Are you gearing up for an interview for a Optical Goods Drill Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Optical Goods Drill Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

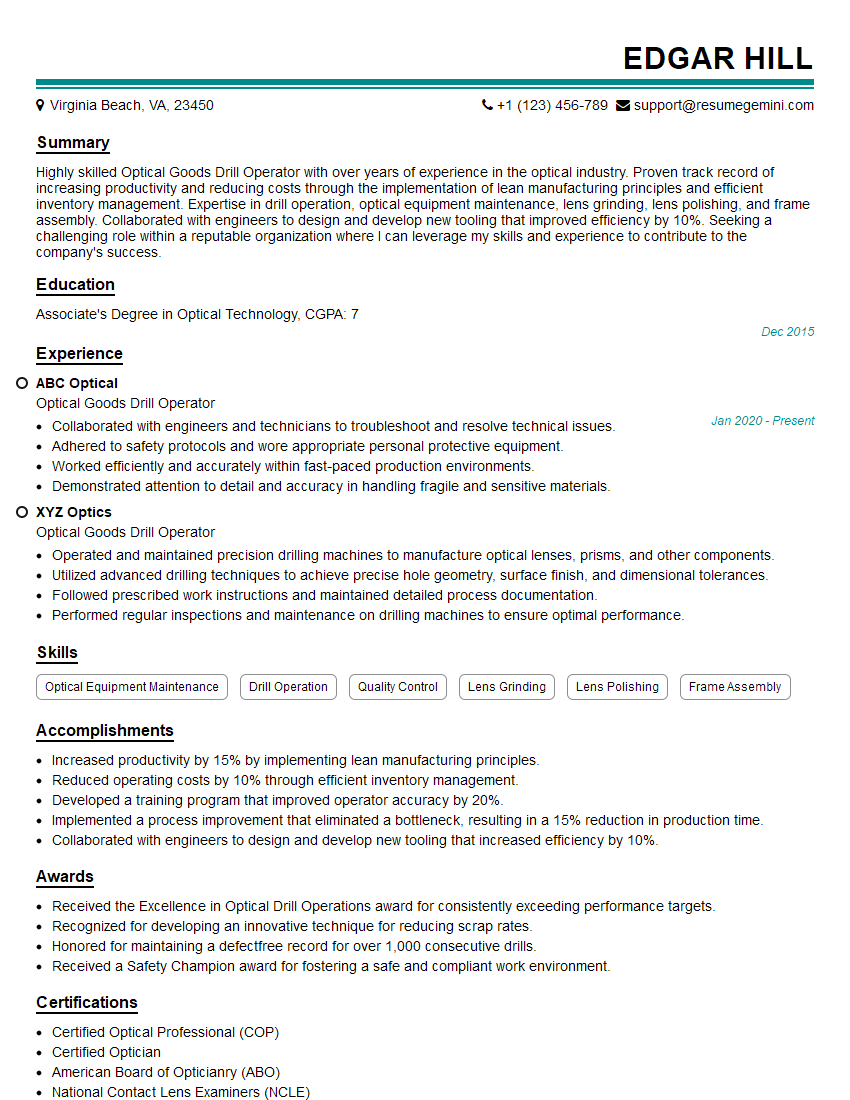

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Optical Goods Drill Operator

1. What is the purpose of using a jig and fixture in optical goods drilling?

- A jig is a device that holds and guides a workpiece during drilling, ensuring precision and repeatability.

- A fixture, on the other hand, is used to secure the workpiece and provide support during drilling operations, preventing movement or vibration.

2. What are the different types of drill bits used in optical goods drilling?

- Carbide-tipped drill bits: These are highly durable and can drill through hard materials like glass and ceramics.

- Diamond-tipped drill bits: These are used for drilling extremely hard materials like gemstones.

- Fluted drill bits: These are designed to remove chips and debris from the drilling process efficiently.

- Step drill bits: These bits drill holes in various diameters with a single tool, eliminating the need for multiple drill bits.

3. How do you determine the correct feed rate and spindle speed for optical goods drilling?

- The appropriate feed rate depends on the material being drilled, the diameter of the drill bit, and the desired hole quality.

- The spindle speed should be adjusted based on the material’s hardness and the drill bit size to prevent excessive wear or breakage.

4. What are the key safety precautions to observe when operating an optical goods drilling machine?

- Wear appropriate eye protection, such as safety glasses or goggles.

- Ensure the workpiece is securely held to prevent movement during drilling.

- Keep hands away from rotating parts and use a safety guard when possible.

- Use sharp drill bits to avoid excessive force and potential breakages.

- Regularly inspect equipment and ensure it is in good working order.

5. How do you maintain an optical goods drilling machine to ensure its accuracy and precision?

- Regularly clean and lubricate the machine to prevent wear and tear.

- Check the drill bits for sharpness and replace them when necessary.

