Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Optical Instrument Repairer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

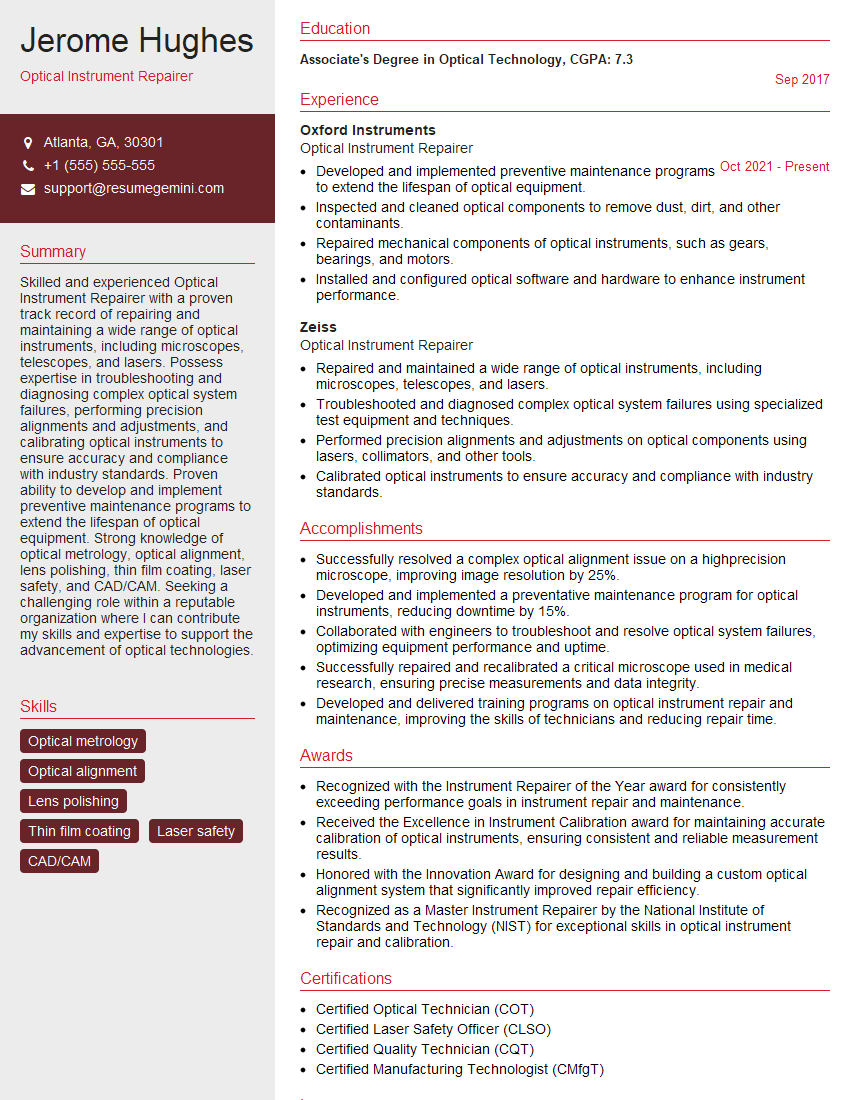

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Optical Instrument Repairer

1. Describe the process of aligning and adjusting an optical microscope.

The alignment and adjustment of an optical microscope is a crucial step to ensure optimal image quality and accurate measurements. Here’s the process:

- Coarse Alignment: Use the coarse focus knob to bring the specimen into approximate focus.

- Fine Alignment: Adjust the fine focus knob to sharpen the image.

- Köhler Illumination: Adjust the condenser height and diaphragm to achieve even illumination of the specimen.

- Condenser Alignment: Center the condenser and adjust its height to optimize contrast.

- Eyepiece Alignment: Adjust the interpupillary distance and diopter settings to ensure clear and comfortable viewing.

2. How do you troubleshoot and repair a broken optical instrument?

Troubleshooting and repairing optical instruments involves a systematic approach:

- Identify the Issue: Perform visual inspection and gather information from the user to determine the nature of the problem.

- Diagnose the Cause: Examine potential causes based on knowledge of the instrument’s components and functionality.

- Resolve the Problem: Repair or replace faulty components, adjust alignments, or clean optical surfaces as necessary.

- Test and Verify: After the repair, thoroughly test the instrument to ensure it meets specifications and performs as expected.

3. What are the safety precautions to consider when working with high-powered lasers?

Working with high-powered lasers requires strict safety precautions to prevent injury:

- Wear Laser Safety Glasses: Always wear appropriate laser safety glasses to protect eyes from harmful radiation.

- Use Shielding: Use laser enclosures or beam blocks to contain the laser beam and prevent exposure.

- Avoid Direct Eye Exposure: Never look directly into the laser beam or its reflections.

- Secure the Setup: Ensure the laser setup is stable and secure to prevent accidental movement.

- Follow Laser Safety Guidelines: Adhere to established laser safety guidelines and protocols for specific laser systems.

4. How do you calibrate an optical interferometer?

Calibration of an optical interferometer ensures accurate measurements:

- Reference Mirror Alignment: Align the reference mirror perpendicular to the laser beam path.

- Wavelength Calibration: Use a reference light source to calibrate the interferometer to a known wavelength.

- Path Length Compensation: Adjust the optical path length to compensate for environmental factors (e.g., temperature, pressure).

- Fringe Pattern Analysis: Observe interference fringes and adjust the optical setup to achieve maximum fringe visibility and stability.

- Environmental Control: Monitor and control environmental conditions (e.g., temperature, vibration) to minimize measurement errors.

5. What are the different types of optical coatings and their applications?

Optical coatings enhance the performance of optical components:

- Anti-Reflection Coatings: Reduce light reflection, improving transmission and reducing ghosting.

