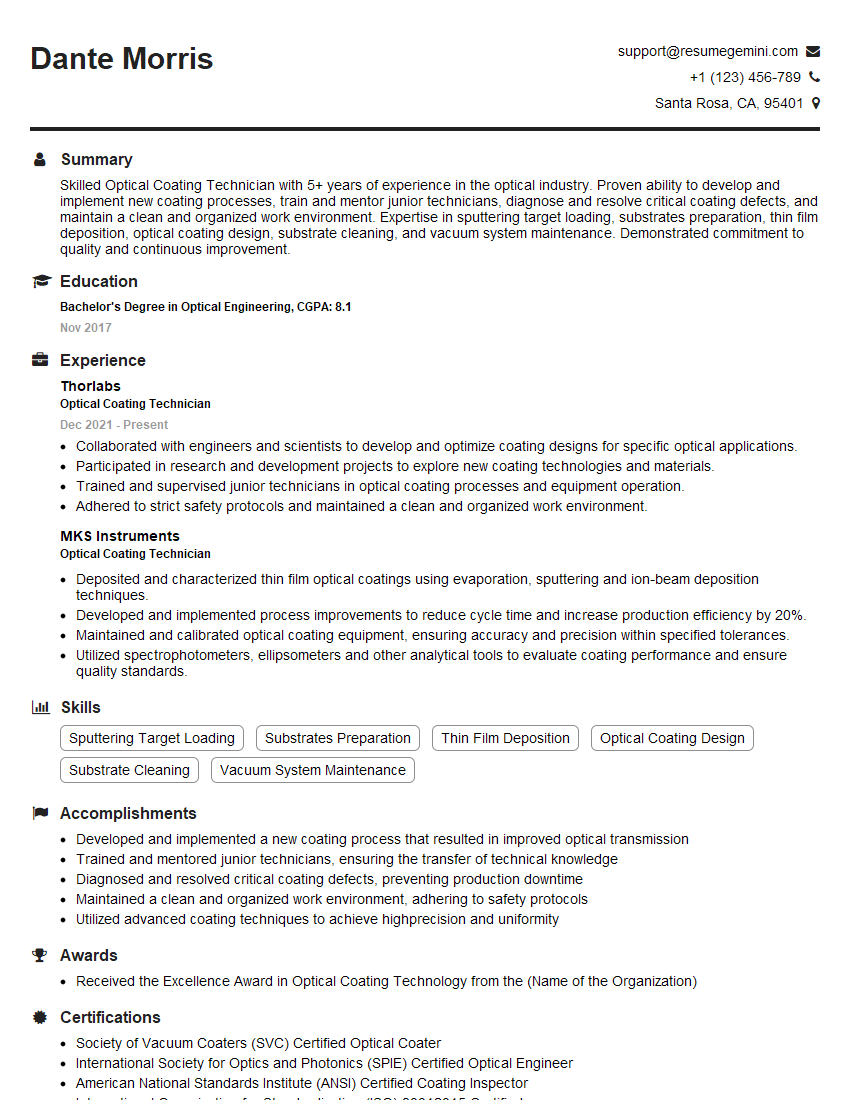

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Optical Coating Technician

1. Describe the vacuum deposition process for optical coating.

- Begin by cleaning the substrate to remove contaminants.

- Place the substrate in a vacuum chamber and evacuate the chamber to remove air.

- Introduce the coating material into the chamber and vaporize it using a variety of techniques such as evaporation, sputtering, or chemical vapor deposition (CVD).

- The vaporized coating material condenses on the substrate, forming a thin film.

- Control the thickness and properties of the coating by varying the deposition parameters such as temperature, pressure, and deposition rate.

2. What are the different types of optical coatings and their applications?

Anti-reflection coatings

- Reduce or eliminate reflections from optical surfaces, increasing light transmission.

- Used in lenses, prisms, and other optical components.

Reflective coatings

- Enhance the reflectivity of optical surfaces.

- Used in mirrors, laser cavities, and other applications requiring high reflectivity.