- Inspect the jig and fixture for damage and ensure they are in good condition.

- Calibrate the machine periodically using a reference workpiece to maintain accuracy.

6. What is the difference between dry drilling and wet drilling in optical goods drilling?

- Dry drilling: No coolant is used during the drilling process, which can generate heat and dust.

- Wet drilling: A coolant or lubricant is applied during drilling to reduce heat, improve chip removal, and extend tool life.

7. How do you measure and ensure the accuracy of drilled holes in optical goods?

- Use precision measuring tools such as calipers, micrometers, or coordinate measuring machines (CMMs) to measure hole dimensions.

- Compare the measured values to the specified tolerances to ensure accuracy.

8. What are the common defects that can occur during optical goods drilling and how do you prevent them?

- Chipping: Use sharp drill bits and apply light pressure to prevent chipping.

- Cracking: Ensure the workpiece is securely held and use a jig or fixture to minimize vibrations.

- Burring: Use a deburring tool or abrasive stone to remove any sharp edges.

- Oversized holes: Use the correct drill bit size and adjust the feed rate to prevent excessive material removal.

9. How do you troubleshoot common problems encountered while operating an optical goods drilling machine?

- Drill bit breakage: Check for blunt or damaged drill bits, adjust the feed rate, or ensure the workpiece is securely held.

- Poor hole quality: Inspect the drill bit for wear or damage, clean the workpiece and drill bit, or adjust the spindle speed and feed rate.

- Machine vibration: Check for loose components, unbalanced drill bits, or insufficient workpiece clamping.

10. What is your understanding of the latest advancements in optical goods drilling technology?

- Laser drilling: Uses a focused laser beam to create precise holes without the need for mechanical drilling.

- Ultrasonic drilling: Utilizes high-frequency sound waves to drill delicate or fragile materials.

- Computer numerical control (CNC) drilling: Allows for automated and precise drilling operations controlled by a computer program.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Optical Goods Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Optical Goods Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Optical Goods Drill Operator is responsible for the precision drilling of optical goods such as lenses, frames, and mountings. They ensure that the drilled holes meet the required specifications and tolerances, and that the finished products are of high quality.

1. Drilling Operations

Operate drilling machines to create precise holes in optical components, such as lenses, frames, and mountings.

- Set up and calibrate drilling machines according to job specifications.

- Select and install appropriate drill bits and cutting tools.

- Position and secure optical components to ensure accurate drilling.

- Monitor drilling process to ensure adherence to quality standards.

- Inspect drilled holes to verify conformance to specifications.

2. Quality Control

Inspect and measure drilled holes to ensure they meet the required specifications and tolerances.

- Use precision measuring tools, such as calipers and micrometers, to measure hole dimensions.

- Identify and correct any deviations from specifications.

- Maintain records of inspection and measurement results.

3. Equipment Maintenance

Perform routine maintenance and calibration of drilling machines and other equipment.

- Lubricate, clean, and adjust drilling machines to ensure optimal performance.

- Troubleshoot and resolve equipment malfunctions.

- Follow established safety protocols to prevent accidents and injuries.

4. Production Support

Assist in other production tasks, such as material handling and inventory control.

- Move and store optical components and materials.

- Maintain inventory records and ensure availability of materials.

- Follow production schedules and meet deadlines.

Interview Tips

To ace your interview for an Optical Goods Drill Operator position, it’s crucial to prepare thoroughly and present yourself effectively. Here are some tips to help you succeed:

1. Research the Company and Position

Take the time to research the company and the specific role you’re applying for. This will give you a better understanding of the company’s culture, values, and expectations for the position. It will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about their history, products, and services.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

- Practice answering common interview questions related to the optical industry.

2. Highlight Your Skills and Experience

During the interview, emphasize your relevant skills and experience that make you a qualified candidate for the position. Be specific and provide concrete examples to demonstrate your abilities.

- Quantify your accomplishments whenever possible. For instance, instead of saying “I worked on a team that improved production efficiency,” say “I contributed to a team effort that increased production efficiency by 15% through the implementation of new drilling techniques.”

- Use the STAR method to answer behavioral interview questions. STAR stands for Situation, Task, Action, Result. When describing your experience, provide the context (Situation), your responsibilities (Task), the actions you took (Action), and the outcomes (Result).

3. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the position. It also gives you an opportunity to clarify any questions you have about the company or the role.

- Ask about the company’s growth plans and how the position fits into those plans.

- Inquire about opportunities for professional development and training.

- Ask about the company’s commitment to quality and customer satisfaction.

4. Follow Up

After the interview, send a thank-you note to the interviewer. This is a simple but effective way to express your appreciation for their time and consideration.

- Reiterate your interest in the position and highlight your key qualifications.

- Thank the interviewer for their time and express your enthusiasm for the opportunity.

- Restate your availability for future communication and indicate your willingness to provide additional information if needed.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Optical Goods Drill Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.