- High-Reflection Coatings: Increase light reflection, used in mirrors and beamsplitters.

- Bandpass Filters: Transmit light within a specific wavelength range, used in spectroscopy.

- Dichroic Coatings: Separate light based on wavelength, used in color filters and beamsplitters.

- Polarizing Filters: Control the polarization of light, used in imaging and analysis.

6. Explain the principle of optical fiber transmission.

Optical fiber transmission utilizes the phenomenon of total internal reflection:

- Total Internal Reflection: Light stays confined within the fiber core due to repeated reflections at the core-cladding interface.

- Low Attenuation: High-quality fibers minimize light loss over long distances.

- Information Encoding: Light intensity, phase, or polarization can be modulated to transmit information.

- Signal Regeneration: Repeaters or amplifiers boost the signal at regular intervals to compensate for attenuation.

7. How do you troubleshoot a malfunctioning spectrometer?

Spectrometer troubleshooting involves identifying the source of the problem:

- Light Source Check: Verify if the light source is operating correctly.

- Optical Alignment: Ensure that all optical components are aligned properly.

- Wavelength Calibration: Calibrate the spectrometer to the desired wavelength range.

- Detector Sensitivity: Check the sensitivity and linearity of the detector.

- Software Interface: Inspect the software for errors or compatibility issues.

8. What is the difference between a collimator and a beam expander?

- Collimator: Converts a diverging light beam into a collimated (parallel) beam, used in laser systems and optical instruments.

- Beam Expander: Increases the beam diameter of a laser beam, used to reduce beam divergence and increase focusing power.

9. How do you align a laser diode?

- Coarse Alignment: Use a laser pointer to get the laser beam close to the desired path.

- Fine Alignment: Adjust the laser diode’s position and orientation using micrometer screws or actuators.

- Beam Profiling: Use a beam profiler to visualize the laser beam and optimize its shape and alignment.

10. What are the advantages of using an optical fiber laser over a traditional solid-state laser?

- Compact Size and Flexibility: Optical fiber lasers are smaller and more flexible than solid-state lasers.

- High Beam Quality: They produce beams with excellent beam quality and low divergence.

- Wavelength Versatility: Optical fiber lasers can be tailored to emit at various wavelengths.

- High Power and Efficiency: They can deliver high power output with good energy efficiency.

- Cost-Effective: They offer competitive pricing compared to traditional solid-state lasers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Optical Instrument Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Optical Instrument Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Optical Instrument Repairers are highly skilled technicians who are responsible for repairing, calibrating, and maintaining a wide range of optical instruments. This includes microscopes, telescopes, lasers, and other specialized equipment. They work in a variety of settings, including laboratories, research institutions, and manufacturing facilities.

1. Troubleshooting and Repairing Optical Instruments

Optical Instrument Repairers are responsible for troubleshooting and repairing a wide range of optical instruments. This includes diagnosing the problem, replacing faulty parts, and calibrating the instrument to ensure it is functioning properly.

- Diagnose problems with optical instruments

- Replace faulty parts

- Calibrate optical instruments

2. Maintaining Optical Instruments

Optical Instrument Repairers are also responsible for maintaining optical instruments. This includes cleaning, lubricating, and adjusting the instrument to ensure it is operating at its best.

- Clean optical instruments

- Lubricate optical instruments

- Adjust optical instruments

3. Calibrating Optical Instruments

Optical Instrument Repairers are responsible for calibrating optical instruments. This involves using specialized equipment to ensure that the instrument is measuring or performing to the required specifications.

- Calibrate optical instruments using specialized equipment

- Ensure that the instrument is measuring or performing to the required specifications

4. Working with Customers

Optical Instrument Repairers often work with customers to troubleshoot problems and provide technical support. They may also provide training on how to use and maintain optical instruments.

- Work with customers to troubleshoot problems

- Provide technical support to customers

- Provide training on how to use and maintain optical instruments

Interview Tips

Preparing for an interview for an Optical Instrument Repairer position can be intimidating, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before you go on an interview, it’s important to research the company and the position you’re applying for. You should learn as much as you can about the company’s history, products, and services. You should also research the specific position you’re applying for and the qualifications required.

- Visit the company’s website

- Read articles about the company in the news

- Talk to people who work at the company

- Review the job description carefully

- Identify the skills and qualifications that are most important for the position

2. Practice Answering Interview Questions

Once you’ve researched the company and the position, you should practice answering interview questions. You should prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”. You should also practice answering questions specific to the position you’re applying for, such as “What experience do you have repairing optical instruments?”.

- Practice answering common interview questions

- Practice answering questions specific to the position you’re applying for

- Use the STAR method to answer interview questions

3. Prepare Questions to Ask the Interviewer

At the end of the interview, you will likely be given an opportunity to ask the interviewer questions. This is a great opportunity to learn more about the company and the position, and to show the interviewer that you’re interested in the job. You should prepare a few questions to ask the interviewer, such as “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”.

- Prepare a few questions to ask the interviewer

- Ask questions that are relevant to the company and the position

- Show the interviewer that you’re interested in the job

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time for your interview. Arriving late will show the interviewer that you’re not serious about the job.

- Dress professionally for your interview

- Arrive on time for your interview

- Make a good first impression

5. Be Enthusiastic and Positive

It’s important to be enthusiastic and positive during your interview. This will show the interviewer that you’re interested in the job and that you’re a team player. You should also be prepared to talk about your skills and experience, and how you can contribute to the company.

- Be enthusiastic and positive during your interview

- Show the interviewer that you’re interested in the job

- Talk about your skills and experience

- Explain how you can contribute to the company

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Optical Instrument Repairer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.