Bandpass filters

- Transmit light within a specific wavelength range while blocking light outside that range.

- Used in spectroscopy, imaging, and other applications requiring wavelength selectivity.

Dichroic coatings

- Reflect or transmit light differently depending on the wavelength.

- Used in beamsplitters, color filters, and other applications requiring wavelength-dependent behavior.

3. Explain the principles of thin-film interference and how they are used in optical coatings.

- Thin-film interference occurs when light waves reflect from multiple surfaces of a thin film.

- The interference can be constructive or destructive, resulting in either increased or decreased light transmission or reflection.

- By carefully controlling the thickness and refractive index of the thin film, it is possible to design optical coatings with specific optical properties.

4. Describe the equipment and techniques used for optical coating deposition.

- Vacuum deposition chamber: A sealed chamber where the coating process takes place.

- Evaporation sources: Devices that vaporize the coating material, such as thermal evaporators or electron beam guns.

- Sputtering targets: Targets that are bombarded with ions to release the coating material.

- Optical monitoring systems: Devices that measure the optical properties of the coating during deposition.

- Substrate holders: Devices that hold the substrates during deposition.

5. What are the key factors that affect the quality of optical coatings?

- Substrate cleanliness: Contaminants on the substrate can affect the adhesion and optical properties of the coating.

- Deposition conditions: Temperature, pressure, and deposition rate can influence the coating’s structure, thickness, and optical properties.

- Material properties: The refractive index, absorption coefficient, and other properties of the coating material affect the optical performance of the coating.

- Environmental factors: Exposure to moisture, temperature variations, and other environmental factors can degrade the coating’s performance over time.

6. Describe the methods used to characterize optical coatings.

- Spectrophotometry: Measures the transmission, reflection, or absorption of light over a range of wavelengths.

- Ellipsometry: Determines the thickness and refractive index of thin films.

- Atomic force microscopy (AFM): Images the surface of the coating to assess its morphology and roughness.

- Scanning electron microscopy (SEM): Provides high-resolution images of the coating’s surface and cross-section.

7. Explain the role of optical coating in laser systems.

- Anti-reflection coatings: Reduce reflections from laser optics, improving laser efficiency and reducing unwanted feedback.

- Reflective coatings: Enhance the reflectivity of laser mirrors, increasing laser power and beam quality.

- Bandpass filters: Isolate specific laser wavelengths, allowing for wavelength selection and filtering.

- Dichroic coatings: Separate different laser wavelengths, enabling multiple laser beams to be combined or separated.

8. Describe the challenges and trends in optical coating technology.

Challenges

- Producing high-quality coatings on complex or large substrates.

- Meeting the increasing demands for high precision and low loss coatings.

- Developing coatings that are resistant to environmental degradation.

Trends

- Use of advanced deposition techniques to achieve precise control over coating properties.

- Development of new coating materials with improved performance.

- Integration of optical coatings into micro- and nanotechnologies.

9. What are the safety precautions that need to be taken when working with optical coating equipment and materials?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and lab coats.

- Handle hazardous materials, such as chemicals and solvents, with care.

- Be aware of the potential for electrical hazards and take appropriate precautions.

- Follow all safety protocols and procedures established by the workplace.

10. Describe your experience with optical coating techniques and equipment.

Experience with deposition techniques:

- Thermal evaporation

- Electron beam evaporation

- Sputtering

- Chemical vapor deposition (CVD)

Experience with equipment:

- Vacuum deposition systems

- Optical monitoring systems

- Substrate holders

- Characterization equipment (spectrophotometer, ellipsometer, AFM, SEM)

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Optical Coating Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Optical Coating Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Optical Coating Technician, your primary role will be to apply optical coatings to optical components, ensuring that they meet the required specifications. This highly specialized position demands expertise in coating techniques, quality control procedures, and a commitment to delivering high-quality products.

1. Coating Application and Process

You will be entrusted with the responsibility of preparing optical components for coating, selecting and applying appropriate coating materials, and precisely controlling coating parameters to achieve desired optical properties.

