Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Optical Lathe Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

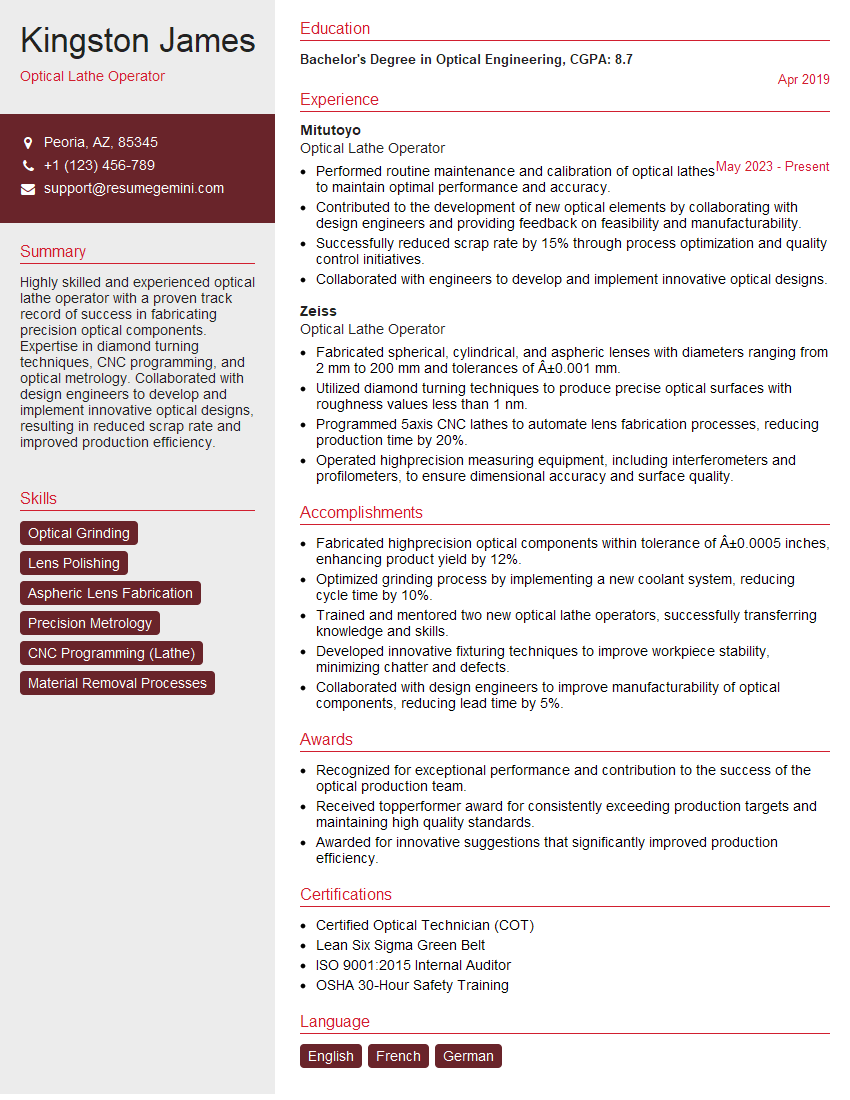

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Optical Lathe Operator

1. Describe the steps involved in setting up an optical lathe?

To set up an optical lathe, the following steps should be taken:

- Mount the workpiece: Secure the workpiece to the lathe’s chuck or collet.

- Align the optical axis: Adjust the lathe’s spindle and tailstock to ensure the optical axis is parallel to the workpiece’s axis of rotation.

- Install the cutting tool: Choose the appropriate cutting tool for the desired operation and mount it on the lathe’s tool post.

- Set the speed and feed rates: Determine the optimal cutting speed and feed rate based on the workpiece material and the desired surface finish.

- Lubricate the cutting zone: Apply a suitable lubricant to the cutting zone to reduce friction and improve surface finish.

2. What are the different types of cutting tools used in optical lathing?

Brazed diamond tools

- Used for precise and fine finishing operations.