- Prepare optical components for coating, ensuring proper surface cleanliness and adherence.

- Select and apply optical coating materials using various techniques, including vacuum deposition, sputtering, and evaporation.

- Control coating parameters such as thickness, refractive index, and surface roughness to meet precise specifications.

- Monitor and maintain coating equipment to ensure optimal performance and consistent results.

2. Quality Control and Inspection

Your responsibilities extend beyond coating application to ensuring the quality of the final product. You will perform rigorous inspections and testing to verify compliance with specifications and identify any potential defects.

- Conduct optical inspections using microscopes, spectrophotometers, and other specialized equipment.

- Measure coating thickness, refractive index, and other optical properties to ensure conformance with specifications.

- Identify and resolve coating defects, such as scratches, pinholes, and contamination.

- Maintain detailed records of coating processes and quality control results for traceability and documentation.

3. Research and Development

In this role, you may also contribute to research and development efforts, exploring new coating technologies and materials to enhance product performance. Your expertise will be instrumental in developing innovative solutions for the optical industry.

- Participate in research projects to develop new coating materials and processes.

- Evaluate the performance of new coatings and make recommendations for improvements.

- Stay abreast of industry advancements and emerging technologies to maintain technical proficiency.

4. Teamwork and Communication

Collaboration is crucial in this role. You will work closely with engineers, scientists, and other technicians to ensure that coating processes align with overall project objectives. Effective communication and documentation are key to maintaining clear and concise project progress.

- Collaborate with design engineers to understand coating requirements and specifications.

- Communicate coating process parameters, quality control results, and any potential issues to stakeholders.

- Maintain a clean and organized work environment, adhering to safety regulations and best practices.

Interview Tips

Preparing for your interview as an Optical Coating Technician is essential to showcase your skills and qualifications. Here are some tips to help you ace the interview:

1. Research the Company and Role

Thoroughly research the company you’re applying to, their products, and the specific role you’re interviewing for. This will enable you to speak intelligently about the company’s mission and how your skills align with their needs.

- Visit the company’s website and social media pages.

- Review the job description and identify keywords that highlight the required skills and experience.

2. Prepare Your Elevator Pitch

Prepare a concise and engaging elevator pitch that outlines your relevant skills, experience, and qualifications. This brief introduction should captivate the interviewer and make them eager to learn more about you.

- Highlight your expertise in optical coating techniques, quality control procedures, and relevant industry knowledge.

- Quantify your achievements whenever possible, using specific metrics and examples.

3. Practice Answering Common Interview Questions

Familiarize yourself with common interview questions and prepare thoughtful answers that demonstrate your competence. Research industry-specific questions and technical concepts that may be relevant to the role.

- Expected Interview Questions for Optical Coating Technicians:

- – Describe your experience in applying optical coatings using various techniques.

- – Explain the quality control procedures you follow to ensure coating quality.

- – Tell us about a challenging coating project you successfully completed.

4. Anticipate Technical Questions

Be prepared for technical questions that assess your understanding of optical coating principles and equipment. Review the basics of optics, coating materials, and measurement techniques.

- – Expected Technical Questions for Optical Coating Technicians:

- – What are the different types of optical coatings and their applications?

- – Describe the process of thin-film deposition and how it is used in optical coating.

- – Explain the factors that affect the optical properties of coatings.

5. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest and engagement. This is an opportunity to gain insights into the company’s culture, growth opportunities, and the specific challenges you may face in the role.

- – Example Questions to Ask the Interviewer:

- – What are the current challenges and opportunities in the optical coating industry?

- – What are the company’s plans for future growth and innovation in optical coating?

- – What opportunities are there for professional development and advancement in this role?

6. Dress Professionally and Be Yourself

First impressions matter, so dress professionally and arrive on time for your interview. Maintain eye contact, speak clearly and confidently, and be yourself. Let your passion for optical coating and your desire to contribute to the company’s success shine through.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Optical Coating Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Optical Coating Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.