- Consist of diamond particles bonded to a metal substrate.

PCD (Polycrystalline Diamond) tools

- Similar to brazed diamond tools but with a higher concentration of diamond particles.

- Offer high wear resistance and extended tool life.

CBN (Cubic Boron Nitride) tools

- Used for machining hard materials such as ceramics and hardened steels.

- Provide excellent surface finish and long tool life.

3. How do you ensure the accuracy of optical lathe operations?

To ensure the accuracy of optical lathe operations:

- Precise alignment: Calibrate and align the lathe’s components regularly to maintain precision.

- Temperature control: Monitor and control the temperature of the workpiece and the machine to prevent thermal expansion and distortion.

- Vibration isolation: Use vibration dampening mounts to minimize the impact of external vibrations on the lathe’s operation.

- Regular calibration: Perform regular calibration of the lathe’s spindle, axis movements, and measuring instruments.

- Skilled operator: Ensure that the operator is well-trained and experienced in precision optical lathing techniques.

4. What are the common defects that can occur in optical lathe operations and how can they be prevented?

Chatter

- Caused by excessive vibration during cutting.

- Preventable by using sharp cutting tools, proper tool geometry, and vibration damping techniques.

Surface roughness

- Caused by improper tool selection or cutting parameters.

- Preventable by using the correct cutting tool, ensuring proper tool alignment, and optimizing cutting speed and feed.

Thermal distortion

- Caused by excessive heat generation during cutting.

- Preventable by using proper lubrication, controlling cutting speed and feed, and maintaining a stable temperature environment.

5. Explain how you troubleshoot common problems that may arise during optical lathe operations.

To troubleshoot common problems during optical lathe operations:

- Identify the problem: Observe the symptoms, such as unusual noises, vibrations, or surface defects.

- Check the basics: Ensure proper workpiece mounting, tool alignment, and cutting parameters.

- Inspect the cutting tool: Check for sharpness, damage, or wear that may affect performance.

- Review the cutting parameters: Adjust cutting speed, feed, and depth of cut as necessary to optimize the operation.

- Examine the workpiece: Check for any defects or imperfections that may hinder the lathing process.

6. Describe the safety precautions you observe when operating an optical lathe.

- Wear appropriate PPE: Safety glasses, gloves, and hearing protection.

- Secure loose clothing: Avoid loose clothing or jewelry that could get caught in the machine.

- Maintain a clean work area: Clear away debris and ensure good lighting.

- Follow proper operating procedures: Adhere to established safety protocols and guidelines.

- Use sharp cutting tools: Dull tools can increase the risk of accidents.

7. How do you measure and inspect the dimensions and surface finish of optical components produced on an optical lathe?

Dimensional measurement:

- Coordinate Measuring Machine (CMM): Used for precise measurement of complex shapes and dimensions.

- Optical Comparator: Compares the workpiece to a known standard using optical techniques.

Surface finish inspection:

- Interferometer: Measures surface roughness and defects using interference patterns.

- Profilometer: Scans the surface to create a profile and quantify surface finish parameters.

8. What is the role of coolant in optical lathe operations?

- Cooling: Removes heat generated during cutting, preventing thermal distortion and prolonging tool life.

- Lubrication: Reduces friction between the cutting tool and workpiece, improving surface finish and reducing tool wear.

- Chip removal: Flushes away cutting chips, maintaining a clear cutting zone and preventing tool clogging.

9. How do you maintain and calibrate an optical lathe?

To maintain and calibrate an optical lathe:

- Regular cleaning: Remove debris, chips, and coolant residue to ensure proper operation.

- Spindle alignment: Check and adjust the spindle’s alignment to maintain precision.

- Axis calibration: Calibrate the X, Y, and Z axes to ensure accurate positioning and movement.

- Toolholder calibration: Ensure the toolholder is properly aligned and calibrated for precise tool positioning.

- Coolant system maintenance: Monitor and maintain the coolant system to ensure proper flow and filtration.

10. What are the advancements and emerging trends in optical lathe technology?

- Ultra-precision machining: Techniques and equipment for achieving sub-micron level accuracy.

- Laser machining: Non-contact machining using lasers for precise cutting and engraving of optical components.

- Automated optical inspection: Advanced inspection systems for real-time monitoring and quality control.

- Artificial intelligence (AI): Integration of AI algorithms for process optimization and predictive maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Optical Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Optical Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Optical Lathe Operators are highly skilled professionals. Their primary focus is on the operation of optical lathes, specialized machines utilized in the production of precision optical components and devices. It demands expertise in optics, machining, and precision measurement techniques.

1. Operating Optical Lathes

Optical Lathe Operators are the masterminds behind the operation of optical lathes, executing complex machining processes with finesse. Their duties include setting up and aligning the lathe, selecting appropriate tooling, and determining optimal cutting parameters to achieve precise dimensions and surface finishes on optical components.

- Prepare and secure optical workpieces within the lathe’s chuck or collet.

- Calibrate and align lathe components, ensuring accuracy and minimizing errors.

2. Precision Machining

Optical Lathe Operators leverage their dexterity and knowledge to perform intricate machining tasks on various optical materials, including glass, crystals, and ceramics. They employ cutting tools, such as diamond-tipped inserts, to shape and polish surfaces with extreme precision.

- Execute precise cutting, grinding, and polishing operations to create optical components that meet stringent specifications.

- Maintain sharp cutting tools and ensure their proper condition for optimal performance.

3. Quality Control

Ensuring the highest quality standards is paramount for Optical Lathe Operators. They meticulously inspect finished optical components using specialized measuring instruments like interferometers and profilometers. Their expertise enables them to identify and rectify any deviations from desired specifications.

- Conduct thorough inspections to assess component dimensions, surface quality, and optical performance.

- Implement corrective actions to resolve discrepancies and guarantee product compliance.

4. Machine Maintenance

Optical Lathe Operators play a vital role in maintaining the optimal performance of their lathes. They perform routine maintenance tasks, including cleaning, lubrication, and minor repairs, to ensure smooth operation and longevity of the equipment.

- Clean and lubricate lathe components to prevent wear and tear.

- Identify and resolve minor mechanical issues, minimizing downtime and maintaining productivity.

Interview Tips

Preparing for an interview can help you ace it. Here are some tips to shine during your Optical Lathe Operator interview:

1. Research the Position and Company

Thoroughly research the specific optical lathe operator position and the company you’re applying to. This will give you a deep understanding of the company’s culture, values, and the specific responsibilities of the role.

- Visit the company’s website and social media pages to gather information about their products, services, and work environment.

- Review the job description carefully, paying attention to the required skills, experience, and qualifications.

2. Highlight Your Skills and Experience

Emphasize your optical lathe operating skills, experience with precision machining techniques, and quality control procedures. Quantify your accomplishments and use specific examples to demonstrate your abilities.

- Describe your experience in operating different types of optical lathes and the materials you’ve worked with.

- Showcase your expertise in precision machining techniques, such as grinding, polishing, and cutting.

3. Practice Your Answers

Prepare thoughtful and concise answers to common interview questions. Practice delivering your responses clearly and confidently. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

- Prepare answers to questions about your work experience, skills, and why you’re interested in the position.

- Practice answering questions related to optical lathe operation, precision machining, and quality control.

4. Prepare Questions for the Interviewers

Asking insightful questions during the interview shows your interest and engagement. Prepare questions that demonstrate your understanding of the role, the company, and the industry.

- Ask about the company’s commitment to quality and precision in optical manufacturing.

- Inquire about opportunities for professional development and training.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally and arrive punctually for your interview. This demonstrates respect for the interviewers and the company

- Choose attire that is appropriate for an office setting.

- Be on time, or even a few minutes early, to show your punctuality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Optical Lathe Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!